Electronic ceramic processing technology

A technology of electronic ceramics and processing technology, which is applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problem of tightening and fixing X-type electronic ceramics of different sizes, increasing the working steps of ceramic drilling, and reducing the success of ceramic drilling rate and other issues to achieve the effect of ensuring success rate, reducing drilling cost and increasing drilling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

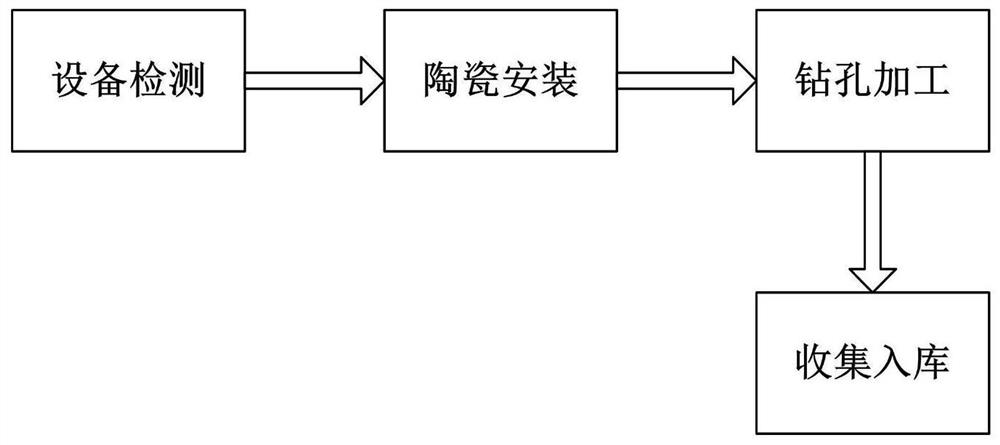

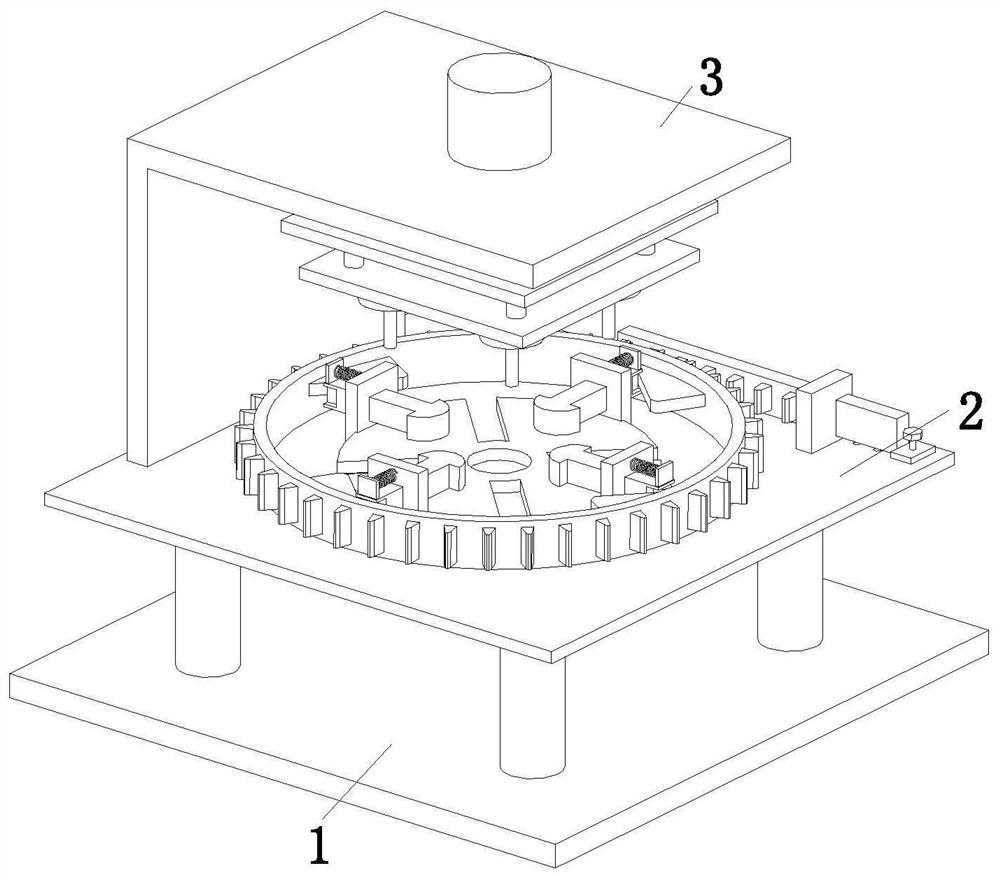

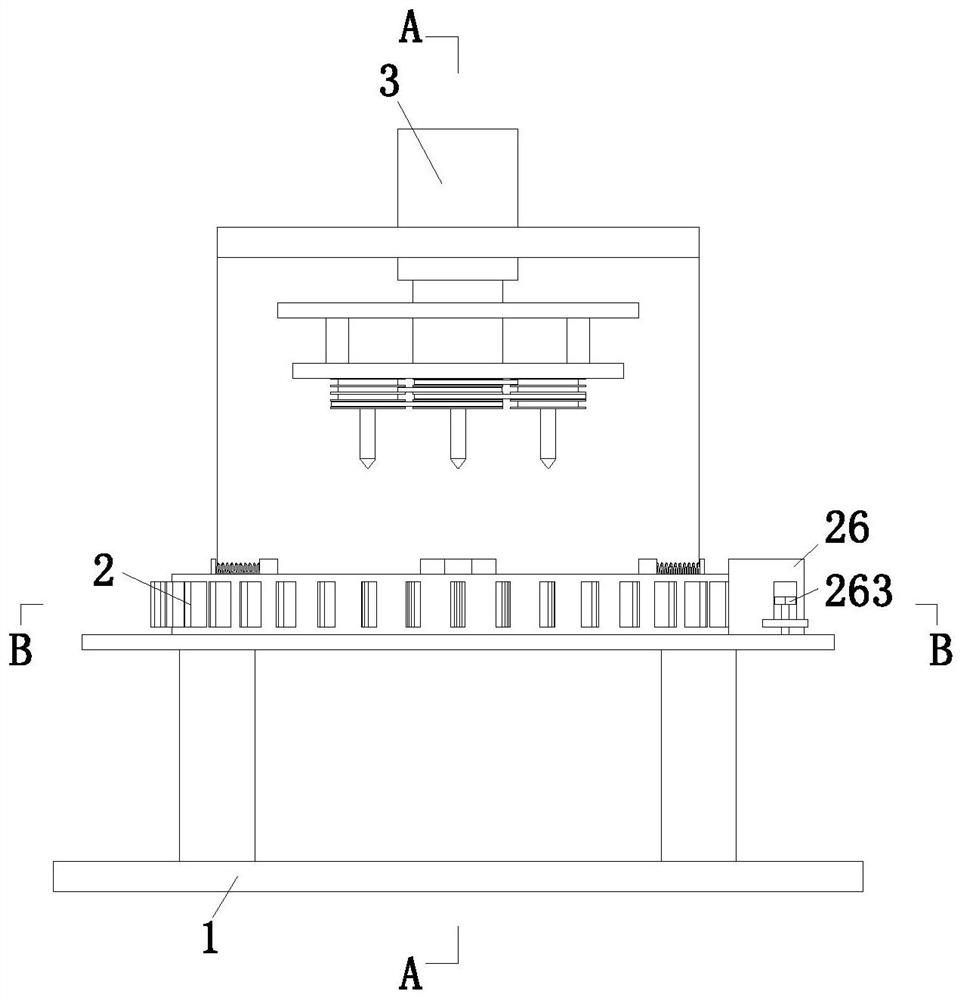

[0032] Such as Figure 1 to Figure 7 As shown, in order to achieve the above object, the present invention adopts the following technical scheme, an electronic ceramic processing technology, which uses a kind of electronic ceramic processing equipment, the electronic ceramic processing equipment includes a base plate 1, a clamping device 2 and a drill Hole device 3, the specific method when using electronic ceramic processing equipment to drill X-type electronic ceramics is as follows:

[0033] S1. Equipment inspection: Before the equipment is used, the equipment is routinely inspected manually;

[0034] S2. Ceramic installation: place the ceramics on the clamping device 2 manually, and the clamping device 2 clamps and fixes the ceramics from multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com