A grinding device for cylindrical wood

A wood and cylinder technology, applied in the direction of grinding drives, grinding machines, grinding slides, etc., can solve problems such as low efficiency, and achieve the effect of improving grinding efficiency and improving refueling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

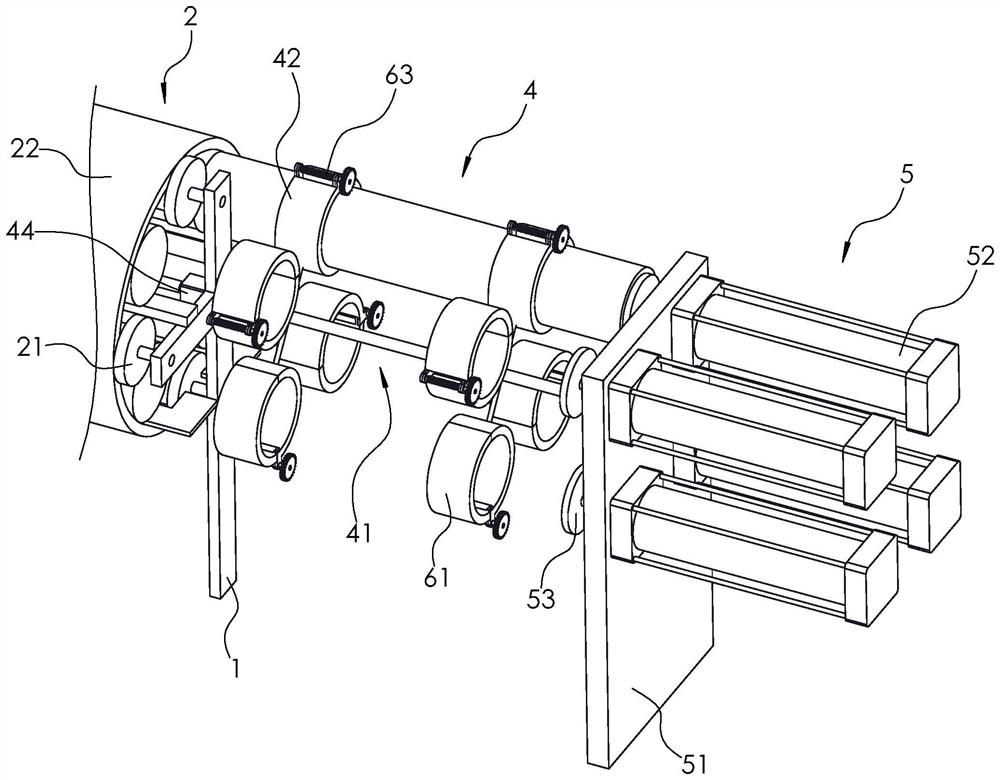

[0034] The following is attached Figure 1-6 The application is described in further detail.

