Remote greenhouse vegetable lighting equipment based on Internet of Things

A technology of lighting equipment and the Internet of Things, applied in the field of the Internet of Things, can solve the problems of dust cover of the supplementary light, many supplementary light settings, and reduced illumination area, so as to reduce labor intensity, increase the illumination area, and reduce layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

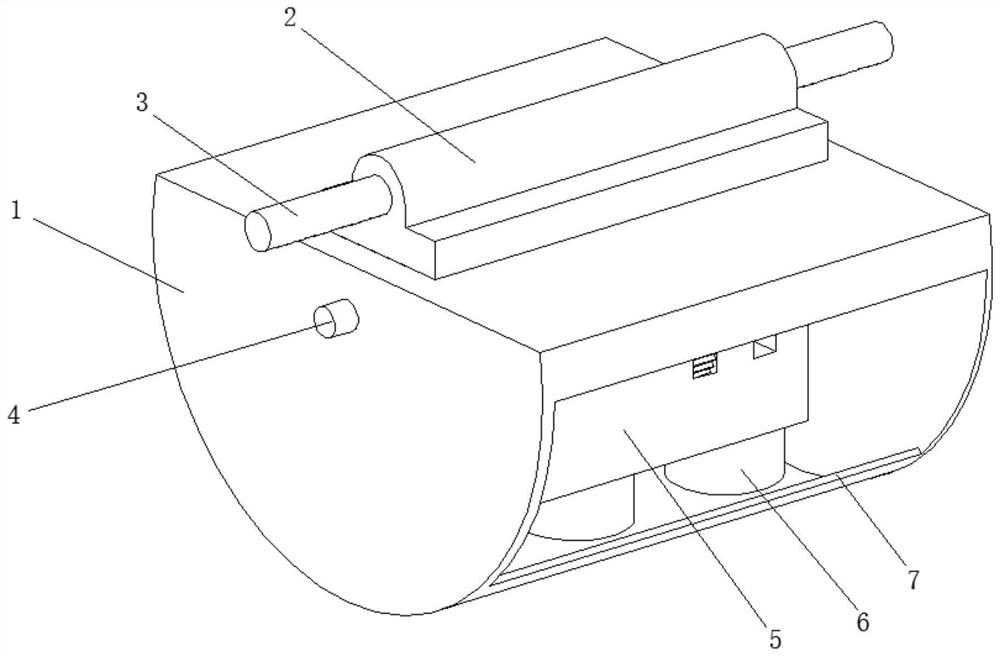

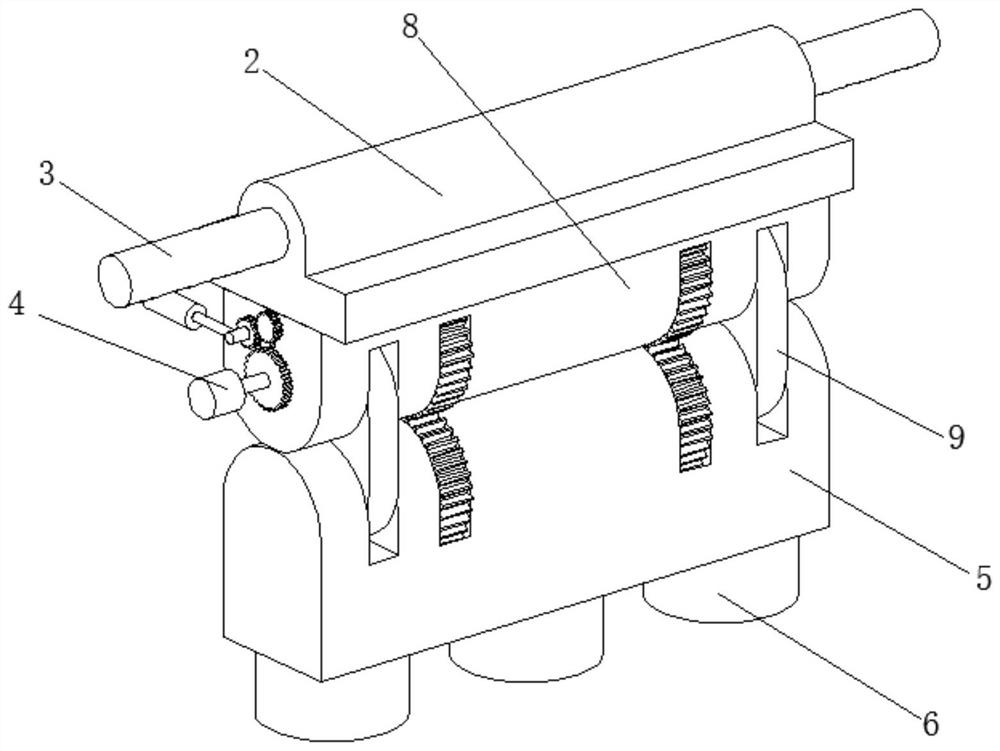

[0030] A remote greenhouse vegetable lighting device based on the Internet of Things, such as Figure 1-Figure 5 As shown, it includes a housing 1, the top of the housing 1 is welded with a mounting block 2, the inner wall of the mounting block 2 is slidably connected with a fixed rod 3, the front of the housing 1 is provided with a transmission mechanism 4, and the inner wall of the housing 1 is welded with a cleaning plate 7, The bottom of the mounting block 2 is welded with an upper fixed plate 8, and the inwall of the upper fixed plate 8 is rotatably connected with two connecting plates 9, and the surface of the connecting plate 9 is rotatably connected with a lower fixed plate 5, and the bottom of the lower fixed plate 5 is connected by three A fill light 6.

