Motor rotor, motor and motor rotor installation method

A technology of a motor rotor and an installation method, which is applied to electromechanical devices, manufacturing motor generators, and manufacturing stator/rotor bodies, etc., can solve the problems of high cost of rotor cores and easy bolts to fall off, so as to save processing costs, reduce losses, The effect of reducing the risk of local micro-vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below by means of specific examples, but the present invention is not limited to the scope of the following examples.

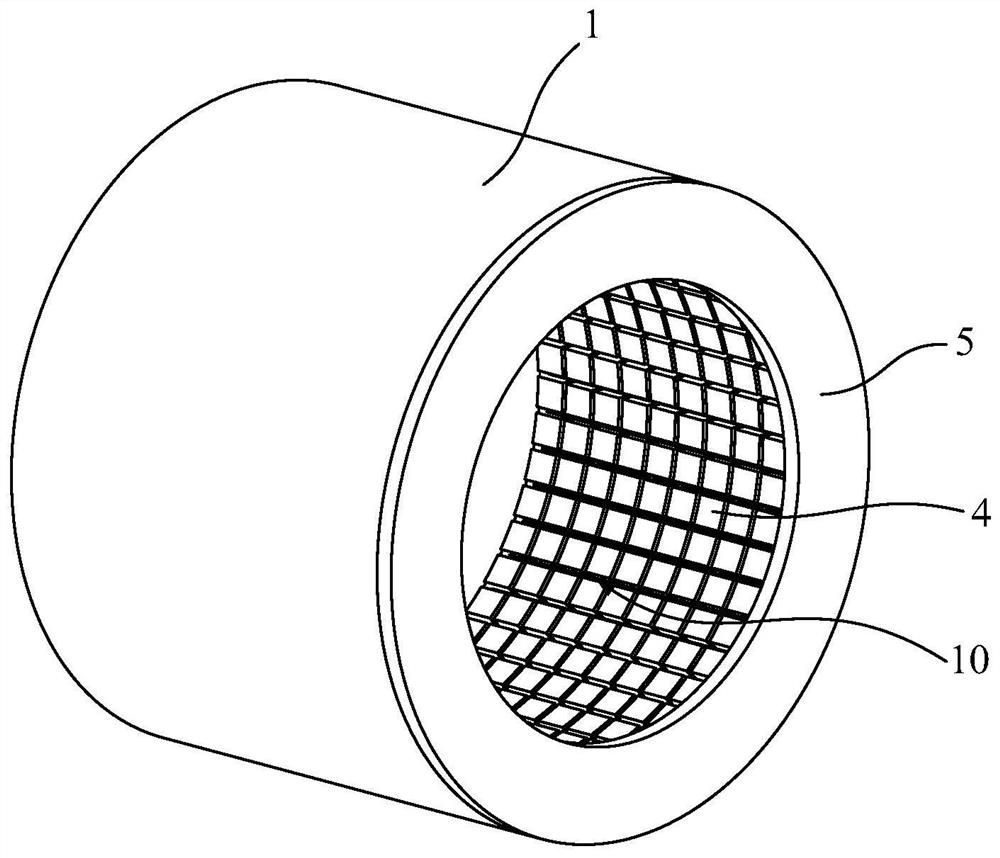

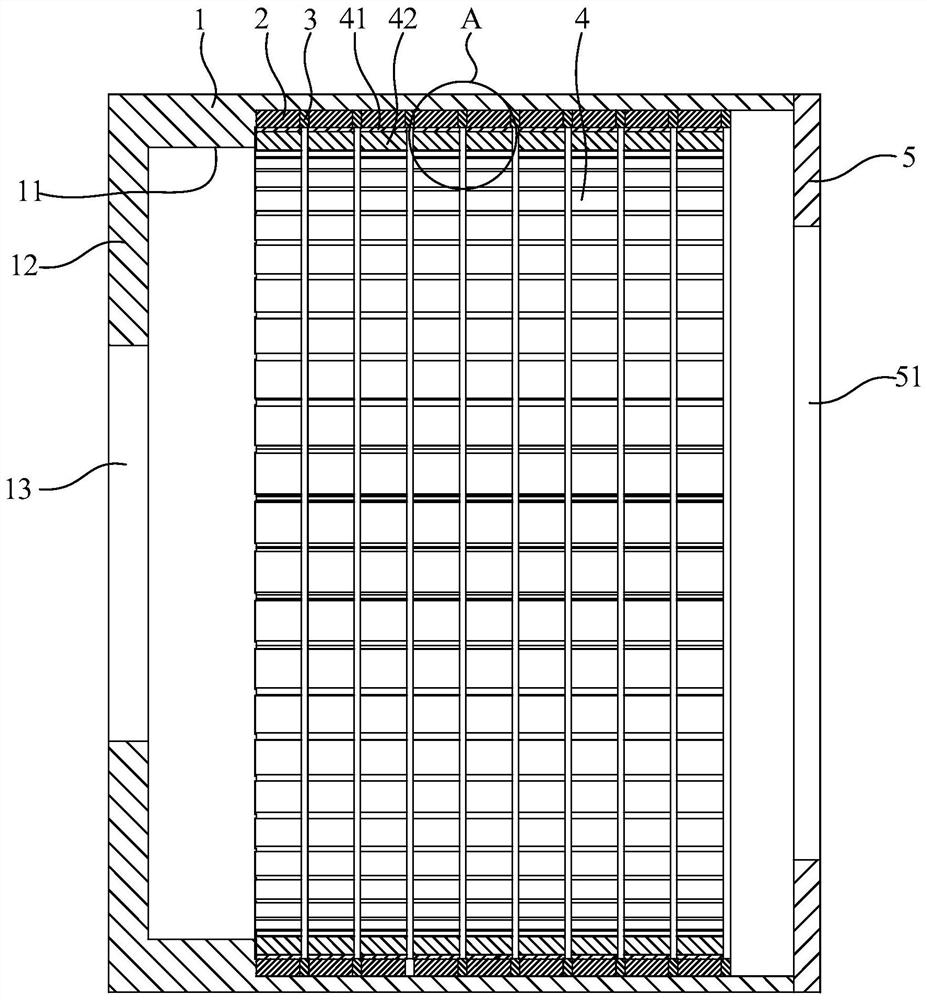

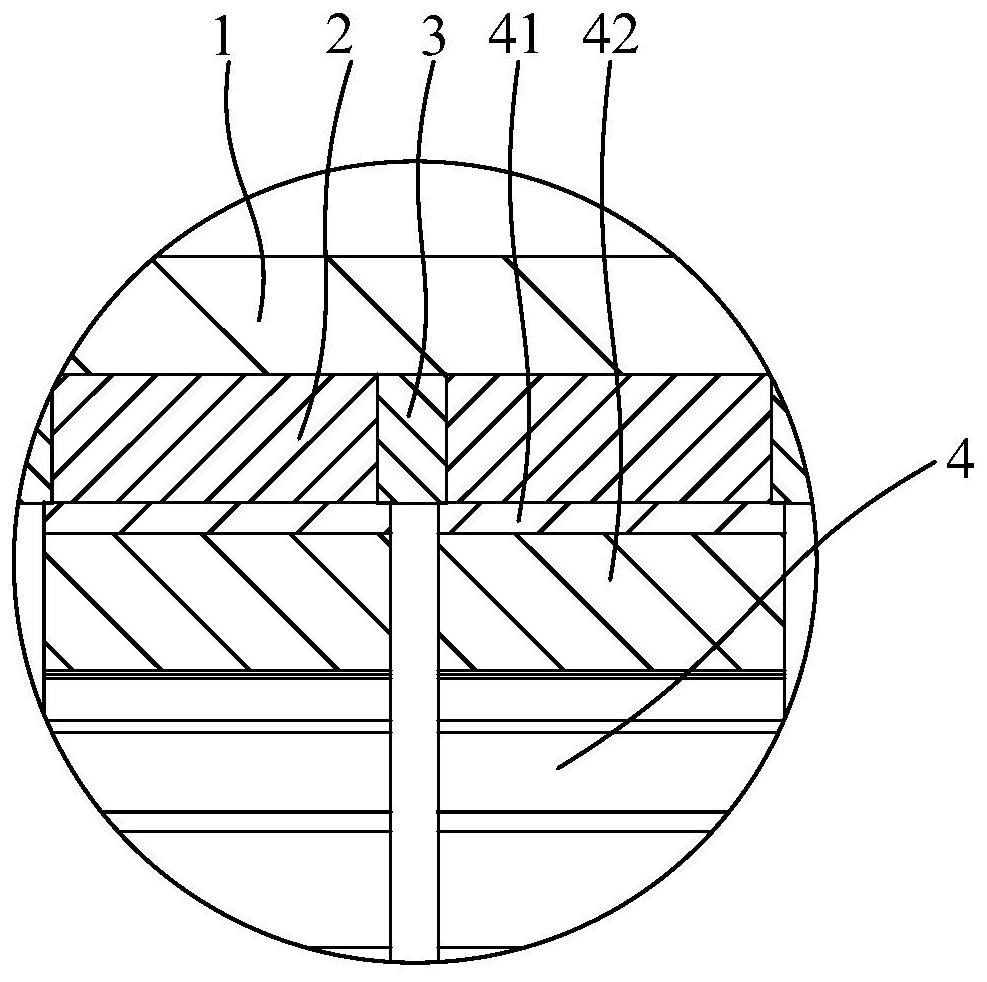

[0073] Such as Figure 1-5 As shown, it is a motor rotor of this embodiment, including a rotor house 1. There is a cylindrical cavity 10 extending axially along the rotor house 1 inside the rotor house 1. The end of the rotor house 1 has a hole communicating with the cylindrical cavity 10. Opening, the motor rotor also includes a plurality of rotor cores 2 and a plurality of bridging ribs 3, the rotor cores 2 and bridging ribs 3 are ring structures, and the outer peripheral surface of the rotor core 2 and the outer peripheral surface of the bridging ribs 3 All are attached to the inner peripheral surface of the cylindrical cavity 10; multiple rotor cores 2 and multiple bridging ribs 3 are arranged at intervals along the axial direction of the cylindrical cavity 10, and the sides of the bridging ribs 3 pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com