Ultrasonic cleaning device, semiconductor equipment and control method of semiconductor equipment

A technology of cleaning device and control method, which is applied in semiconductor/solid-state device manufacturing, cleaning methods and utensils, cleaning methods using liquids, etc. problem, to avoid the effect of uneven cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS It should be understood that the specific embodiments described herein are intended to illustrate and explain the present invention and is not intended to limit the invention.

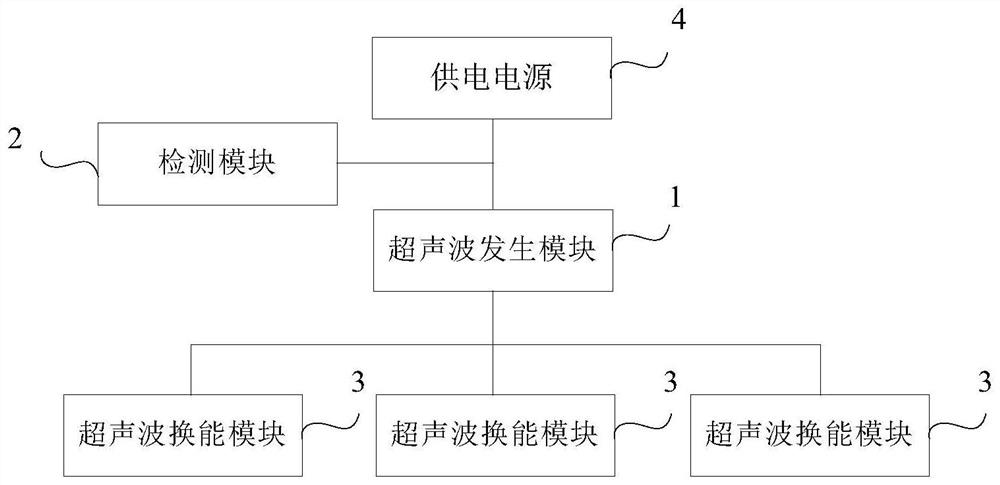

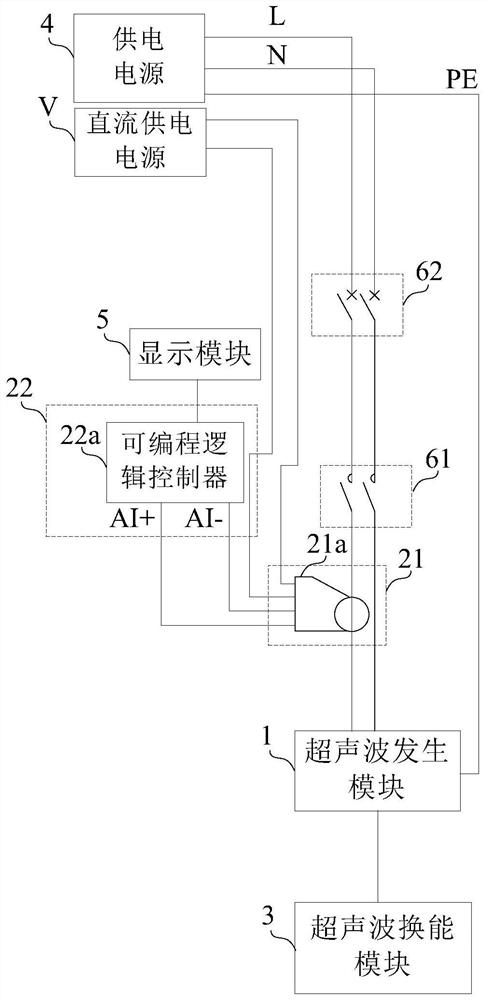

[0035]The embodiment of the present invention provides an ultrasonic cleaning device, which is applied to a semiconductor device.figure 1 A module schematic diagram of an ultrasonic cleaning device provided by an embodiment of the present invention, such asfigure 1 As shown, the ultrasonic cleaning device includes: an ultrasonic wave generating module 1, a detection module 2, and a plurality of parallel ultrasonic transduction modules 3. The ultrasonic occurrence module 1 is connected to the power supply 4 and the plurality of ultrasonic transduction modules 3, and the ultrasonic occurrence module 1 is used to provide a drive signal to each of the ultrasonic transduction modules 3. The ultrasonic transduction module 3 is used to emit ultrasonic waves under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com