[0031] In this embodiment, the surface of the upper fixing plate 8 is welded and fixed to the inner wall of the top of the housing 1, and there are two cleaning plates 7, and the two cleaning plates 7 are symmetrica...

Embodiment 2

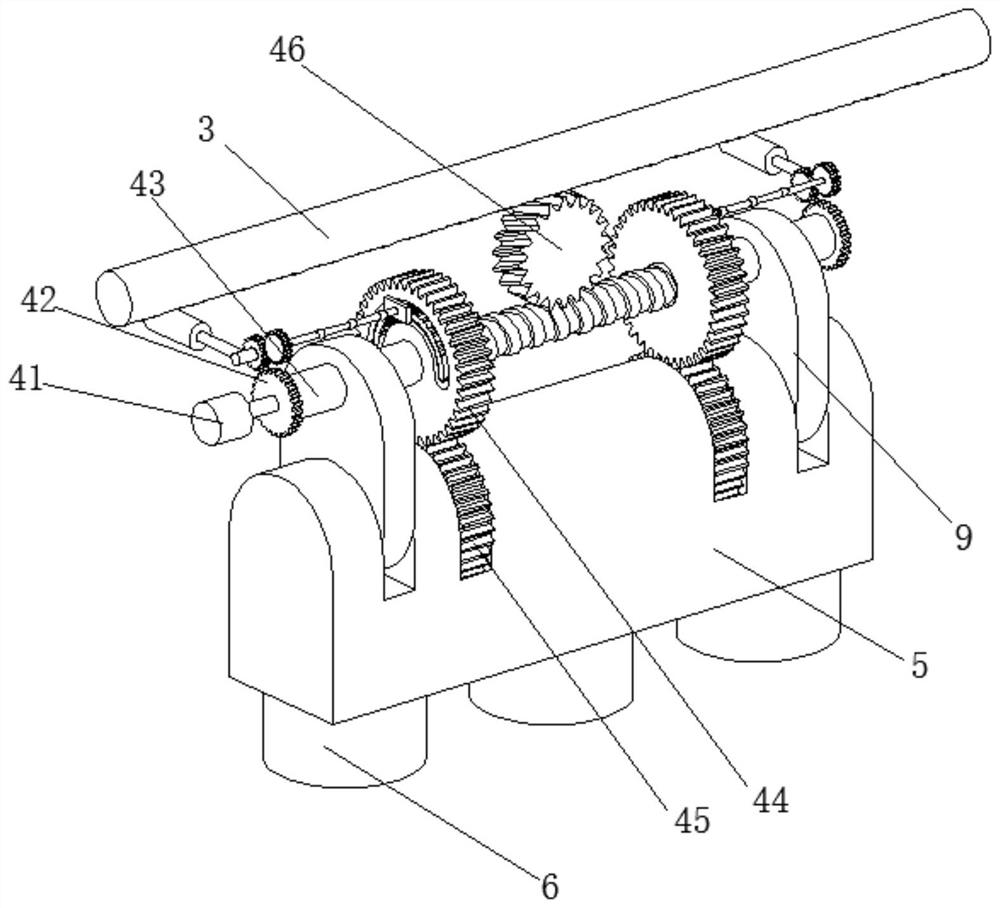

[0042] like Figure 5-Figure 7 As shown, on the basis of Embodiment 1, in this embodiment, the surface of the electric push rod 421 is connected to the inner wall of the housing 1 by bolts, and the axis of the pinion 424 is rotationally connected with the front part of the upper fixing plate 8. The shaft center of the gear 425 is clamped and fixed with the output end of the motor 41 .

[0043] When the electric push rod 421 is retracted, the transmission gear 423, the large gear 425 and the small gear 424 are not meshed, the motor 41 will only drive the device to move, and will not drive the fill light 6 to rotate and clean, which can realize the separation operation and is practical The stability is greatly increased; when moving, the lower fixed plate 5 does not need to rotate all the time, which reduces the frequency of use of each gear, thereby reducing the loss between each gear and increasing the service life.

[0044] It is worth noting that the rotating device 44 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com