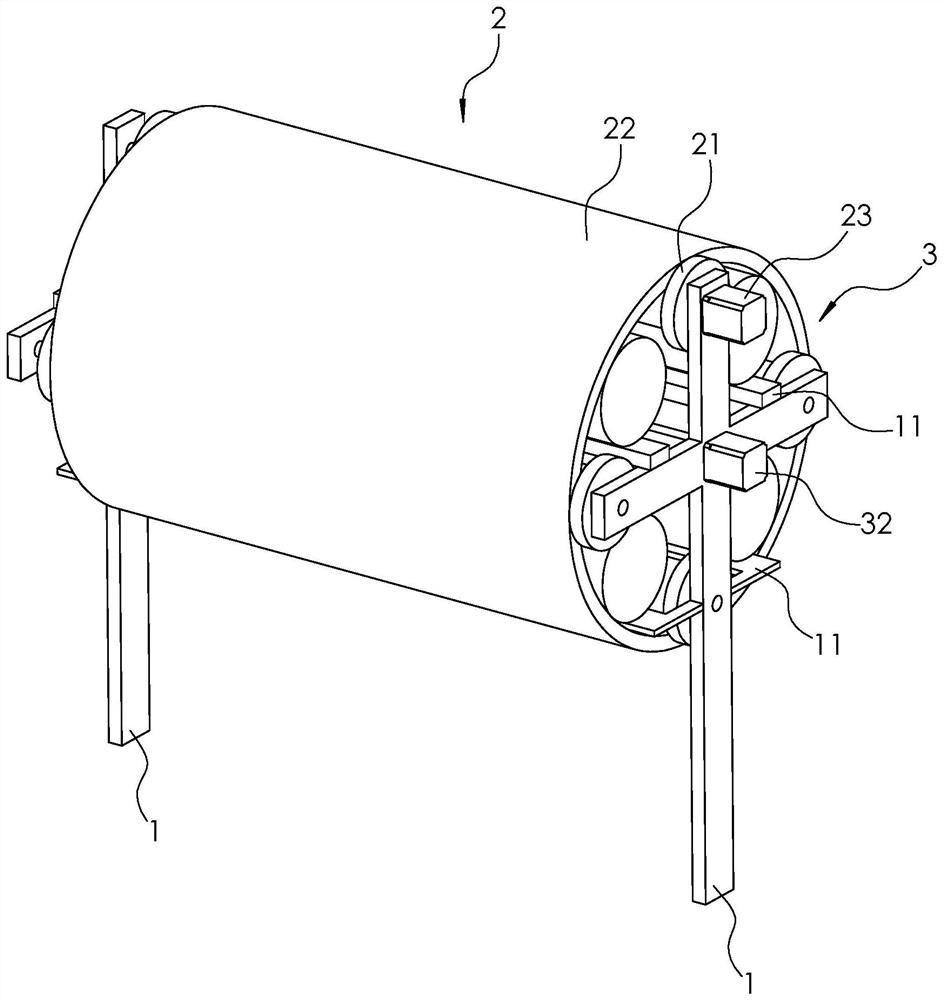

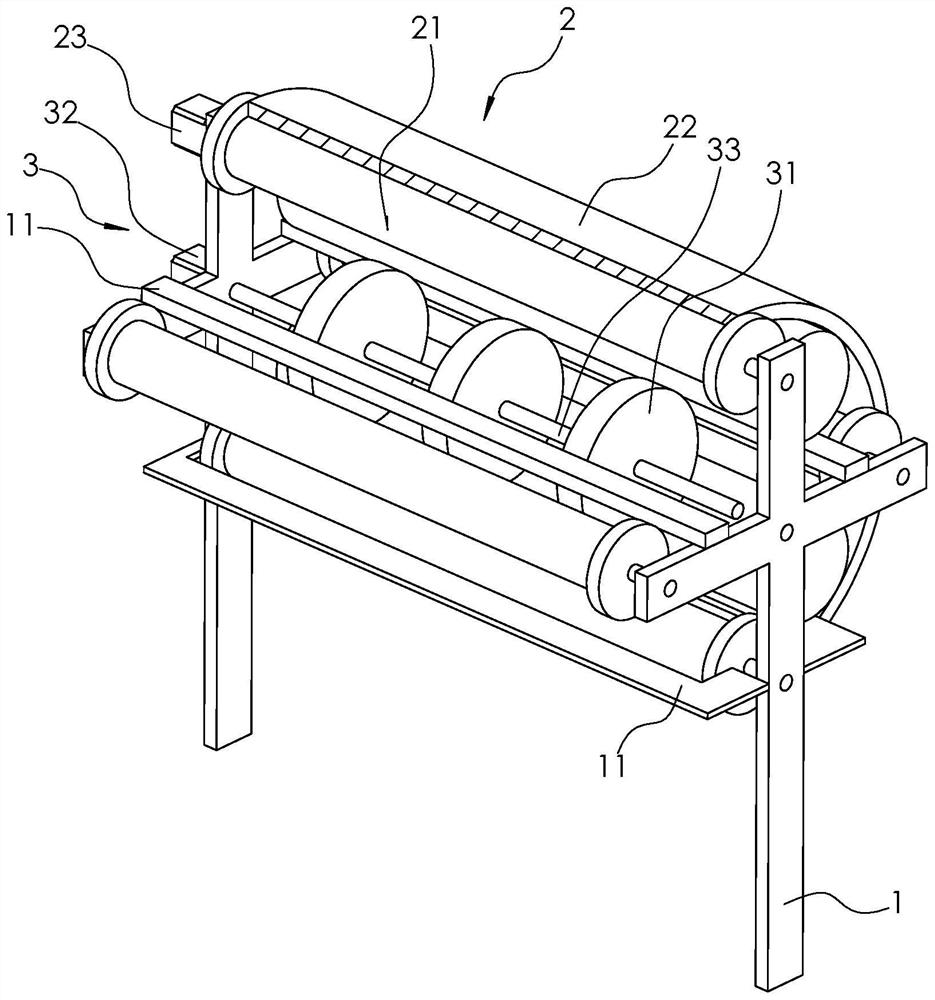

[0035] The embodiment of the present application discloses a grinding device for cylindrical wood. Such as figure 1 As shown, a grinding device for cylindrical wood includes a bracket 1, a grinding mechanism 2 and a pressing mechanism 3. The bracket 1 includes two vertical plates arranged in a cross shape; Boards 11, a cylindrical piece of wood is placed on each pallet 11; in this embodiment, the number of pallets 11 is four.

[0036] Such as figure 1 and figure 2 As shown, the grinding mechanism 2 includes several horizontal rollers 21 that are rotatably connected to the support 1. In the present embodiment, the number of the horizontal rollers 21 is four; all the horizontal rollers 21 are sleeved with the same abrasive belt 22, and the The inner wall is in contact with the wood side walls on all the pallets 11 ; the bracket 1 is fixed with a first drive member, which is a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com