A driving method of intelligent material combination for flexible grasping mechanism

A technology of combined driving and intelligent materials, applied in the directions of manipulators, manufacturing tools, chucks, etc., can solve the problems of low driving frequency, low actuation speed, poor stability, etc., and achieve the effect of fast movement speed and large opening and closing range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

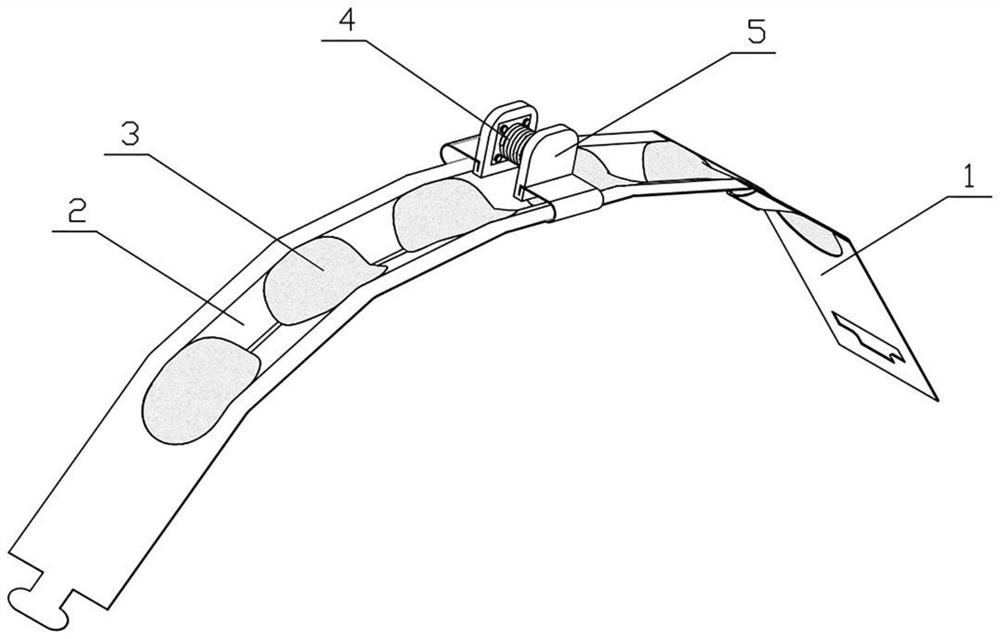

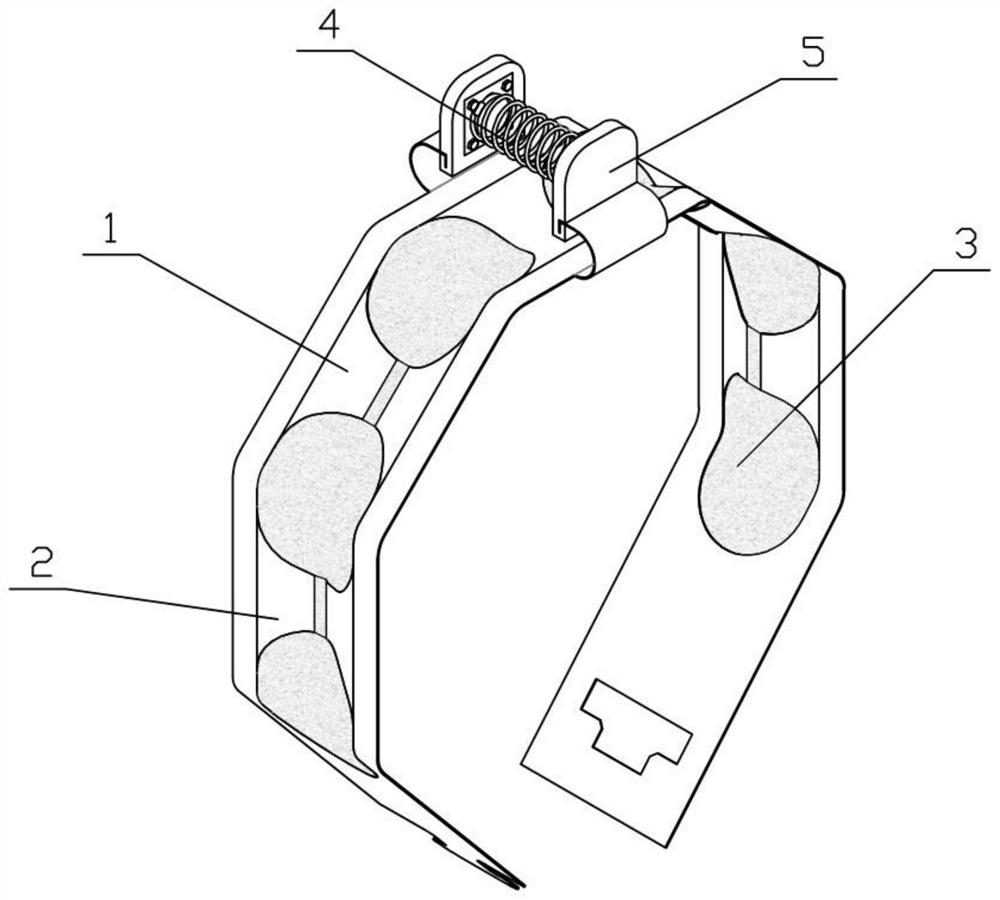

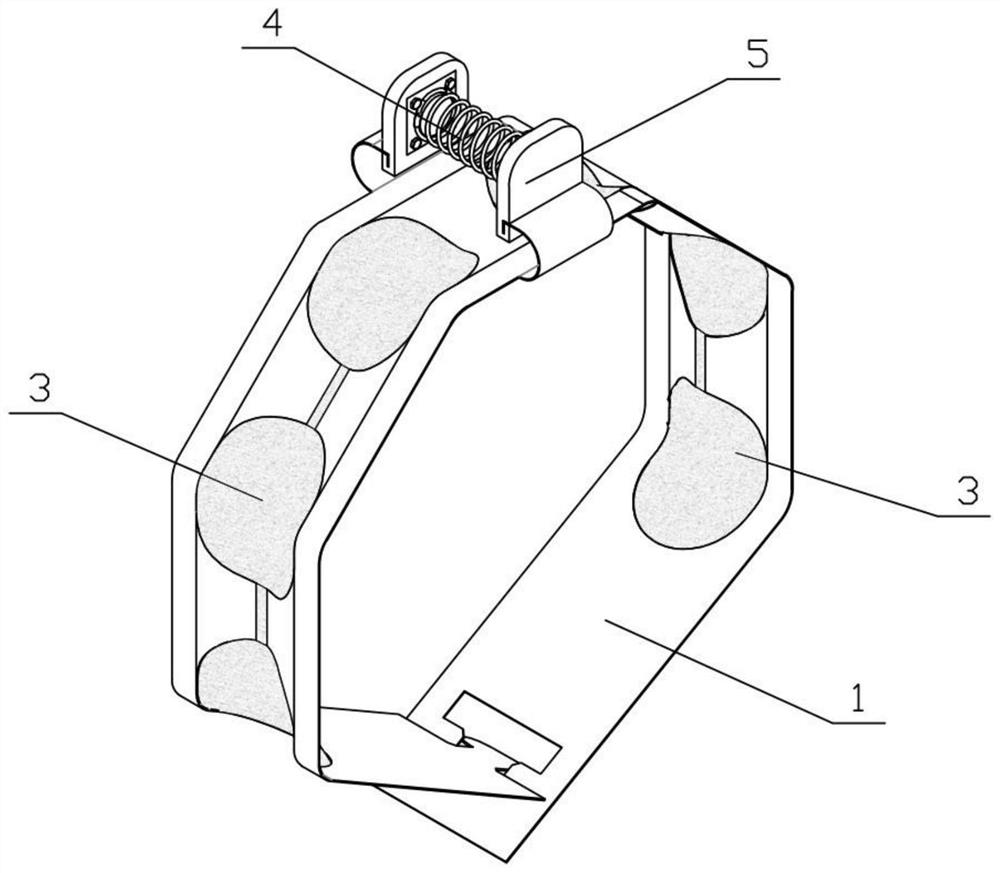

[0033] Combine below Figures 1 to 8 Describe this embodiment, a smart material combination driving method for a flexible catch mechanism, the method includes the following steps:

[0034] S1: The flexible linear drive 4 stretches to drive the flexible gripper 1 to retract;

[0035] S2: The dielectric elastomer film driving device drives the flexible gripper 1 to be further closed and locked.

[0036] When driven by the flexible linear actuator 4 alone, the flexible gripper 1 opens and closes with a large range and fast movement speed; when driven by the dielectric elastomer film drive device alone, the flexible gripper 1 can fine-tune the end state when it is folded, so that the end is established effectively Connected, can be completely closed; it can be driven by a combination of flexible linear actuator 4 and dielectric elastomer film drive device, combining the advantages of flexible linear actuator 4 drive and dielectric elastomer film drive device, so that the flexible...

specific Embodiment approach 2

[0037] Combine below Figures 1 to 8 Describe this embodiment, this embodiment will further explain Embodiment 1, the flexible gripper 1 includes a flexible gripper long arm 101 and a flexible gripper short arm 102, two flexible grippers extend from the middle of the flexible gripper long arm 101 Hand short arm 102.

specific Embodiment approach 3

[0038] Combine below Figures 1 to 8 This embodiment will be described. This embodiment will further describe the second embodiment. The dielectric elastomer film driving device includes a dielectric elastomer film 2 and a flexible electrode 3, and a layer of The dielectric elastomer film 2 and the flexible electrode 3 are attached to both sides of each layer of dielectric elastomer film 2; and the dielectric elastomer film 2 is adhered to the flexible gripper 1, which will significantly improve the structural damping of the flexible gripper 1, Therefore, the oscillation amplitude and oscillation time of the flexible gripper 1 when the shape memory alloy spring is driven are effectively reduced, and the structure quickly enters a stable state, and the grasping is completed smoothly. The dielectric elastomer film 2 is a transparent superelastic film with adhesive on both sides, which is attached to both sides of the flexible gripper long arm 101 including the flexible gripper h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com