High-mildew-resistance and water-resistance soybean meal protein adhesive and preparation method thereof

A water-resistant, adhesive technology, applied in protein waste adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of easy mildew and stickiness, improve the anti-mildew performance, and have a wide range of applications. , Improve the effect of easy mildew and poor viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

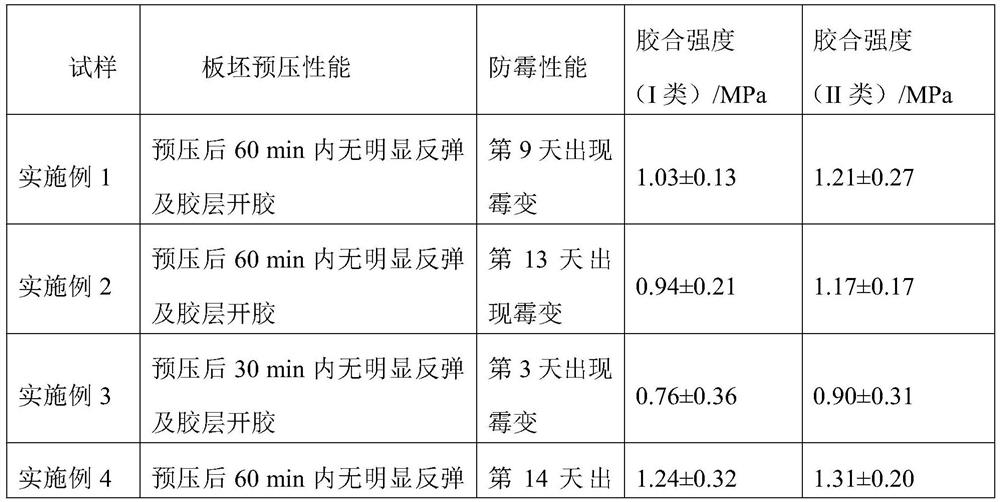

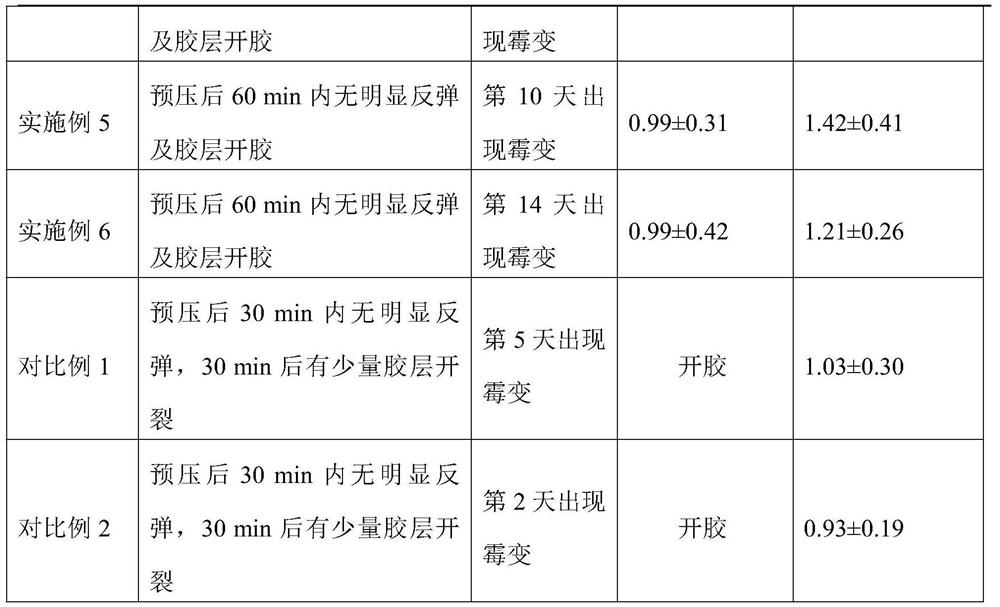

Examples

Embodiment 1

[0023] A highly mildew-proof and water-resistant soybean meal protein adhesive, which is composed of the following components in mass proportion: 40 parts of defatted soybean meal powder, 100 parts of water, 15 parts of cross-linking agent, 2 parts of natural anti-mold agent and 8 parts viscosity modifier.

[0024] The defatted soybean meal powder of this embodiment is obtained by mixing one or more of soybean protein isolate powder, soybean concentrated protein powder, high-temperature defatted soybean meal powder, low-temperature defatted soybean meal powder, and physical defatted soybean meal powder. The particle size of the defatted soybean meal powder is 100 mesh.

[0025] The crosslinking agent of the present embodiment adopts polyamide epichlorohydrin resin, but is not limited to polyamide epichlorohydrin resin, can also adopt cyanate ester, acrylic resin, epoxy resin, polyethyleneimine, diethylamine or One or more of polyamide epichlorohydrin resins.

[0026] The nat...

Embodiment 2

[0033] A highly mildew-proof and water-resistant soybean meal protein adhesive, which is composed of the following components in mass proportion: 45 parts of defatted soybean meal powder, 120 parts of water, 18 parts of cross-linking agent, 4 parts of natural anti-mold agent and 4 parts viscosity modifier.

[0034] The defatted soybean meal powder of this embodiment is obtained by mixing one or more of soybean protein isolate powder, soybean concentrated protein powder, high-temperature defatted soybean meal powder, low-temperature defatted soybean meal powder, and physical defatted soybean meal powder. The particle size of the defatted soybean meal powder is 100 mesh.

[0035] The crosslinking agent of the present embodiment adopts polyamide epichlorohydrin resin, but is not limited to polyamide epichlorohydrin resin, can also adopt cyanate ester, acrylic resin, epoxy resin, polyethyleneimine, diethylamine or One or more of polyamide epichlorohydrin resins.

[0036] The nat...

Embodiment 3

[0043] A highly mildew-proof and water-resistant soybean meal protein adhesive, which is composed of the following components in mass proportion: 10 parts of defatted soybean meal powder, 80 parts of water, 1 part of cross-linking agent, 0.2 parts of natural anti-mold agent and 0.5 parts of viscosity modifier.

[0044] The defatted soybean meal powder of this embodiment is obtained by mixing one or more of soybean protein isolate powder, soybean concentrated protein powder, high-temperature defatted soybean meal powder, low-temperature defatted soybean meal powder, and physical defatted soybean meal powder. The particle size of the defatted soybean meal powder is 60 mesh.

[0045] The crosslinking agent of the present embodiment adopts polyamide epichlorohydrin resin, but is not limited to polyamide epichlorohydrin resin, can also adopt cyanate ester, acrylic resin, epoxy resin, polyethyleneimine, diethylamine or One or more of polyamide epichlorohydrin resins.

[0046] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com