Rotor assembly and winding process thereof

A technology of rotor windings and components, which is applied in the direction of electric components, windings, electrical components, etc., and can solve problems such as broken rotor windings, paint wear, and short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

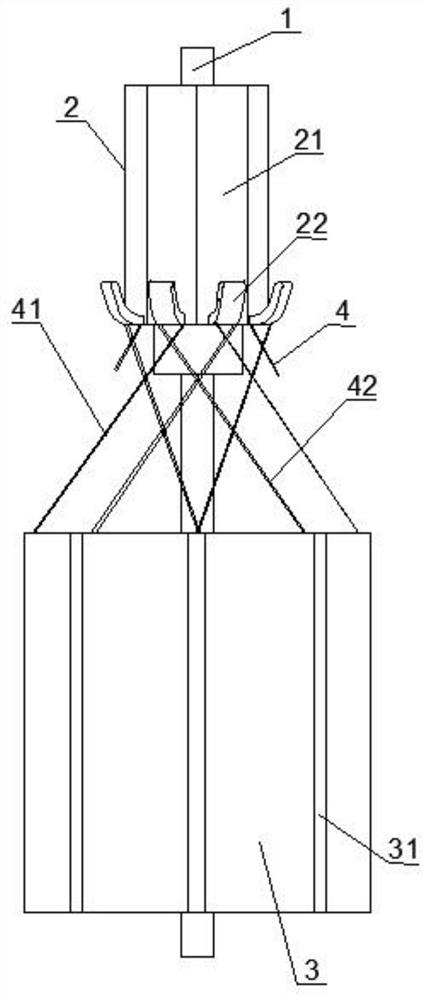

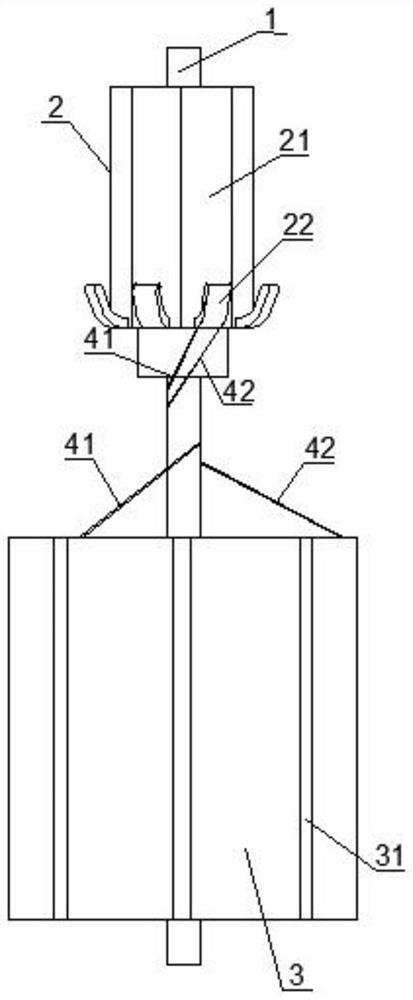

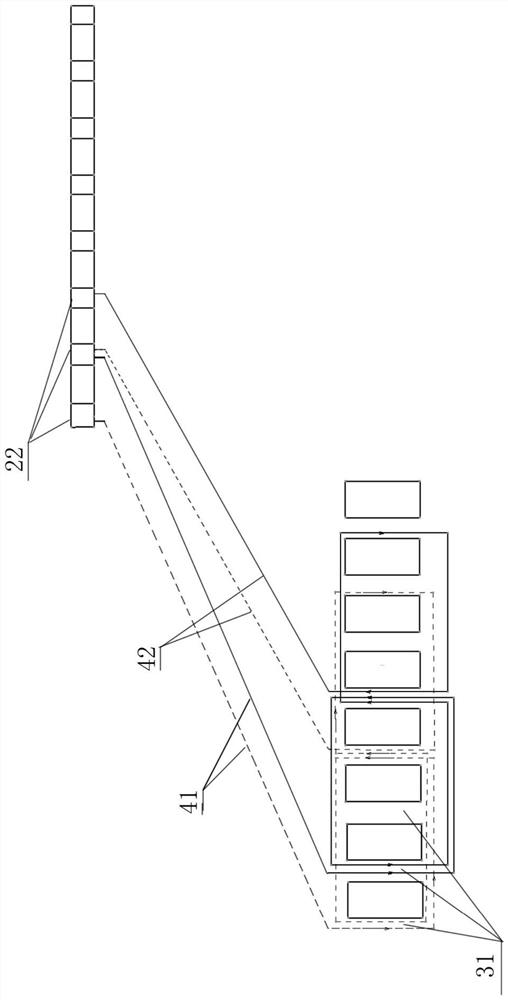

[0032] figure 1 It is a structural schematic diagram of an existing rotor assembly, including a rotating shaft 1 , a commutator 2 and an iron core 3 arranged on the rotating shaft 1 . The rotor winding 4 is directly wound between the commutator 2 and the iron core 3 . The rotor winding 4 includes an outgoing wire 41 drawn from the commutator 2 to the iron core 3 and a return wire 42 drawn from the iron core 3 to the commutator 2 . It can be seen from the figure that the rotor winding 4 has a large number of intersections in the suspension. Since the outlet wire 41 and the return wire 42 do not have any support at the intersection, the tension of the rotor winding 4 cannot be released, so the high-speed vibration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com