A kind of ultraviolet shielding agent and its preparation method and application

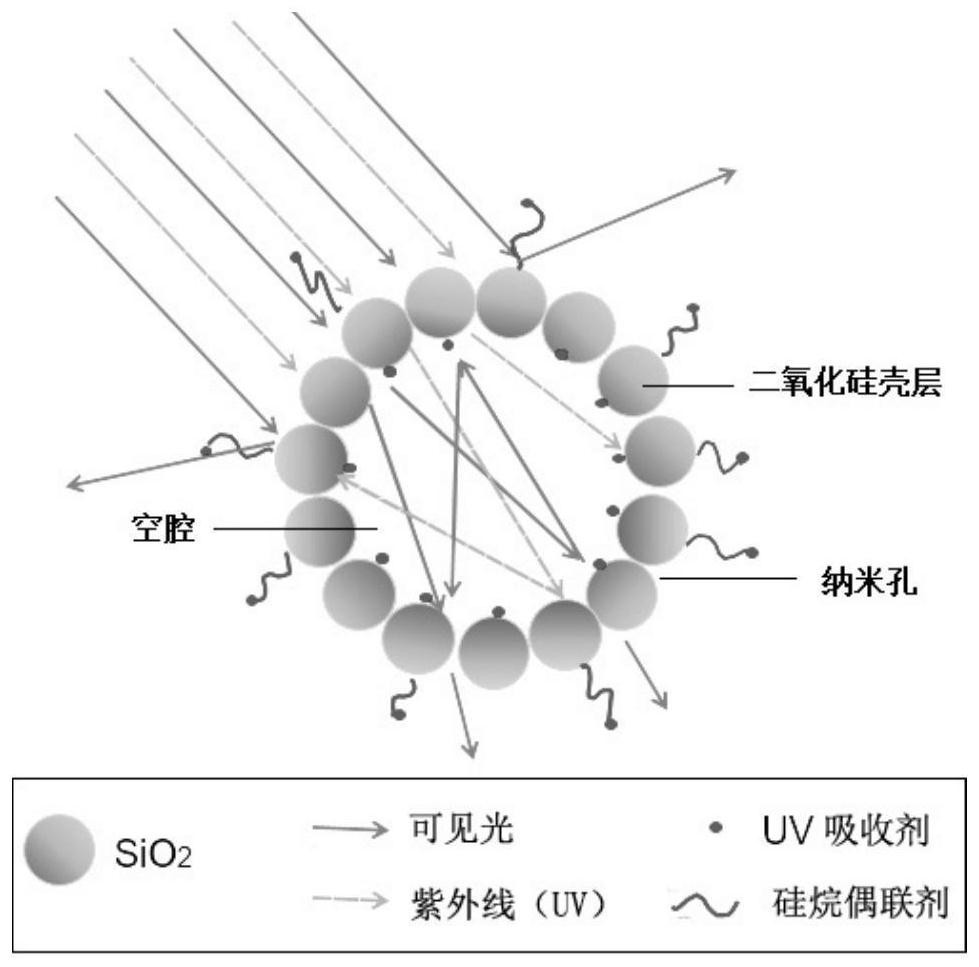

A technology of ultraviolet rays and shielding agents, which is applied in the field of ultraviolet shielding agents and their preparation, can solve the problems of easy migration of light stabilizers, short service life, and high requirements on the thickness of plastic products, so as to reduce migration and precipitation, improve absorption and shielding efficiency, Anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

