Quick wiring device for multi-core cable and operation method

A wiring device, multi-core cable technology, applied in the direction of conductive connection, contact assembly/disassembly, circuit, etc., can solve the problems of substandard cable wiring quality, threatening system operation safety, etc., to improve automatic control and automatic configuration, The effect of improving stability and improving wiring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

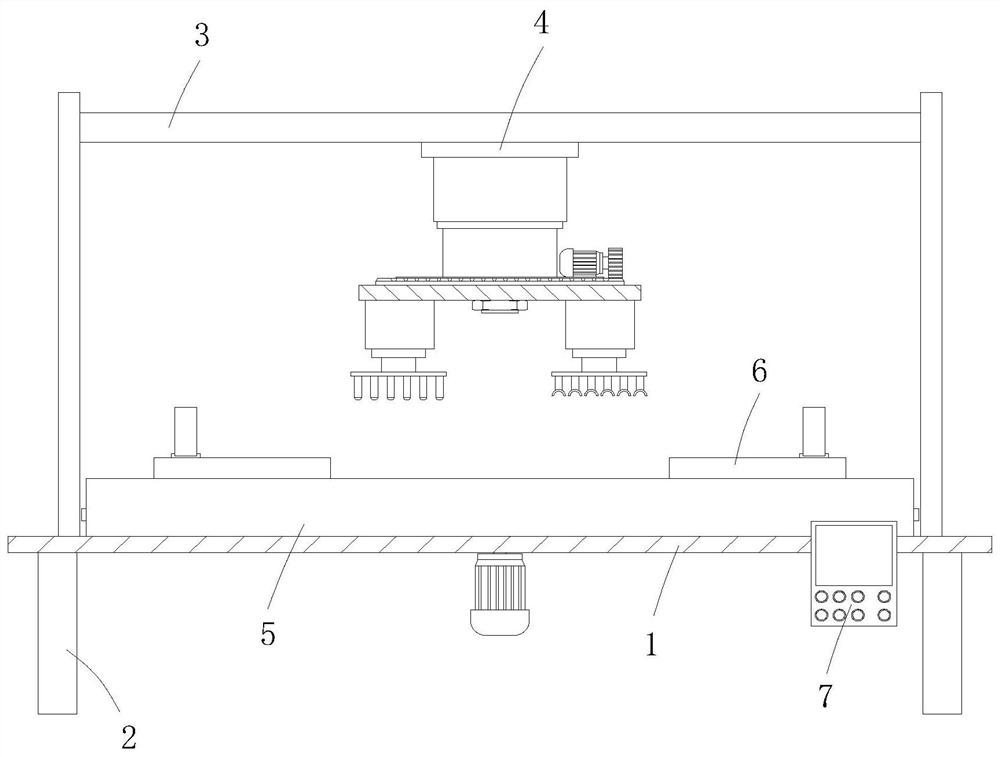

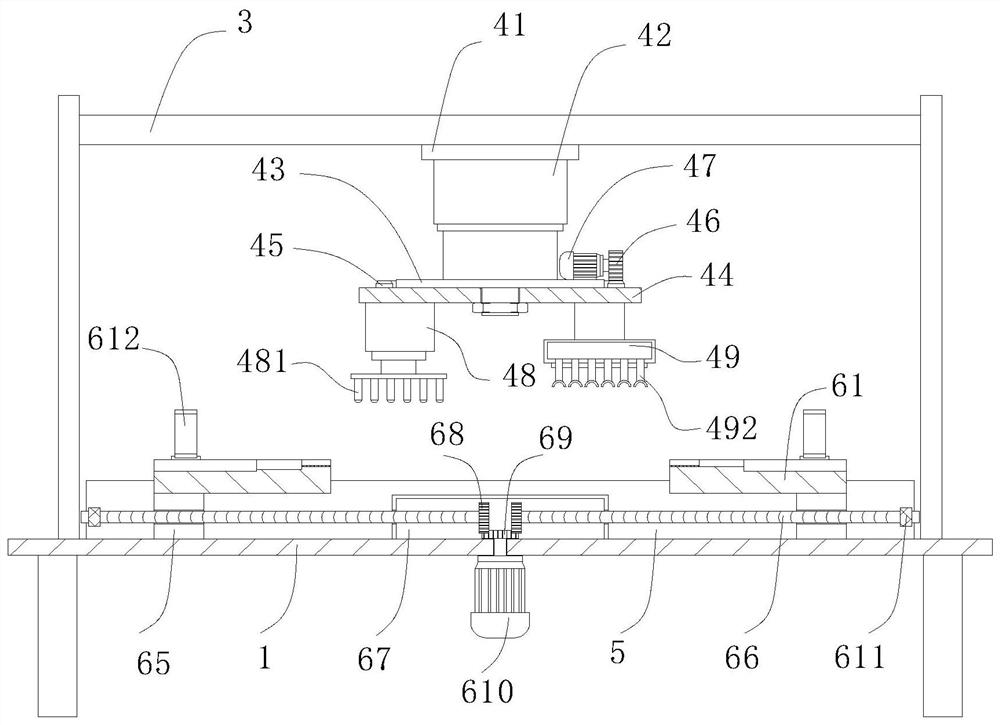

[0041] A quick wiring device for multi-core cables, comprising a workbench 1 and a plurality of support feet 2 installed on the lower edge of the workbench 1, an inverted U-shaped frame 3 is installed on the upper end of the workbench 1, and the frame 3 The wiring mechanism 4 is installed on the inner top wall, which is used to weld the wire core a2 and the insulation protection outside the wire core a2 for the two cables a1 that have been paired. A wire alignment mechanism 6 for docking the inner multi-strand wire core a2;

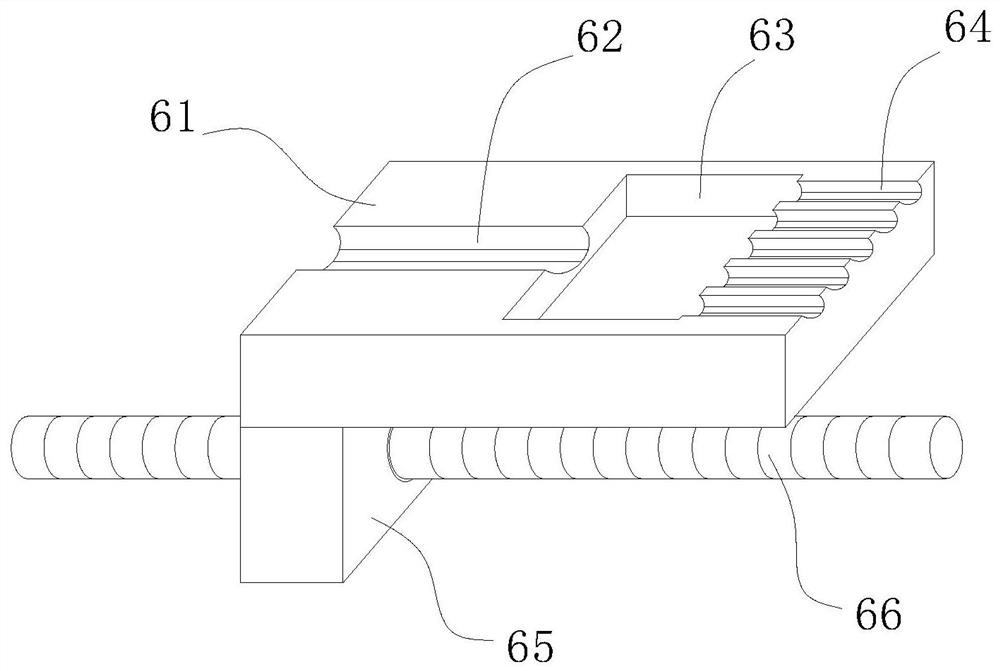

