Preparation method for controllable and even silver nanowire electric conduction fibroin fiber bundle

A technology of silver nanowires and silk fibers, which is applied in fiber processing, animal fibers, silk reeling, etc., can solve the problems of poor durability and electrical conductivity, and cannot be directly implanted into the body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

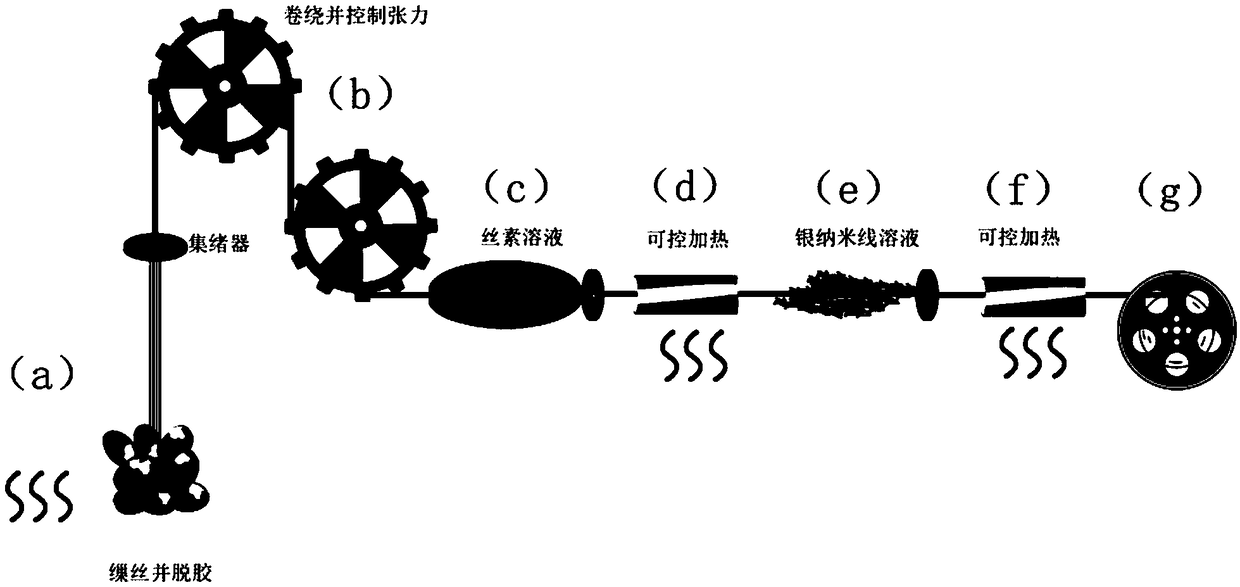

[0034] see figure 1 , figure 1 It is a schematic diagram of the steps of the preparation method of the controllable and uniform silver nanowire conductive silk fiber bundle of the present invention. Such as figure 1 As shown, the present invention provides a kind of preparation method of controllable uniform silver nanowire conductive silk fiber bundle, comprising the following steps:

[0035] Step 1: reeling out multiple fibers from the silkworm cocoon, and fully degumming to obtain multiple glue-free fibers;

[0036] In one embodiment, this step can be specifically performed as follows: 1-10 fibers are reeled from silkworm cocoons, and fully degummed to obtain glue-free fibers, wherein the degumming method is to add silkworm cocoons to 0.5-1% sodium carbonate solution, Heat to 100°C, boil for 45-60 minutes, then take it out, wash it in deionized water for several times, and repeat the operation again.

[0037] Step 2: passing the plurality of glue-free fibers through the...

Embodiment 1

[0063] This implementation case shows a method for preparing a controllable and uniform silver nanowire conductive silk fiber bundle according to the following steps:

[0064] Step 1: Reel 2 fibers from silkworm cocoons, add silkworm cocoons to 0.5% sodium carbonate solution, heat to 100°C, boil for 45min, then take out and wash in deionized water several times. Repeat the operation one more time.

[0065] Step 2: Merge into a fiber bundle through the thread collector, wind it through the winding device, and control the tension of the fiber at 1cN to ensure the tension state of the fiber bundle.

[0066] Step 3: Pass 15wt% fiber bundles through a silk fibroin solution bath so that the surface of the fibers is coated with silk fibroin solution, and use a collector with a central hole diameter of 15um and a roundness tolerance of 0.1um to control the amount of silk fibroin coating.

[0067] The silk fibroin solution is prepared using common methods:

[0068] The silk fibroin s...

Embodiment 2

[0082] Step 1: Reel 6 fibers from silkworm cocoons, add silkworm cocoons to 0.8% sodium carbonate solution, heat to 100°C, boil for 50 minutes, then take them out and wash them in deionized water several times. Repeat the operation one more time.

[0083] Step 2: Merge into a fiber bundle through the thread collector, wind it through the winding device, and control the tension of the fiber at 5cN to ensure the tension state of the fiber bundle.

[0084] Step 3: passing the fiber bundle through a 20wt% silk fibroin solution bath, so that the fiber surface is wrapped with the silk fibroin solution. Use a thread collector with a middle hole of 50um and a roundness tolerance of 0.1um to control the amount of silk fibroin coating.

[0085] The silk fibroin solution is prepared using common methods:

[0086] The silk fibroin solution is prepared by degumming, dissolving, dialysis and other processes, using lithium bromide (9.3M) solution system.

[0087] (1) Degumming process

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com