Method for determining reasonable stopping line position based on stress field and vibration wave field

A technology of shock wave and stop production line, which is applied in the field of determining the position of reasonable stop production line in deep working face based on stress field and shock wave field, can solve the problems that the position of stop production line in deep working face cannot be effectively and reasonably determined, and achieve The effect of reliable evaluation grading results, detailed evaluation results, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

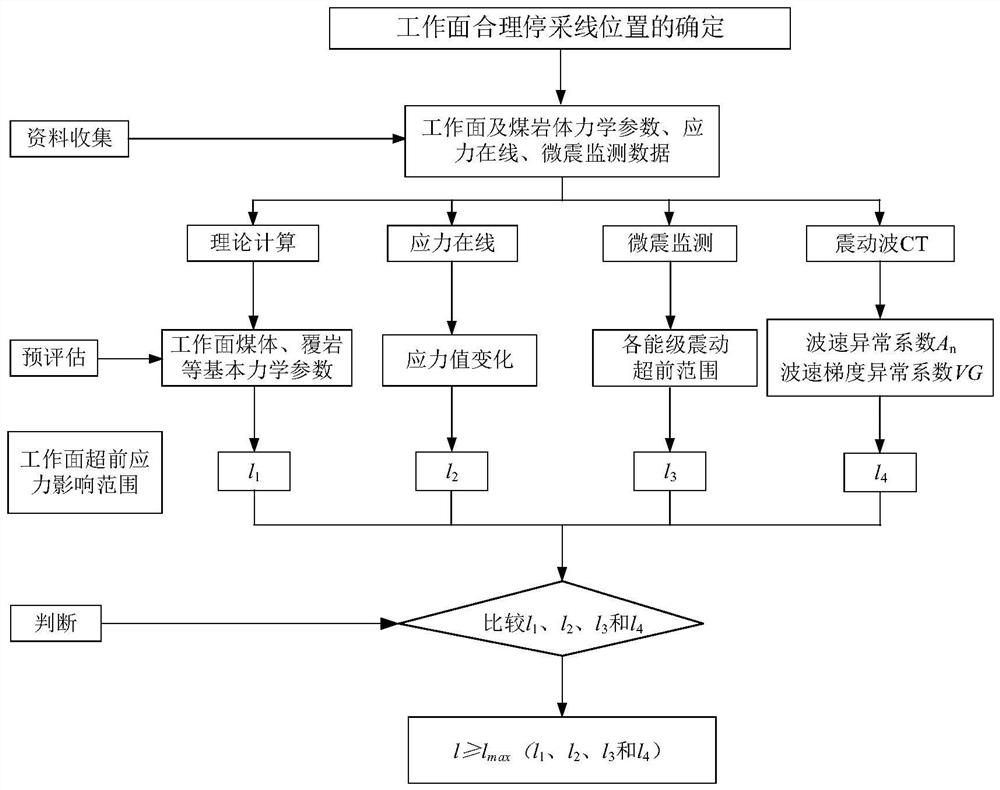

[0044] Such as figure 1 As shown in , a method for determining the location of a reasonable shutdown line based on the stress field and the shock wave field includes the following steps:

[0045] Step 1, collect the relevant geological information of the working face to determine the reasonable stop production line position;

[0046] Relevant geological information includes: basic physical and mechanical properties of coal strata, mine mining and working face layout data. Ratio, internal friction angle of coal-rock layer, tensile strength of coal-rock layer, breaking expansion coefficient of overlying rock, body force of overlying rock and uniaxial compressive strength of overlying rock;

[0047] The mine mining and working face layout data include: the buried depth of the working face and the length of the working face.

[0048] Step 2, determine the first influence range of the advanced stress distribution of the working face according to the relevant geological informatio...

Embodiment 2

[0099] In the 3302 working face of a certain mine, the risk of rock burst near the stop line is high during the mining process. The method for determining the position of the reasonable stop line based on the "stress field-vibration wave field" in the present invention will be used to analyze the working face mining process. The position of production line in stoppage is dynamically adjusted, and the specific implementation steps are as follows:

[0100] Step 1, collect geological information related to the working face as shown in Table 3

[0101] The 3302 working face is located in the east of the third mining area in the west wing of Xingcun Coal Mine, with an average ground elevation of 55m, an average underground elevation of 1200m, and a mining depth of about 1250m. The 350m to the southwest of the working face is the goaf of the 3308 working face, the three mining areas in the northwest are three centralized uphills, and the northeast is the three development alleys in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com