Composite melt-blown cloth production device and production method of composite melt-blown cloth

A technology of melt-blown cloth and cloth, which is applied to the device, coating, textile and paper making of the surface coating liquid, etc., can solve the problems of affecting the normal coating of cloth, laborious operation, and troublesome cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

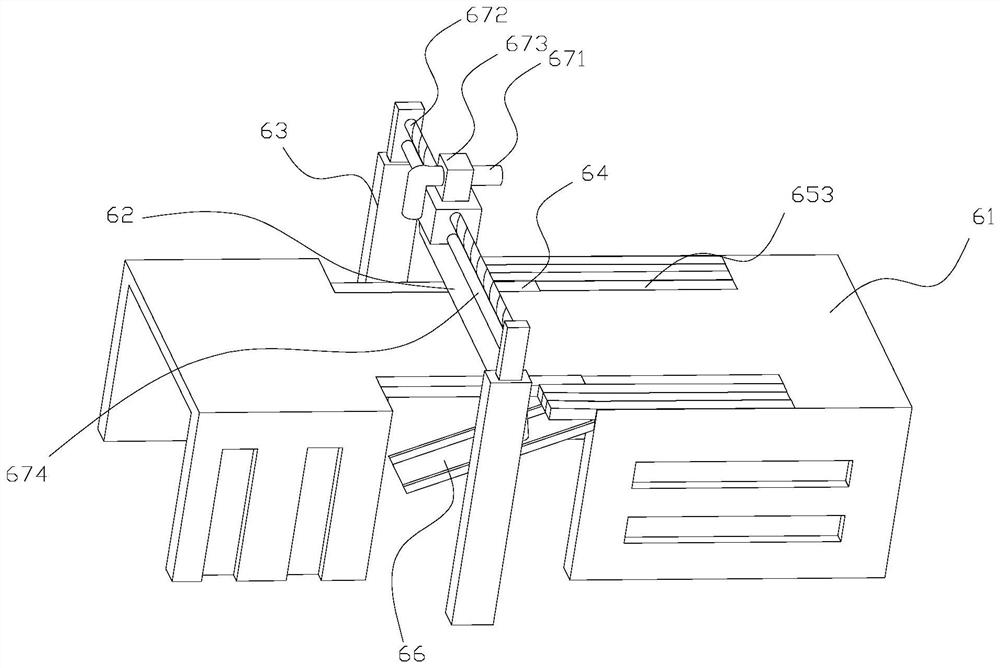

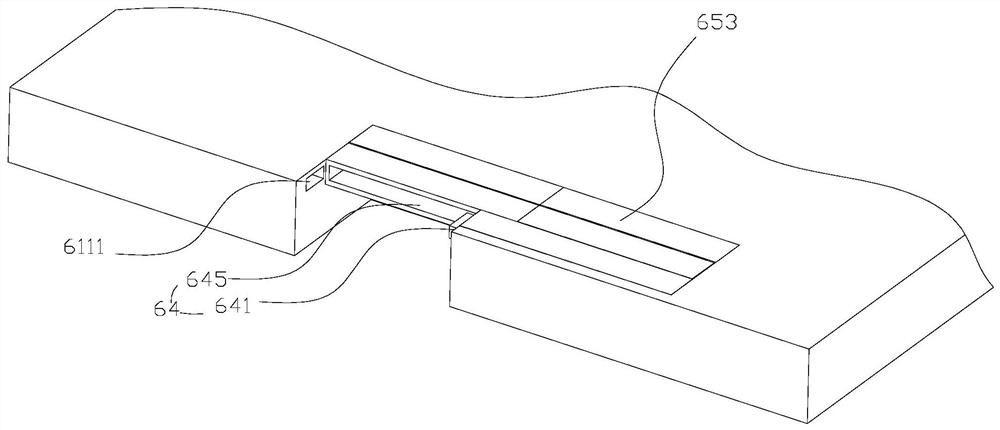

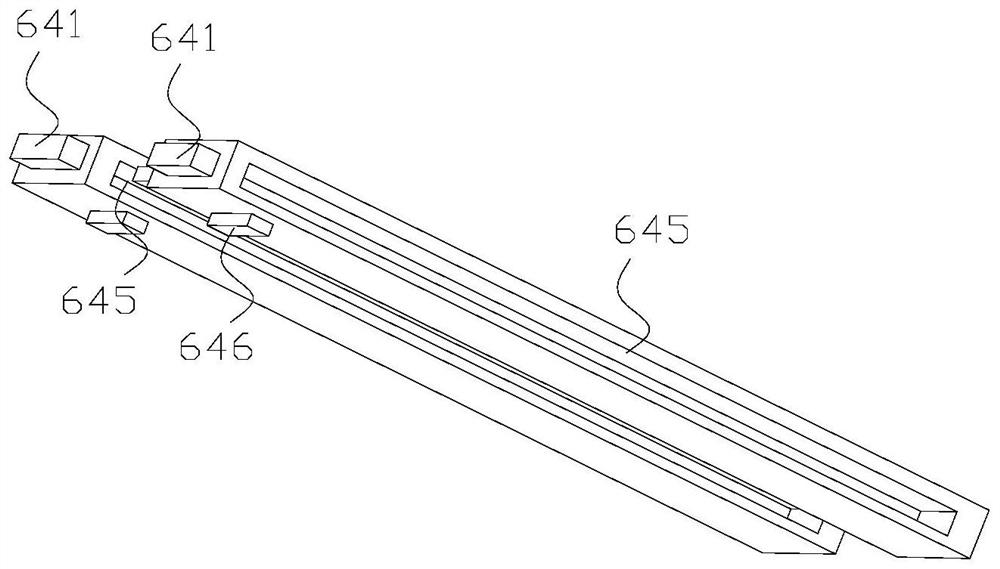

[0084] Such as Figure 1-4 As shown, this embodiment discloses a coating device, which includes a coating platform 61 and a scraper 62 . The scraper 62 is arranged above the coating platform 61, specifically on the coating platform support 63, there is a paint gap between the bottom of the scraper 62 and the top surface of the coating platform 61, and cloth can pass through the paint gap.

[0085] Notches 611 are symmetrically formed on both sides of the coating platform 61 in the width direction, and the projection of the scraper 62 in the vertical direction penetrates the notches 611 . At the rear end of the notch 611 is provided a placing groove with an opening upward. The placement slot communicates with the notch 611 and the inner sidewall of the placement slot is flush with the inner sidewall of the notch 611 . A support plate 613 is provided at the front end of the placement slot.

[0086] Such as figure 2 As shown, a mounting socket 6111 is opened on the front inn...

Embodiment 2

[0115] Such as Figure 9 As shown, this embodiment discloses a composite melt-blown fabric production device, which includes a feeding device 1, a coating device 6, a drying device 7, and a winding device 8 in sequence according to the process flow from front to back. Wherein, the drying device and the winding device are all prior art, and the drying device is preferably a tunnel oven. The coating device 6 is preferably the coating device of the above embodiment, and may also be other prior art.

