Self-healing edge sealing process suitable for 22-degree handle-free door plate

A self-healing, handle-free technology, used in special equipment for doors/windows, door leaves, windows/doors, etc., it can solve the swelling deformation, bulging, edge wear and scratches of the edge strip finish and core board. Damage and other problems, to achieve the effect of high integrity, high sealing, good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

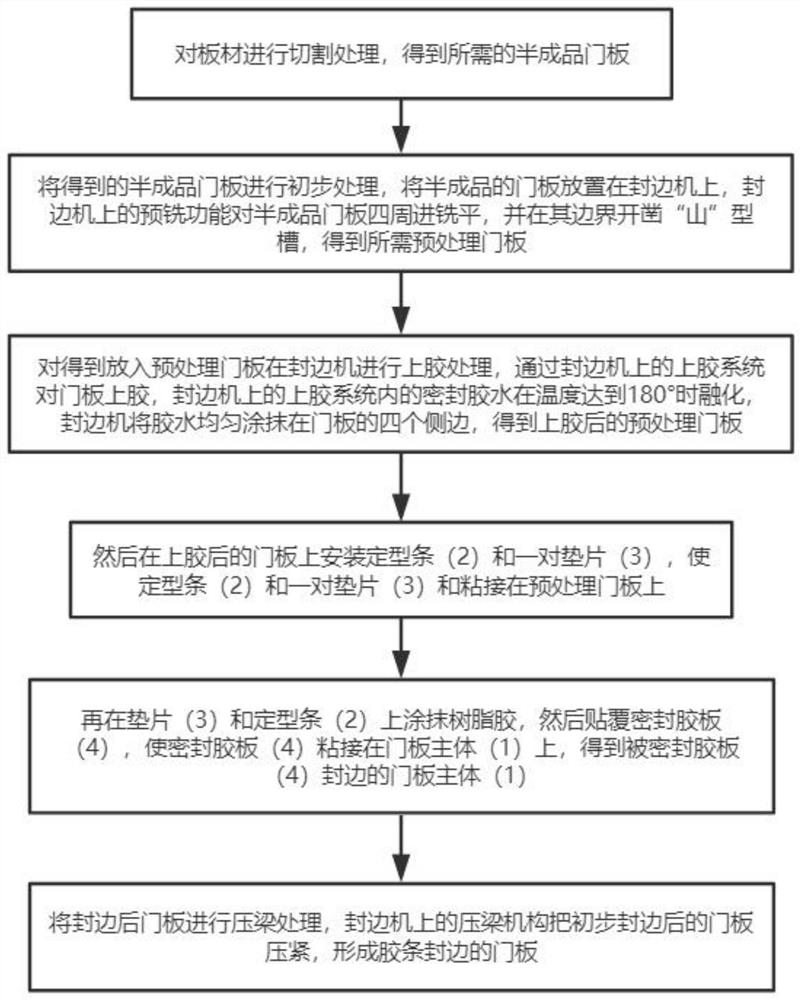

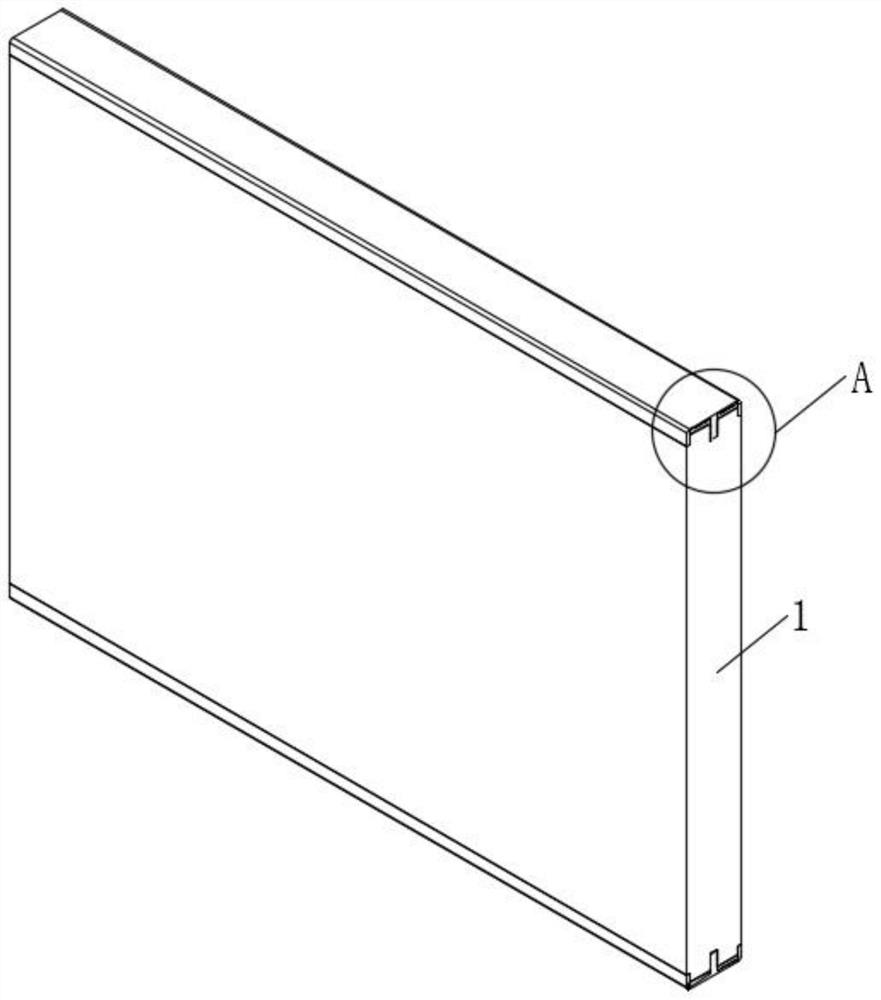

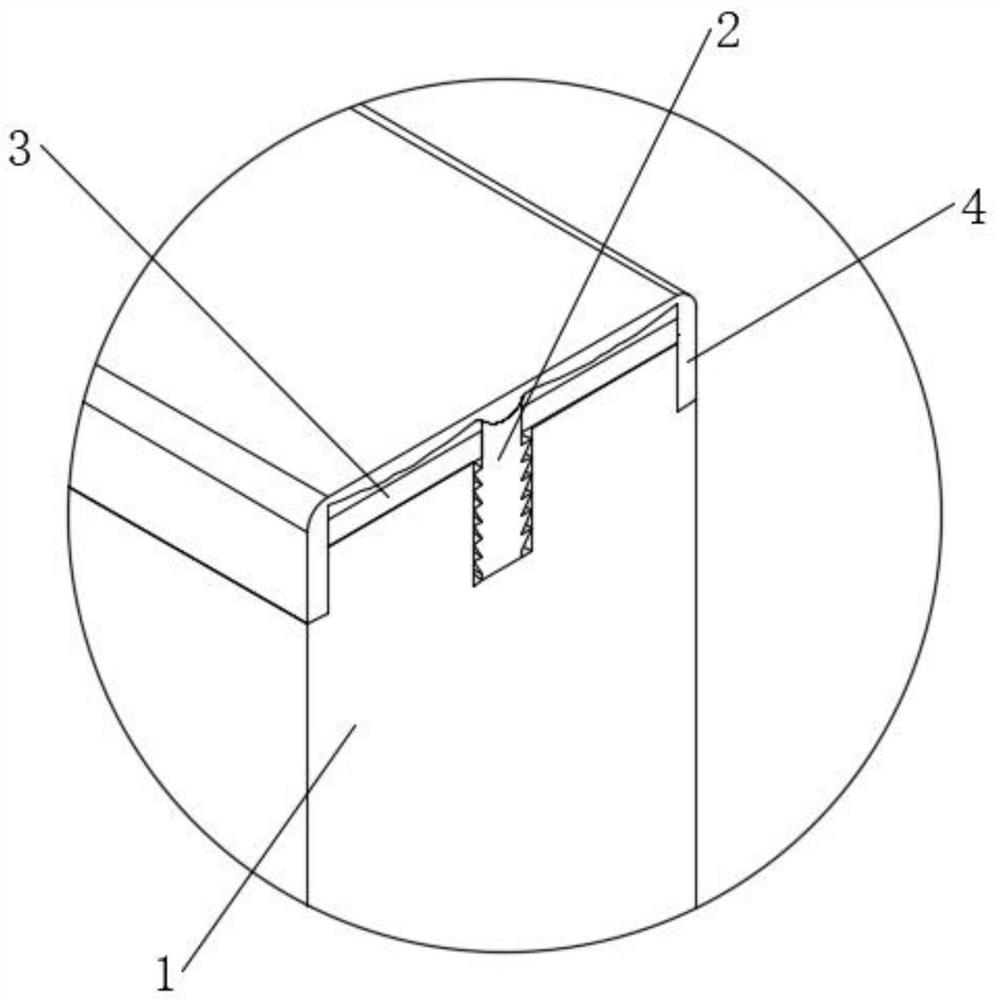

[0041] see Figure 1-3 , a self-healing edge banding process suitable for 22-degree handle-free door panels, the specific process is:

[0042] S1, cutting the board to obtain the required semi-finished door board;

[0043] S2, preliminarily process the obtained semi-finished door panels, place the semi-finished door panels on the edge banding machine, the pre-milling function on the edge banding machine will mill and flatten the surrounding of the semi-finished door panels, and dig "mountain" shaped grooves on its borders to obtain the required Pretreatment of door panels;

[0044] S3, put the pretreated door panel into the edge banding machine for gluing treatment, glue the door panel through the gluing system on the edge banding machine, and the sealing glue in the gluing system on the edge banding machine melts when the temperature reaches 180 °, The edge banding machine applies the glue evenly on the four sides of the door panel to obtain the pretreated door panel after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com