Injection mold with limiting structure

A technology of injection mold and limit structure, which is applied in the field of injection mold, can solve the problems of upper mold and lower mold impact, affect the quality of injection molded parts, increase the unqualified rate, etc., and achieve the effect of improving the qualified rate, preventing displacement and maintaining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

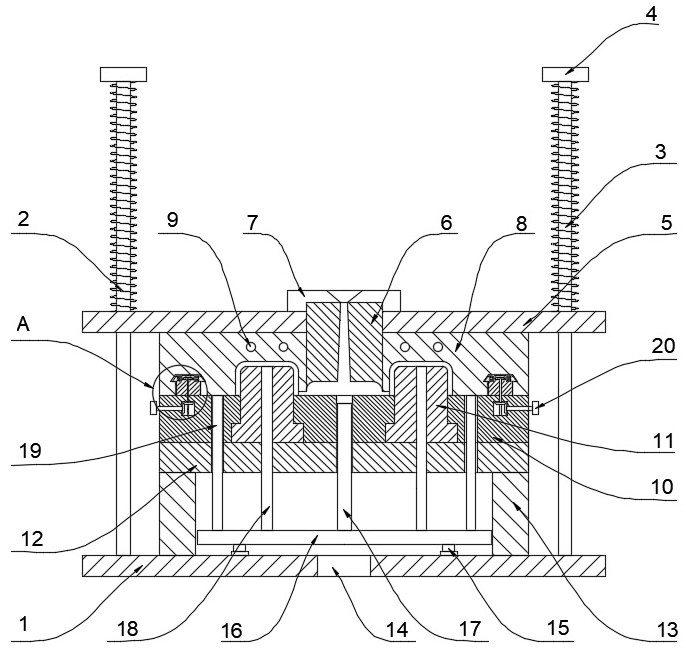

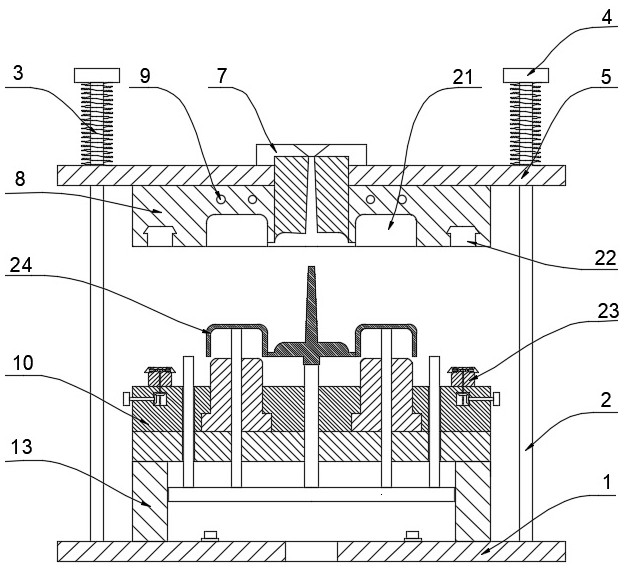

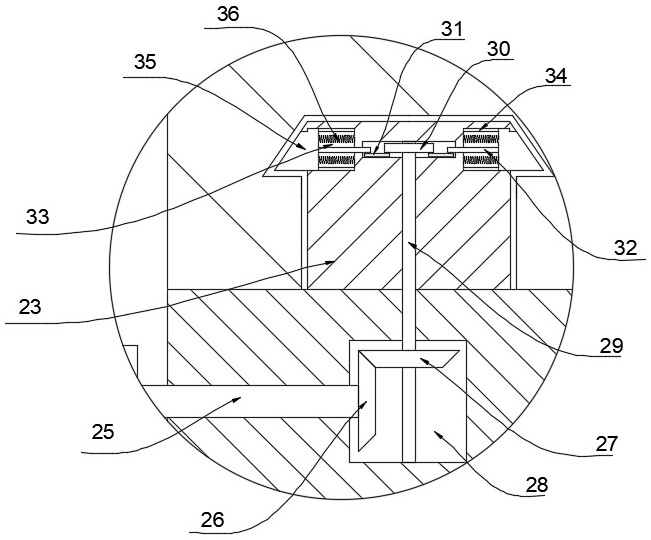

[0022] refer to Figure 1-4 , an injection mold with a position-limiting structure, comprising a lower base plate 1, straight rods 2 are welded and fixed at the top four corners of the lower base plate 1, the top of the straight bar 2 is welded and fixed with a limit block 4, and the bottom of the limit block 4 is welded and fixed There is a return spring 3, the straight rod 2 is slidingly connected with an upper baffle 5, the other end of the return spring 3 is welded and fixed on the upper baffle 5, the return spring 3 is sleeved on the straight rod 2, and the bottom of the upper baffle 5 is welded and fixed with an upper Die 8, the top of lower bottom plate 1 is welded and fixed with support block 13, and support plate 12 is fixed with bolt above support block 13, and support plate 12 top is provided with fixed plate 10, and fixed plate 10 is connecte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap