Fire prevention automatic sprinkler system with adjustable temperature

A technology of automatic spraying and temperature control, applied in fire rescue and other directions, can solve the problems of not being able to meet the needs of stirring and extinguishing fire, lack of fire extinguishing agent and fire-fighting foam, and lack of foaming mechanism, so as to meet the needs of fire safety maintenance, The effect of improving the efficiency of fire fighting and reducing the frequency of cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

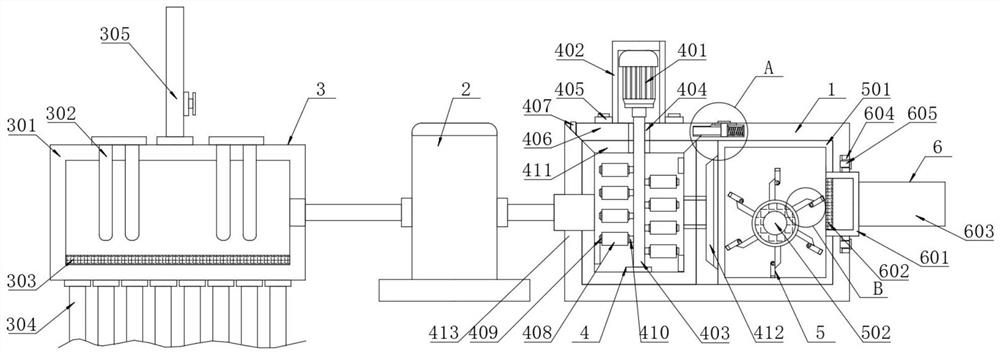

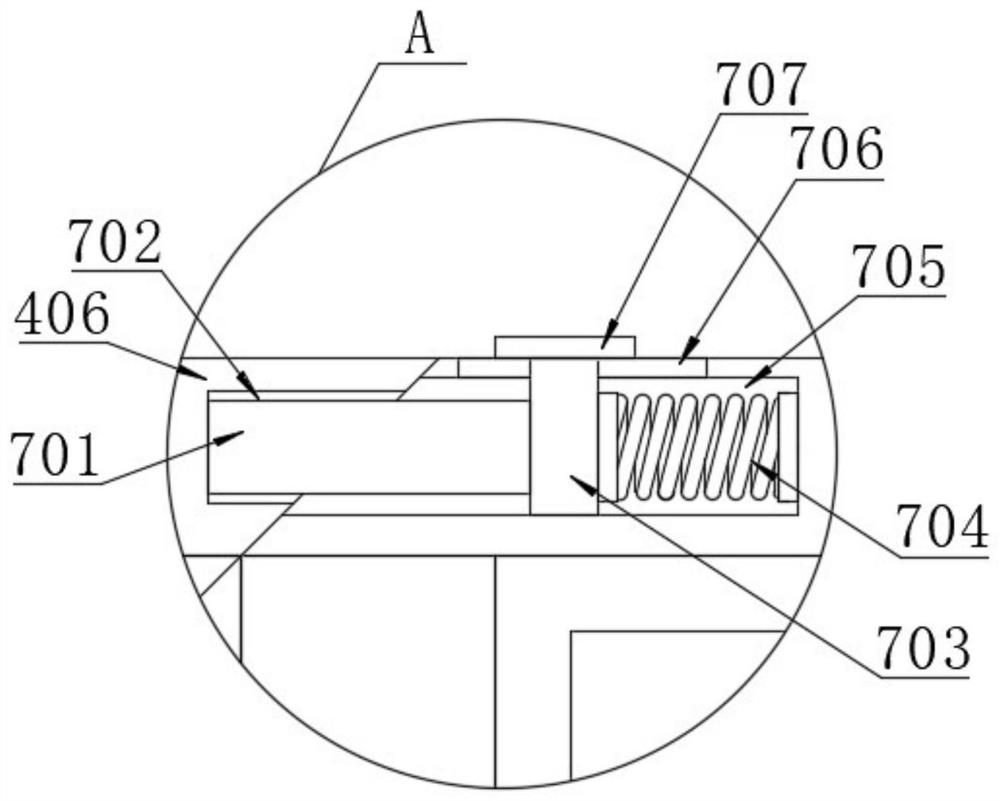

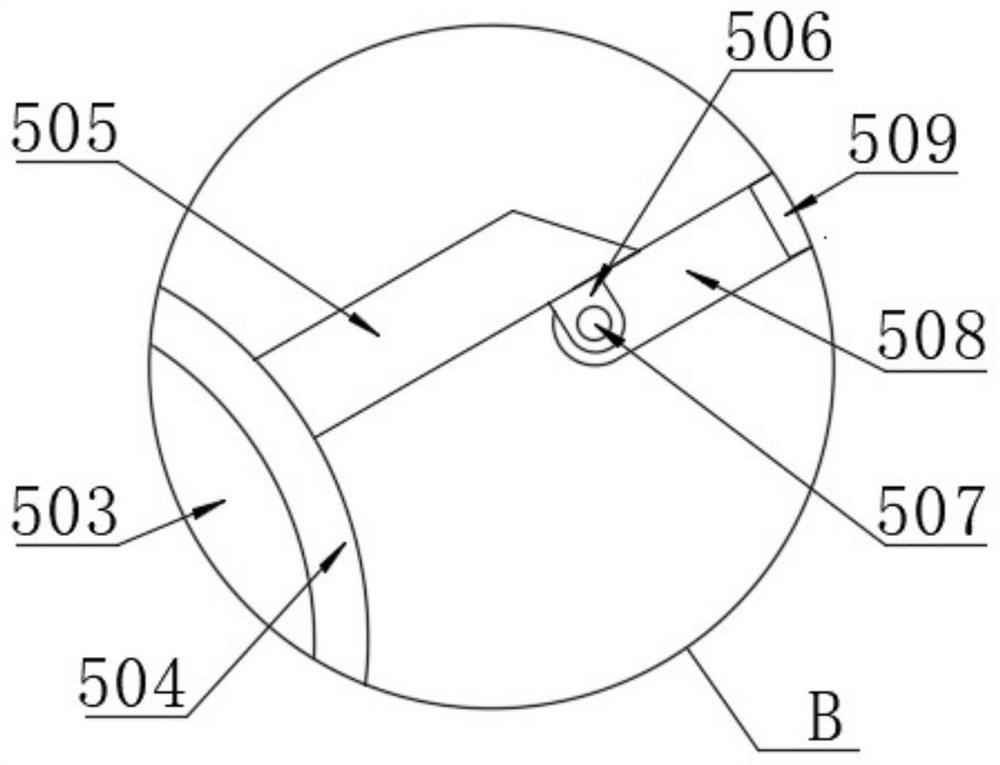

[0045] The specific embodiment is: when the first rotating shaft 403 rotates to drive the stirring rod 410 and the stirring blade 408 to rotate, the stirring blade 408 can rotate outside the stirring rod 410 through the one side bushing 409, and then can rotate through the offset of the stirring blade 408, Improve the mixing effect, and the shaft sleeve 409 can be separated from the stirring rod 410, which is convenient for replacing and maintaining the damaged stirring blade 408. At the same time, the positioning column 407 on the top of the cover plate 406 can conveniently and quickly snap the cover plate 406 into the top of the box body 1, At the same time, the motor 401 can be protected and limited by the external protective shell 402 to avoid external collision damage and effectively improve the fire prevention capability, and the protective shell 402 can be fixed and installed through the fixing blocks 405 on both sides, which is convenient for disassembly and maintenance,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com