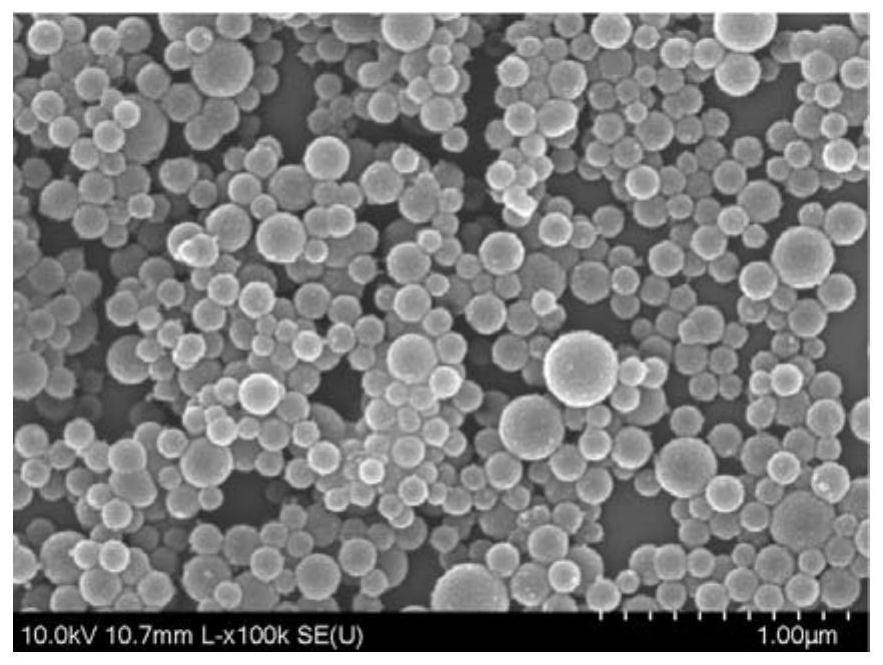

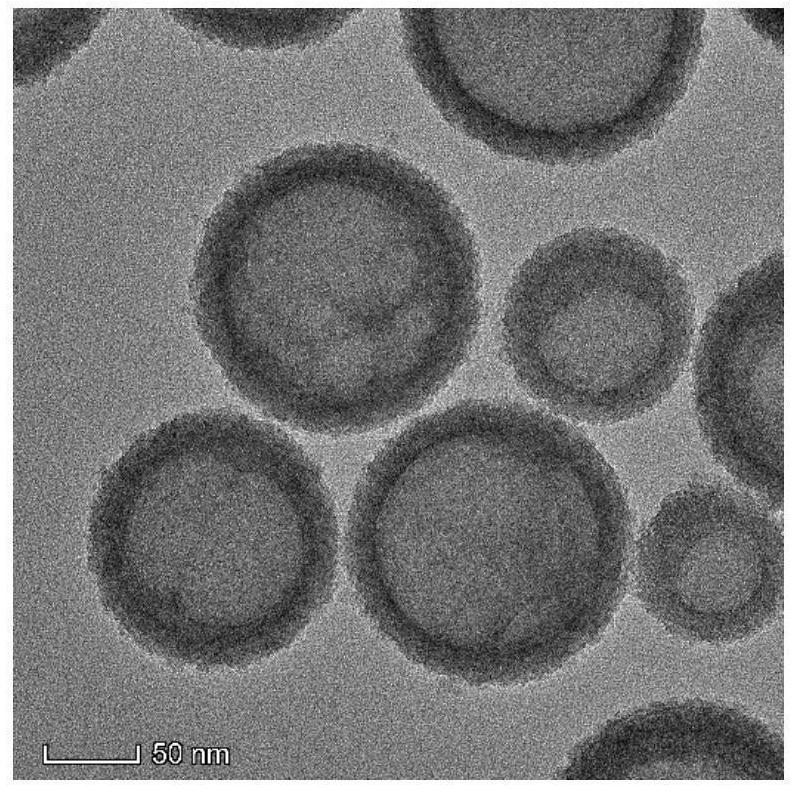

[0040] Embodiment 1 A kind of ultraviolet shielding agent

[0041] The preparation method of described ultraviolet shielding agent comprises the following steps:

[0042] S1. Formation of micellar template: Take 0.33g polyacrylic acid (molecular weight: 3000) and 0.2g 3-hydroxyphenyl benzoate, add 50mL of absolute ethanol to ultrasonic vibration, mix well, and obtain template emulsion;

[0043] S2. Silicon source hydrolysis polymerization and template removal: Add tetraethyl orthosilicate solution (mixed solution of 2.5mL orthosilicate ethyl ester + 8mL dilute hydrochloric acid) dropwise to the template emulsion obtained in step S1, heat to 50°C, and stir for 3 h, after the reaction is complete, wash and filter out the solid product with absolute ethanol to obtain hollow silica microspheres loaded with ultraviolet absorbers;

[0044] S3, surface modification: 0.24g 2,4-dihydroxybenzophenone (UV0), 5g potassium carbonate and 0.25g (3-chloropropyl)trimethylsilane were added to ...

Embodiment 2

[0046] Embodiment 2 A kind of ultraviolet shielding agent

[0047] The preparation method of described ultraviolet shielding agent comprises the following steps:

[0048] S1. Formation of micellar template: Take 0.33g of polyacrylic acid (molecular weight: 3000) and 0.2g of ethylhexyl methoxycinnamate, add 50mL of absolute ethanol to ultrasonic vibration, and mix well to obtain a template emulsion;

[0049] S2. Silicon source hydrolysis polymerization and template removal: Add tetraethyl orthosilicate solution (mixed solution of 2.5mL orthosilicate ethyl ester + 8mL dilute hydrochloric acid) dropwise to the template emulsion obtained in step S1, heat to 50°C, and stir for 3 h, after the reaction is complete, wash and filter out the solid product with absolute ethanol to obtain hollow silica microspheres loaded with ultraviolet absorbers;

[0050] S3, surface modification: 0.24g 2,4-dihydroxybenzophenone (UV0), 18g potassium carbonate and 0.25g (3-chloropropyl)trimethylsilane ...

Embodiment 3

[0052] Embodiment 3 A kind of ultraviolet shielding agent

[0053] The preparation method of described ultraviolet shielding agent comprises the following steps:

[0054] S1. Formation of micellar template: Take 0.33g polyacrylic acid (molecular weight 3000), 4.4mL ammonia water (25%) and 0.25g ethylhexyl methoxycinnamate, add 50mL absolute ethanol to ultrasonic vibration, mix well, Get template emulsion;

[0055] S2. Silicon source hydrolysis polymerization and template removal: Add 2.5mL orthosilicate ethyl ester dropwise to the template emulsion obtained in step S1, heat to 70°C, stir and react for 3h, after the reaction is complete, wash with absolute ethanol, and filter out the solid product , to obtain hollow microspheres of silicon dioxide loaded with ultraviolet absorbers;

[0056] S3. Surface modification: Add 0.125g 2,4-dihydroxybenzophenone (UV0), 5g potassium carbonate and 0.125g (3-chloropropyl)trimethylsilane to 50mL n-hexane, and react with magnetic stirring f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com