Wallboard pressing and fixing device

A technology for fixing devices and wall panels, which is applied to buildings and building structures, etc., can solve problems such as uneven pressing, arching of wall panels, and insufficient stability of supporting devices, achieve convenient opening and closing, and reduce floor space. , the effect of easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to more clearly illustrate the embodiments of the present invention and the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations. In addition, the belonging of the design orientation only indicates the relative positional relationship between the components, not the absolute positional relationship.

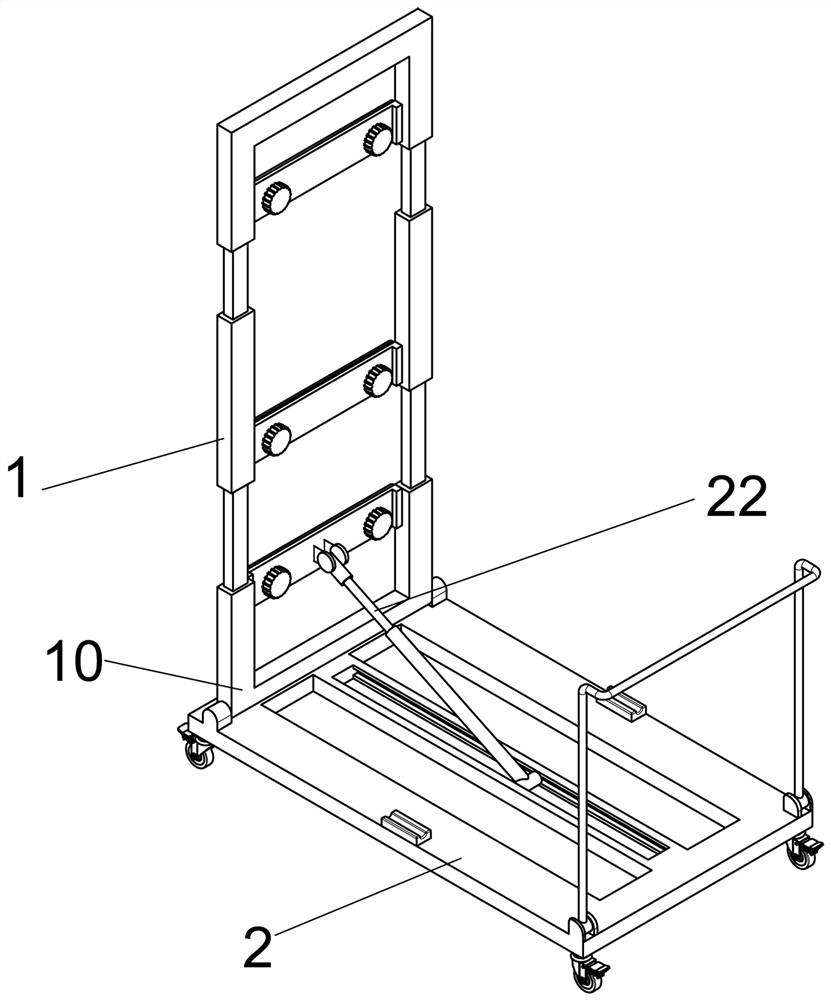

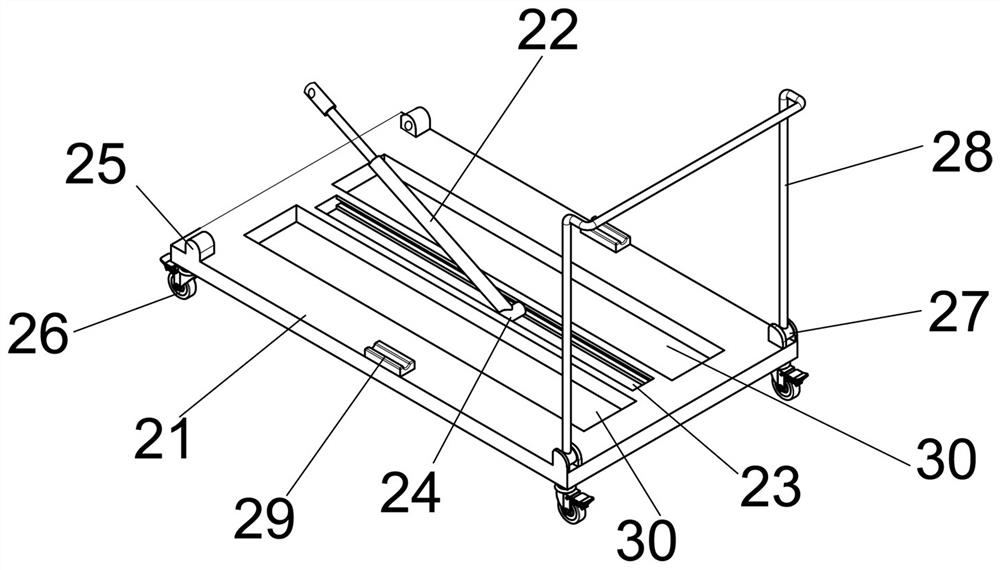

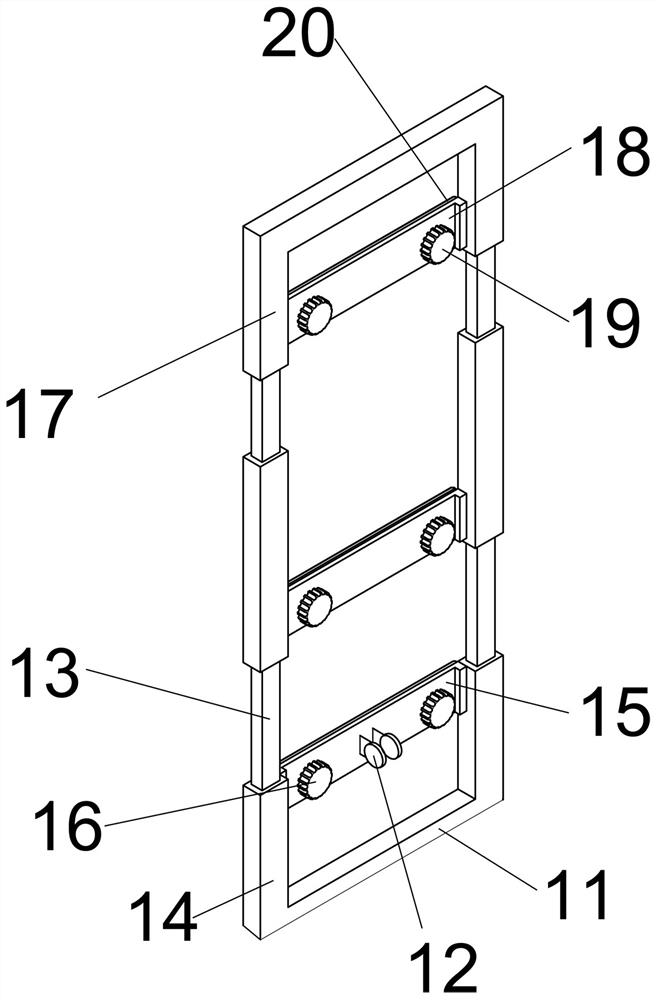

[0034] see figure 1 , figure 2 , in an embodiment of the present invention, a wallboard pressing and fixing device is characterized in that it includes a pressing device 1 that can conflict with the wallboard, a supporting device 2 that provides support for the pressing device 1, and the supporting device 2 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com