[0116] The feeding device 1 is used to transport the cloth to the coating device 6, the coating device 6 is used to coat the cloth, the drying device 7 is used to dry the coated cloth, and the winding device 8 is used to Wind the dried fabric.

[0117] Such as Figure 10 , 11 As shown, the material loading and feeding device 1 includes an overturned material loading platform, a lifting platform 12 , and a fastening device 13 . The top of the flipping loading platform is a placem...

Embodiment 3

[0144] This embodiment discloses a production method of a composite melt-blown cloth, comprising the following steps:

[0145] Step 1. Feed the PP melt-blown cloth roll to the feeding device;

[0146] Step 2. Select the number of widened plates in each gap according to the width of the PP meltblown cloth, and move the outermost pair of widened plates in the selected widened plates in each gap until the selected widened plates are aligned Move forward until the installation tenon fits with the installation mortise and tenon, and the corresponding cover plate is lifted and closed to adjust the width of the coating area;

[0147] Step 3, coating the PP melt-blown cloth;

[0148] Step 4, the coated PP melt-blown cloth is dried;

[0149] Step 5, the dried composite melt-blown fabric is wound and unloaded.

[0150]Step one includes the following steps:

[0151] S11. Turn the overturned feeding platform until the placement surface is an inclined surface where the end far away fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com