Accessory module, preparation method thereof and prefabricated accessory template

A technology of accessories and modules, which is applied in the field of orthodontics, can solve problems such as the inconsistency between the shape of the accessories and the designed shape, erosion of the tooth area, cavitation in the storage tank, etc., to solve the problem of instability, the matching position is correct, and the setting position can be adjusted. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention also provides a method for preparing the above accessory module, comprising the following steps:

[0065] Get the digital data model of the attachment;

[0066] generating an accessory model based on the digital data model of the accessory;

[0067] pressing the main body with the accommodating cavity on the diaphragm according to the accessory model by using hot pressing technology;

[0068] filling the accessory in the accommodating cavity;

[0069] fixing the spacer on the surface of the accommodating cavity;

[0070] The retainer is fixed on the side of the body away from the teeth and is located around the accommodating cavity.

[0071] Specifically, the attachment is a prefabricated solid attachment or an attachment to be cured.

[0072] In some embodiments, before covering the surface of the accommodating cavity, the isolator further includes a step of: disposing an acid etching layer on the surface of the accommodating cavity.

[0073]...

Embodiment 1

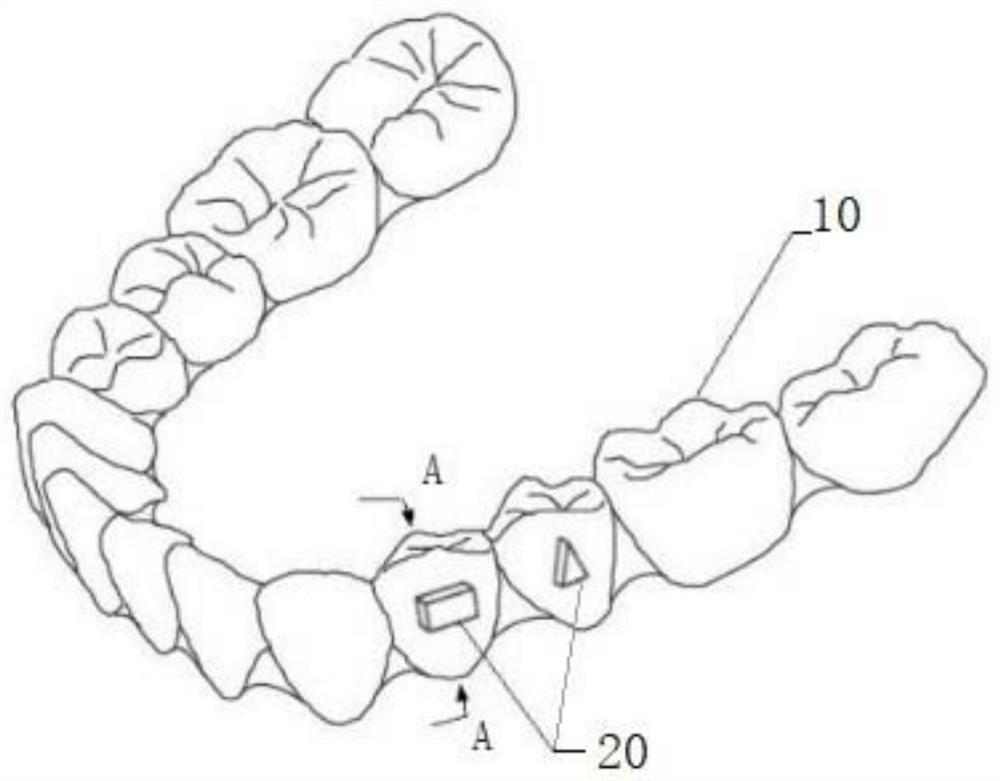

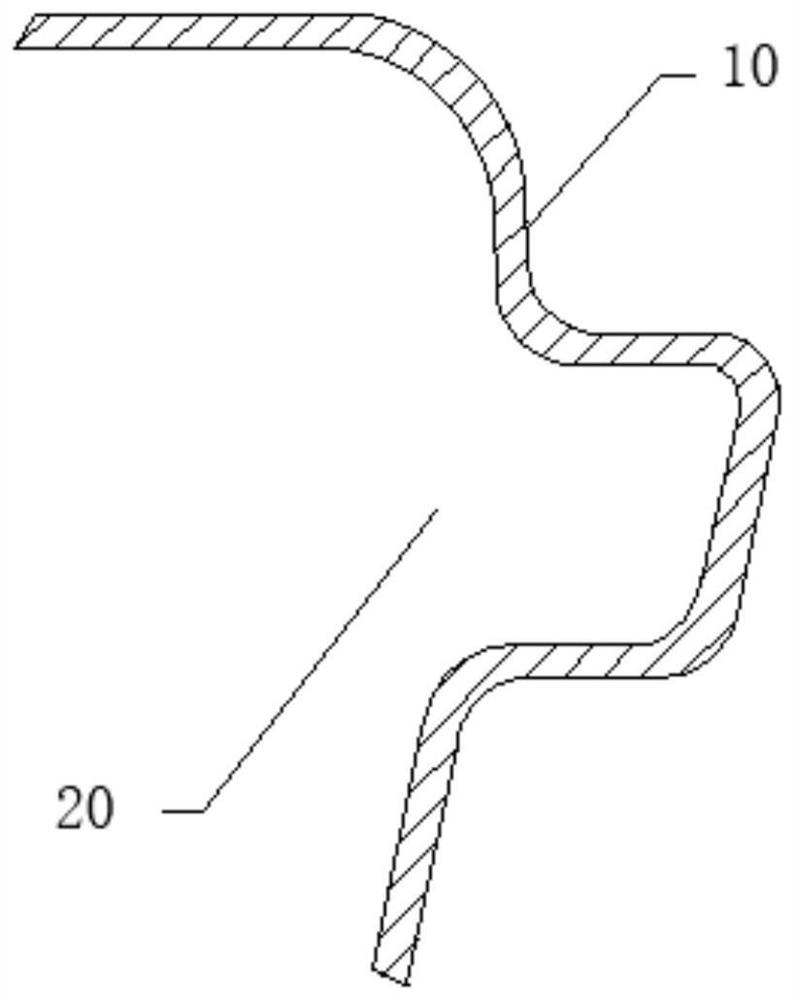

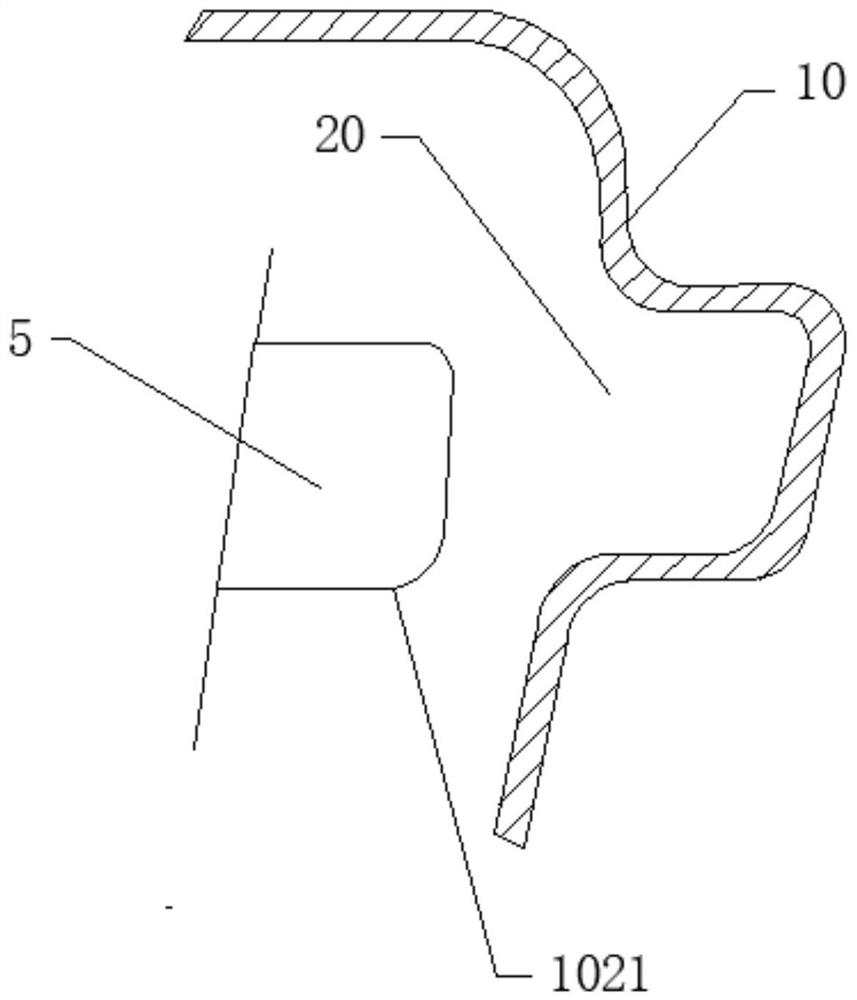

