Pin correction device for metal packaging thick film integrated circuit

A technology for calibrating devices and integrated circuits, which is applied in the field of metal-packaged thick-film integrated circuits, can solve the problems of glass insulator damage, product airtightness failure, product elimination, glass insulator damage, etc., and achieves convenient use and improved airtightness. And the effect of quality reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

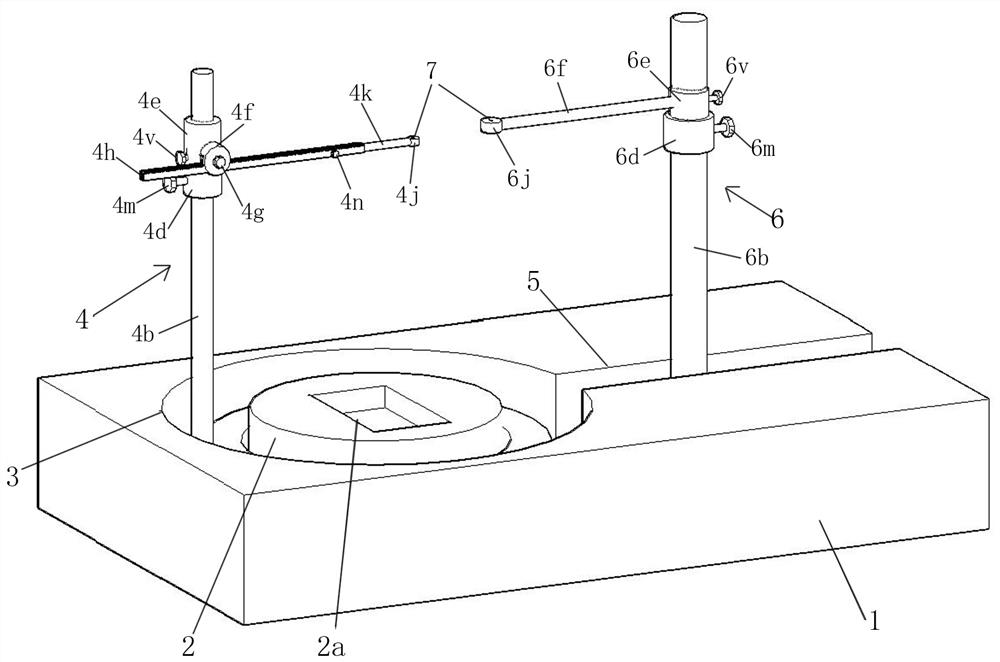

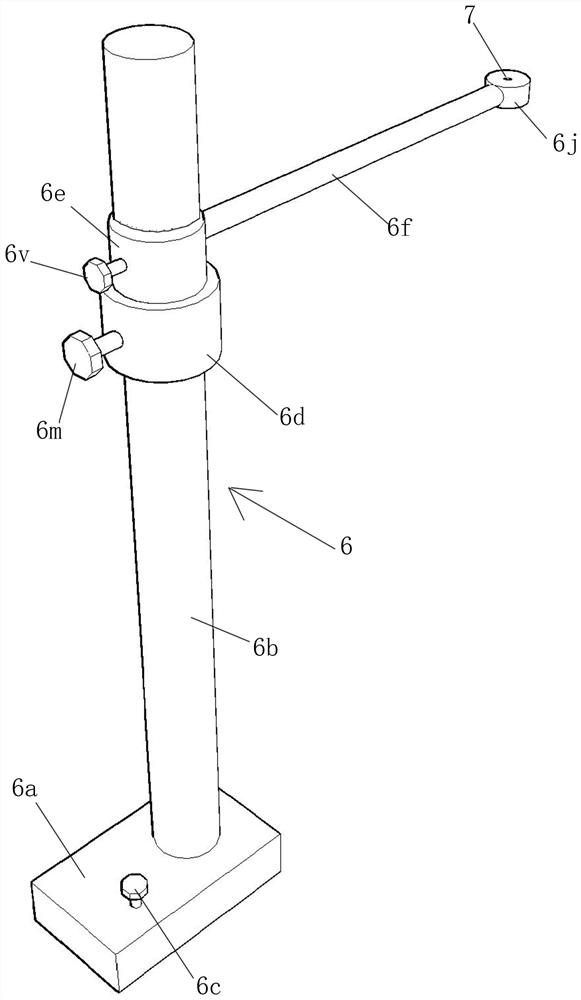

[0020]Such asFigure 1-5As shown, a metal-encapsulated thick film integrated circuit lead correction device includes a rectangular base 1 with a round table 2 at one end of the base 1, and a round table 2 corresponding to the thick film integrated circuit to be corrected. Mating installation slot 2a.

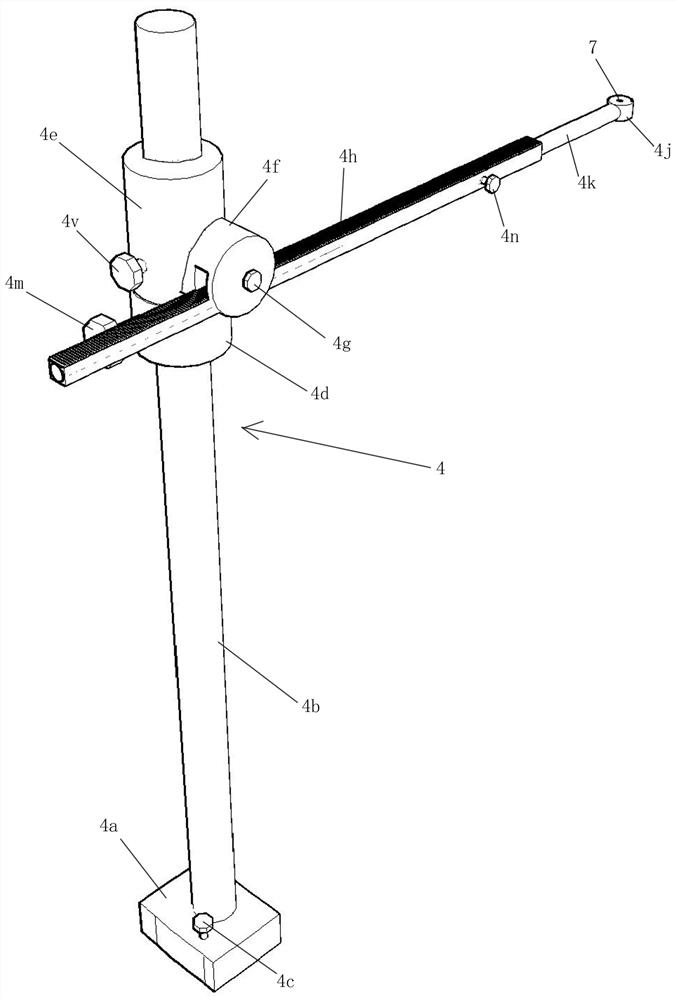

[0021]A ring groove 3 is also provided on the base 1 outside the round table 2, and a first correction device 4 with sliding fit is provided in the ring groove 3. The illustrated first correction device 4 includes a corresponding mating sliding block 4a provided in the ring groove 3. Vertically distributed uprights 4b are connected to the sliding block 4a, and the sliding blocks 4a on both sides of the upright 4b are respectively provided with a locking screw 4c corresponding to the groove bottom of the ring groove 3.

[0022]A first sliding sleeve 4d and a second sliding sleeve 4e are sequentially sleeved on the upright 4b, and correspondingly matched first locking nails 4m and second locki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com