Water-soluble degradable biomass hyperbranched citric acid polyester adhesive and application

A technology of citric acid and adhesives, applied in the direction of adhesives, etc., can solve the problems of short storage period, poor water resistance, and organic solvent residual production costs, and achieve the effects of non-toxic, low cost, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of hyperbranched citric acid polyester comprises the following steps:

[0033] Take citric acid (0.3mol; 57.6g) and glycerin (0.9mol; 82.9g) in a three-necked flask, under the protection of nitrogen, stir and heat up to 120°C for 2 hours to prepare a prepolymer, and add a catalyst to the prepolymer 0.286g of p-toluenesulfonic acid (that is, 0.2% of the total weight of glycerol citrate). Connect the three-neck flask containing the prepolymer to a vacuum pump, and conduct vacuum polymerization at 120°C for 2 hours to obtain a hyperbranched citric acid polyester with a hydroxyl end group and a branching degree of 85%. Denoted as hyperbranched citrate polyester 1.

[0034] Take citric acid (0.9mol; 172.8g) and glycerin (0.3mol; 27.6g) in a three-necked flask, under the protection of nitrogen, stir and heat up to 120°C for 2 hours to prepare a prepolymer, and add a catalyst to the prepolymer 0.4g p-toluenesulfonic acid (that is, 0.2% of the total weight of ...

Embodiment 2

[0036] The preparation of hyperbranched citric acid polyester adhesive comprises the following steps:

[0037](1) Take 40g hyperbranched citric acid polyester 1 and put it into a three-necked flask. Weigh 10 g of borax and dissolve it in 50 mL of distilled water at 80 °C. After the borax is completely dissolved, slowly add all the borax solution into the heated hyperbranched citric acid polyester, and continue to react for 1 h after all the borax is added.

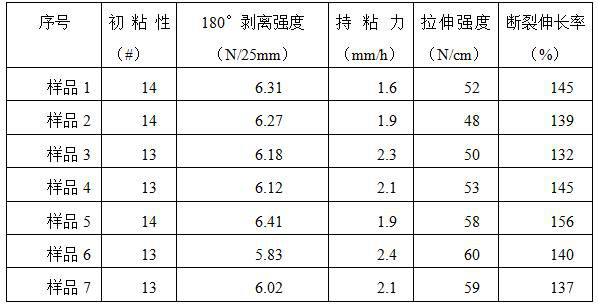

[0038] (2) Part of the water was removed by rotary evaporation to obtain a hyperbranched citric acid polyester adhesive containing boric acid groups with a water content of 21.4 wt%, which was designated as sample 1.

Embodiment 3

[0040] (1) Take 40g hyperbranched citric acid polyester 1 and put it into a three-necked flask. Weigh 15g of borax and dissolve it in 75mL of distilled water at 80°C. After the borax is completely dissolved, slowly add all the borax solution into the heated hyperbranched citric acid polyester, and continue to react for 1 h after all the borax is added.

[0041] (2) Part of the water was removed by rotary evaporation to obtain a hyperbranched citric acid polyester adhesive containing boric acid groups with a water content of 24 wt%, which was designated as sample 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com