[0079] See image 3 with Figure 4 , the accessory module provided in this embodiment includes a main body 1, an accessory 5, an isolation layer 4 and an adhesive layer 7, the main body 1 is made in one piece, and it has an accommodating cavity 1021, and the accessory 5 is arranged in the accommodating cavity In 1021 , the isolation layer 4 covers the accommodating cavity 1021 and isolates the accessory 5 in the accommodating cavity 1021 ; an adhesive layer 2 and an acid etching layer 3 are also provided between the isolation layer 4 and the accessory 5 . The accommodating cavity 1021 is provided with an auxiliary retaining portion 11 in the circumferential direction, and the adhesive layer 7 is disposed on a side of the auxiliary retaining portion 11 opposite to the isolation layer 4 .

[0080] In this embodiment, the adhesive layer 2 is an adsorption film that has absorbed an adhesive, and the acid etching layer 3 is an adsorption film that has absorbed an etchant, and an i...

Embodiment 2

[0085] See image 3 with Figure 5 As shown, the difference between the accessory module of this embodiment and the first embodiment is that a barrier layer 6 is also provided between the acid etching layer 3 and the adhesive layer 2, and a barrier layer 6 is also provided between the adhesive layer 2 and the accessory 5. Insulation layer8.

[0086] In this embodiment, the acid etching layer is formed by filling, coating or spraying with an etching agent. The adhesive layer is formed by filling, coating or spraying with adhesive. Due to the fluidity of the etching layer and the bonding layer, it is necessary to provide a layer structure (barrier layer, insulating layer, etc.) for isolation between the etching layer and the bonding layer, and between the bonding layer and the attachment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com