[0042] In this example, if Figure 2-4 As shown, the alignment mechanism 6 includes two sliding seats 65 symmetrically slidably installed on the upper end of the workbench 1, and the upper end of the sliding seat 65 is horizontally equipped with an alignment seat 61, and the opposite sides of the two alignment seats 61 are The upper end is provided with a wire groove 62 for placing the cable a1, and the opposite sides of the two wire grooves 62 are seque...

Embodiment 2

[0053] The present invention also provides an operation method based on the quick wiring device for multi-core cables, the specific steps of the operation method are:

[0054] S1. Place the two cables a1 from both sides in the wire slot 62 of the wire holder 61, strip off the insulation layer at the end, separate the multi-strand wire core a2, and insert it on one of the cables a1 first. The outer insulating rubber sleeve a4 is inserted into the wire core rubber sleeve a3 on the separated multi-strand wire core a2 respectively, and the multi-strand wire core a2 is placed in the branching groove 64 in sequence, and the cable a1 position;

[0055] S2. Start the servo motor 610, the driving bevel gear 69 meshes with the two driven bevel gears 68, cooperate with the rotation of the screw mandrel 66, the two alignment seats 61 are close to each other and fit together, and the multi-strand wire cores of the two cables a1 a2 are respectively aligned through the distribution slot 64;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com