A kind of tread rubber based on synthetic rubber and its preparation method and application

A synthetic rubber and tread rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of inability to produce aviation tire natural rubber and restrict development, and achieve the promotion of localization process and excellent wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

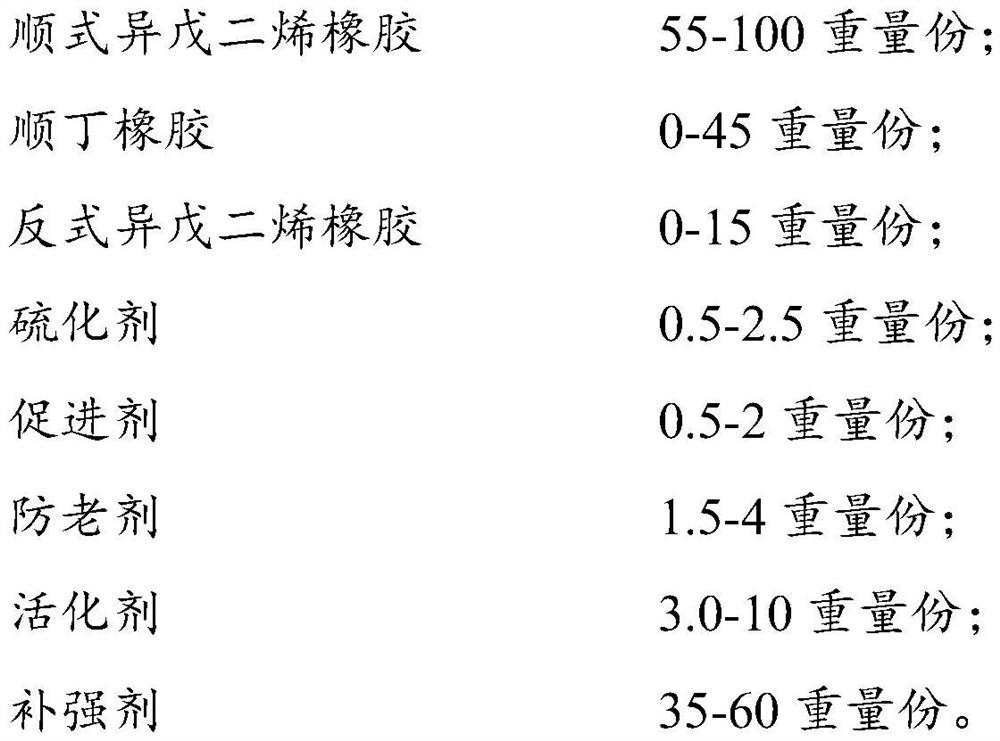

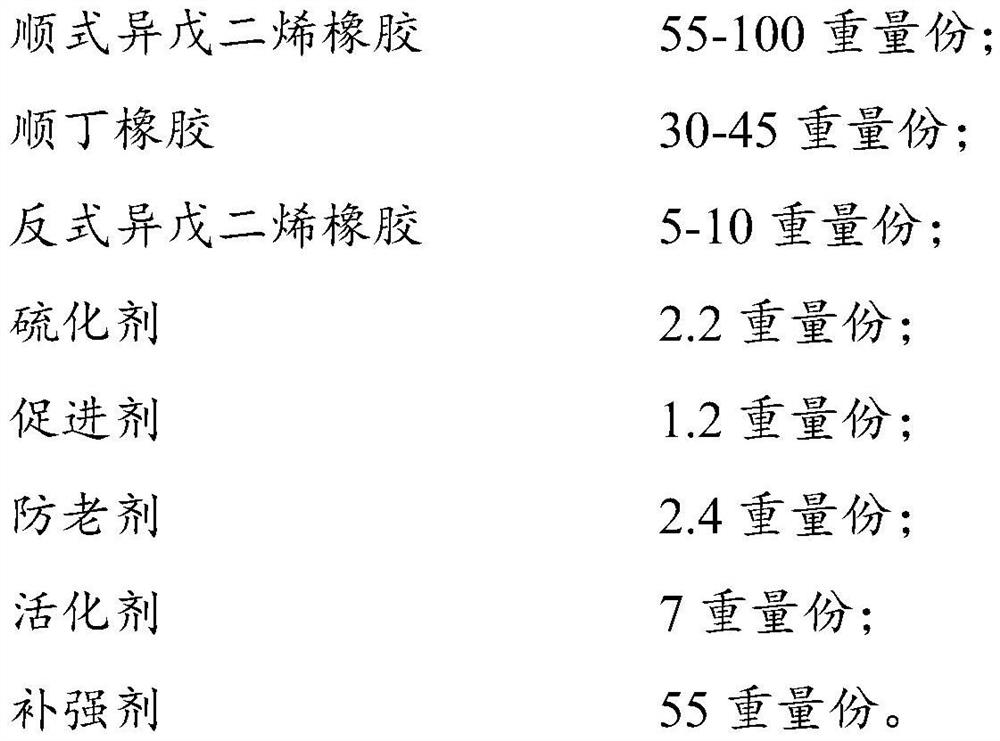

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the tread rubber of the present invention taking synthetic rubber as the base glue may further comprise the steps:

[0052] Step 1, taking each component by proportioning;

[0053] Step 2. Put cis-isoprene rubber, butadiene rubber and trans-isoprene rubber into an internal mixer with a temperature of 50-80°C and a rotation speed of 20-70rpm, and banbury for 1-3min; the preferred temperature The temperature is 50°C, the rotating speed is 25rpm, and the banburying time is 3min;

[0054] Step 3. Add anti-aging agent, activator, reinforcing agent and auxiliary agent to the internal mixer in step 2. After banburying for 5-10 minutes, discharge the glue and release the film, and park the film at 30-50°C for 18-24 hours , to obtain the banburying film; the preferred banburying time is 7min, and the film is parked at 30°C for 24h;

[0055] Step 4: Put the banbury rubber sheet obtained in Step 3 on the rolling mill with a roll temperature of 40-80°C, ...

Embodiment 1-7 and comparative example 1-2

[0062] The formulations of the tread rubbers of Examples 1-7 and Comparative Examples 1-2 are shown in Table 1. The preparation method is:

[0063] Step 1, taking each component by proportioning;

[0064] Step 2, putting natural rubber, cis isoprene rubber, butadiene rubber and trans isoprene rubber into an internal mixer with a temperature of 70° C. and a rotating speed of 25 rpm, and banburying for 3 minutes;

[0065] Step 3. Add anti-aging agent, activator, reinforcing agent and auxiliary agent to the internal mixer in step 2. After banburying for 7 minutes, discharge the glue and release the film. The film is parked at 30°C for 24 hours to obtain the banbury film;

[0066] Step 4: Put the banbury rubber sheet obtained in Step 3 on the rolling mill with a roll temperature of 50°C, and add vulcanizing agent and accelerator during the rolling process. After the rolling is uniform, the sheet is released, and the film is parked at 30°C for 24 hours to obtain Mixed rubber shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com