Cross-border e-commerce logistics packer

A packer and e-commerce technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problem of not being able to paste the documents on the packaged fast goods, so as to save packaging plastics, improve work efficiency, and reduce labor costs. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

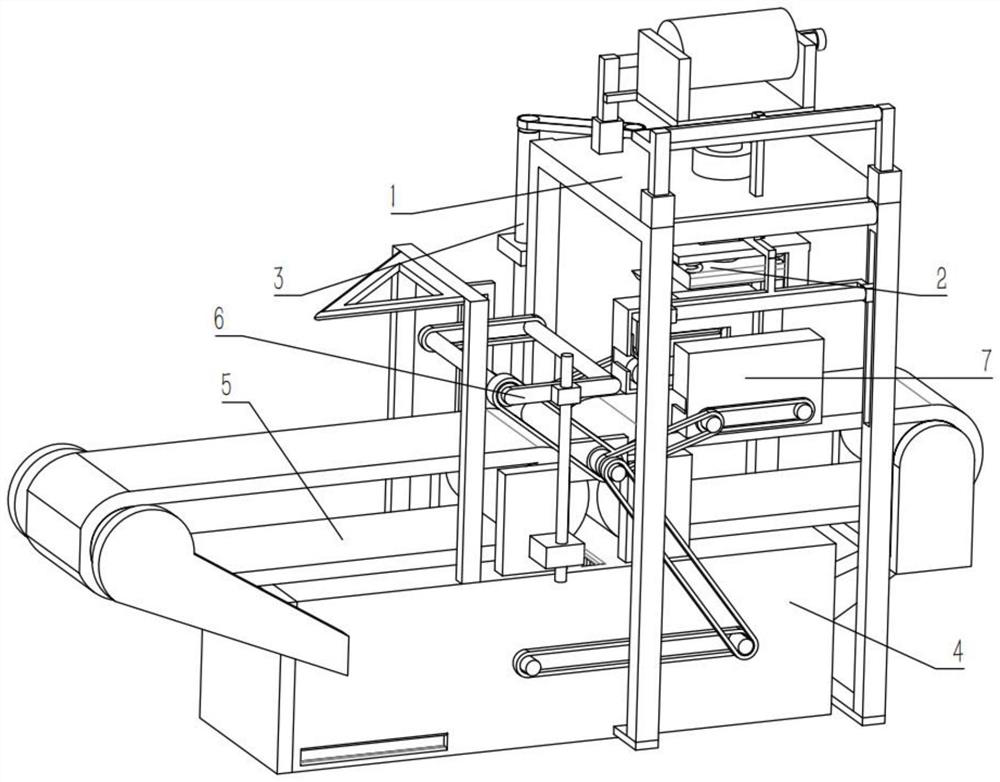

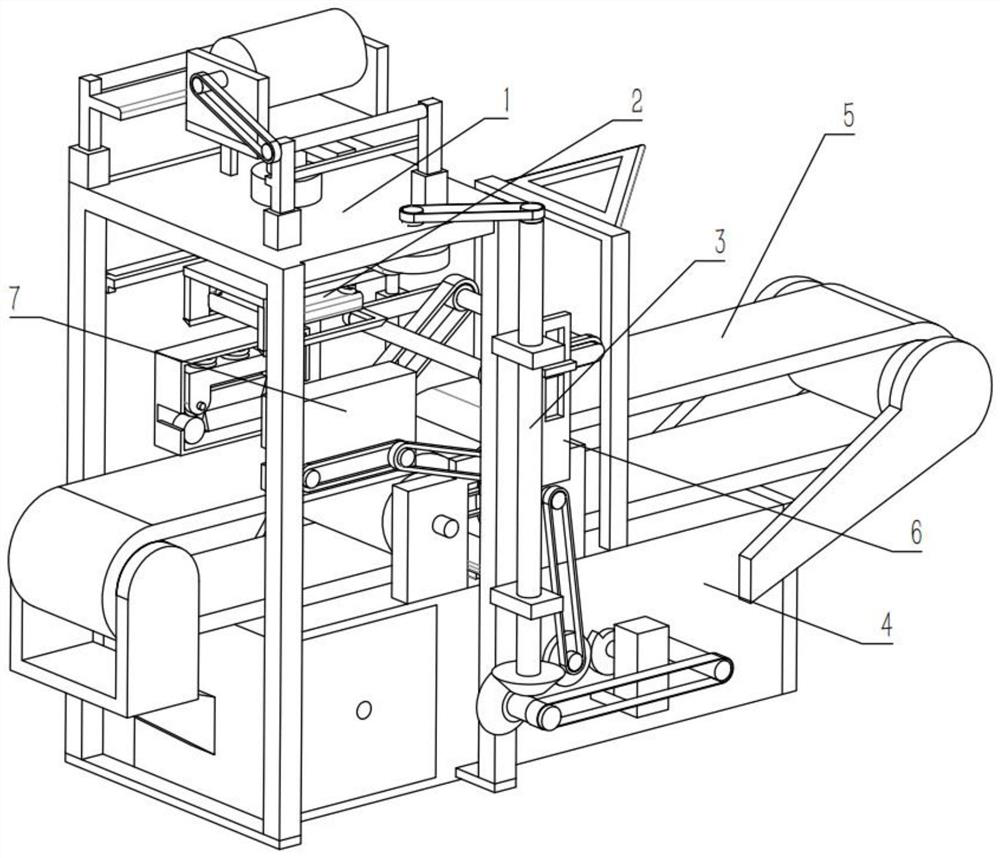

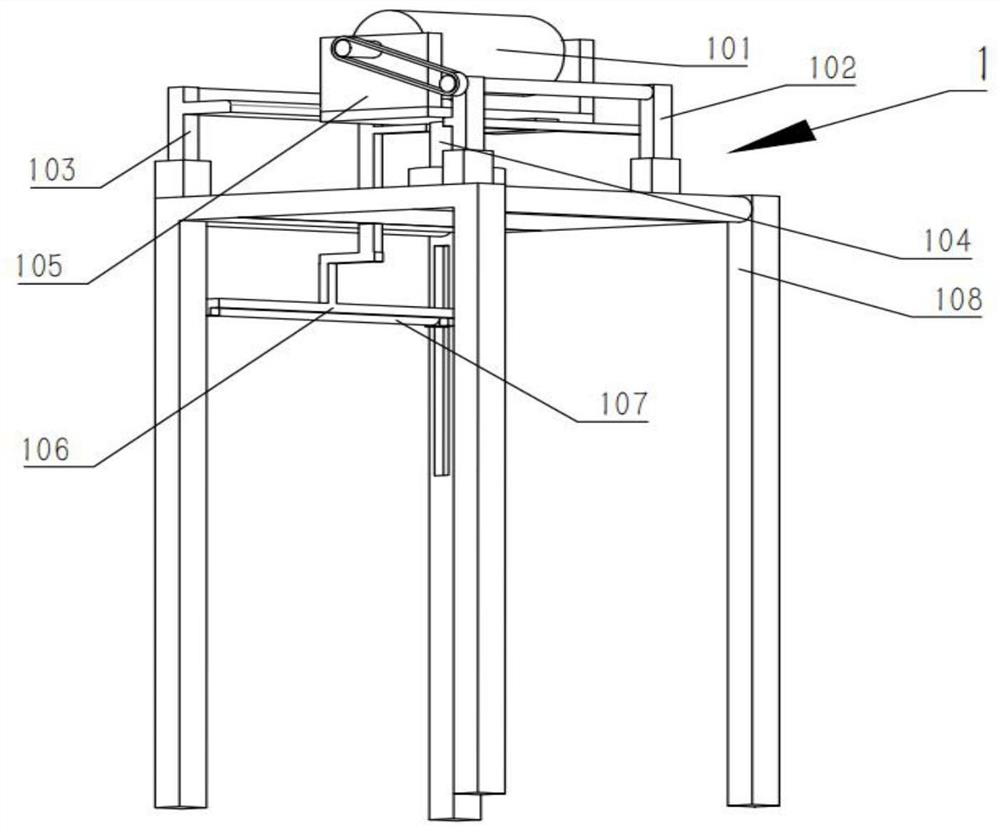

[0033] Combine below Figure 1-11Describe this embodiment, a cross-border e-commerce logistics packer, including a sticker structure 1 and a cutting mechanism 2, the sticker mechanism 1 includes a receipt placement cylinder 101, a recycling rack 102, a guide frame 103, a telescopic rod 104, and a base 105. Connect the sliding frame 106, the guide frame II 107 and the four-legged frame 108, the document placement cylinder 101 is rotatably connected to the base 105, the recovery frame 102 is slidably connected to the four-legged frame 108, and the guide frame 103 is slidably connected to the four-legged frame 108 , the telescopic rod 104 is fixedly connected to the four-legged frame 108, the base 105 is fixedly connected to the four-legged frame 108, the connecting sliding frame 106 is slidably connected to the four-legged frame 108, the guide frame II 107 is slidably connected to the four-legged frame 108, The shafts on the document placement cylinder 101 and the recovery frame...

specific Embodiment approach 2

[0036] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain Embodiment 1, the cutting mechanism 2 also includes a cutting frame 203, an electric heating cutter 204 and a spring 206, and the electric heating cutting knife 204 is fixedly connected to the cutting frame 203 , the upper and lower ends of the plurality of springs 206 are fixedly connected to the cutting frame 203 and the veneer 205 respectively;

[0037] The downward movement of veneer 205 drives a plurality of springs 206 to move downward, and the downward movement of a plurality of springs 206 drives the cutting frame 203 to move downward, and the downward movement of the cutting frame 203 drives the electric heating cutter 204 to move downward. The cutting knife 204 moves down to cut the plastic-wrapped courier, and then directly sticks together due to the heat to complete the packaging process. The courier can be packaged continuously and quickly, saving manpower and material...

specific Embodiment approach 3

[0039] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the second embodiment, the cross-border e-commerce logistics packager also includes a transmission mechanism 3, the transmission mechanism 3 includes a transmission shaft 301, a bevel gear shaft 302, a connecting shaft 303, Eccentric wheel 304, rotating rod 305 and rack 306, transmission shaft 301 and the bevel gear shaft 302 at the right end are driven by a belt, and the two bevel gear shafts 302 are meshed for transmission, and the bevel gear shaft 302 at the left end is fixedly connected on the connecting shaft 303. The shaft 303 and the eccentric wheel 304 are driven by a belt, the rotating rod 305 is rotatably connected to the eccentric wheel 304, the rotating rod 305 is rotatably connected to the rack 306, and the transmission shaft 301 and the two bevel gear shafts 302 are rotatably connected to the tripod 108 On the top, the eccentric wheel 304 is rotatably connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com