Batching device for plastic processing machine

A technology for processing machinery and plastics, applied in mechanical equipment, springs/shock absorbers, vibration suppression adjustment, etc., can solve problems such as time-consuming and labor-intensive, low batching efficiency, poor mixing effect, etc., to enhance support stability and increase friction Power, ensure the effect of the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

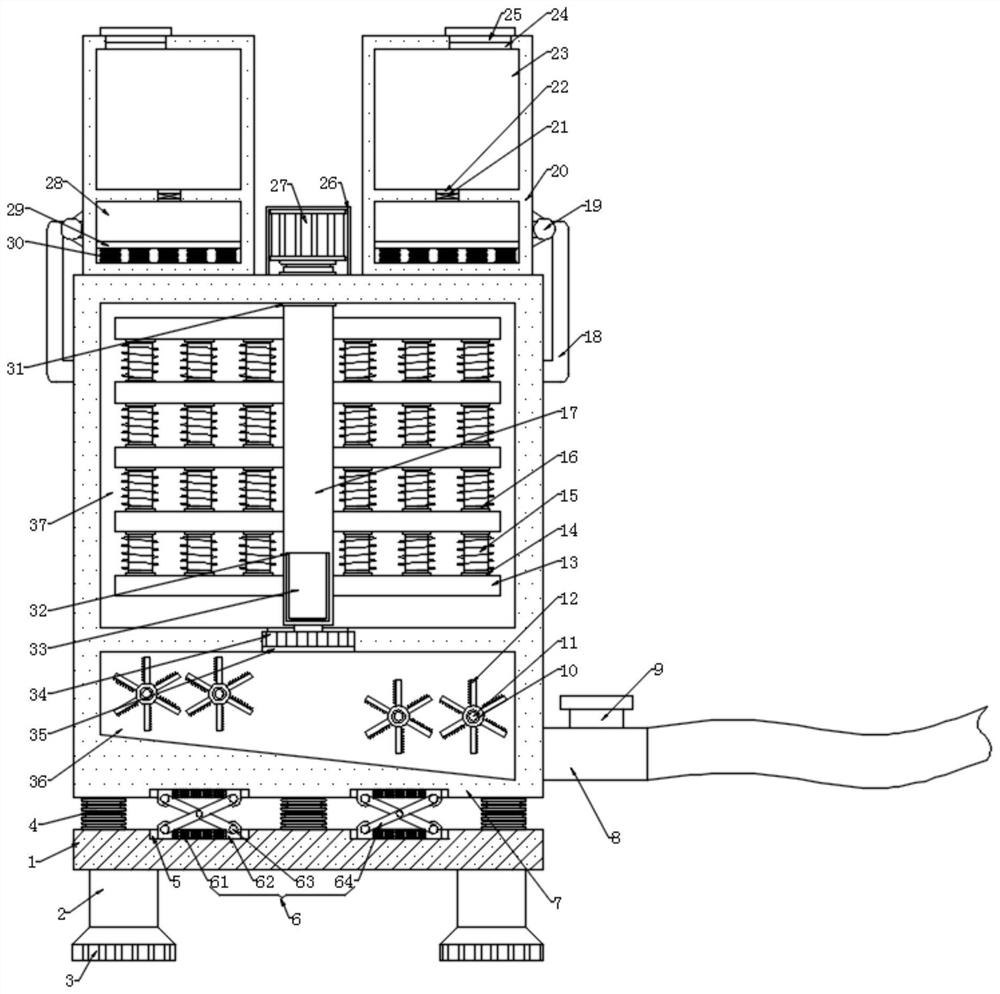

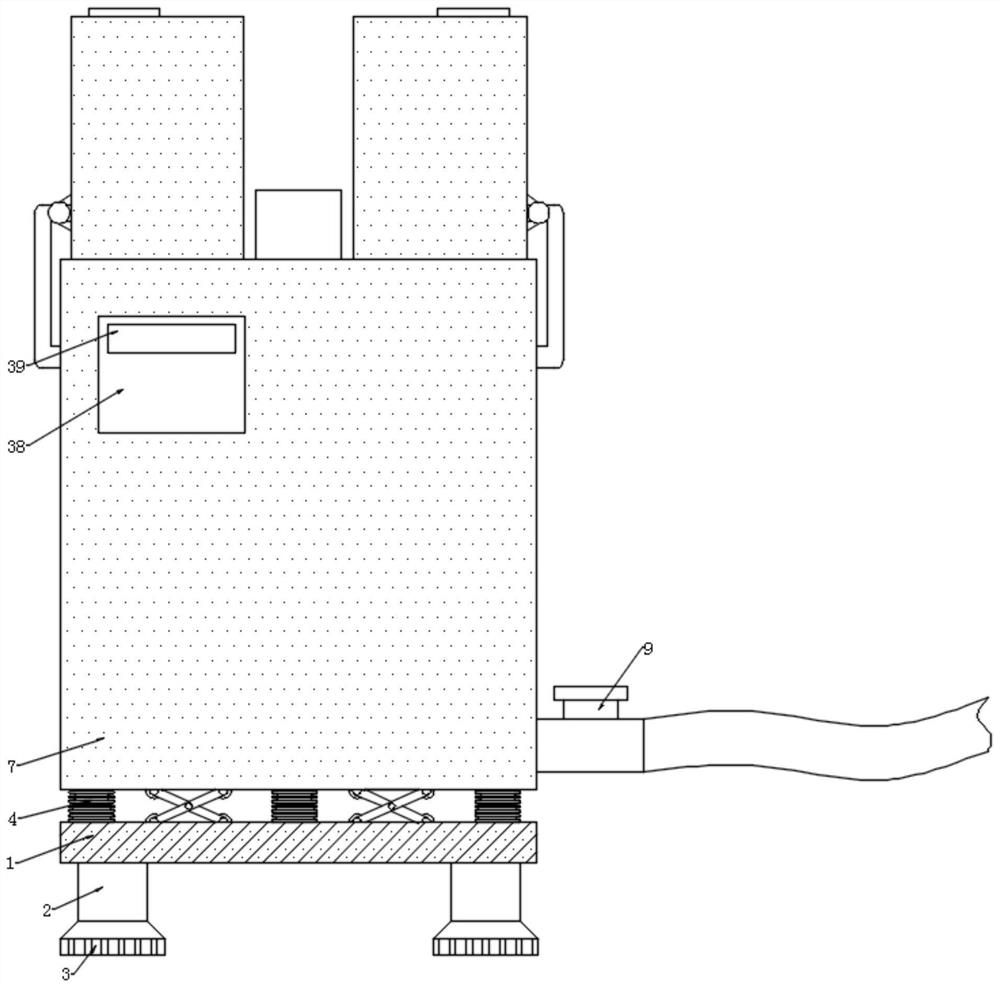

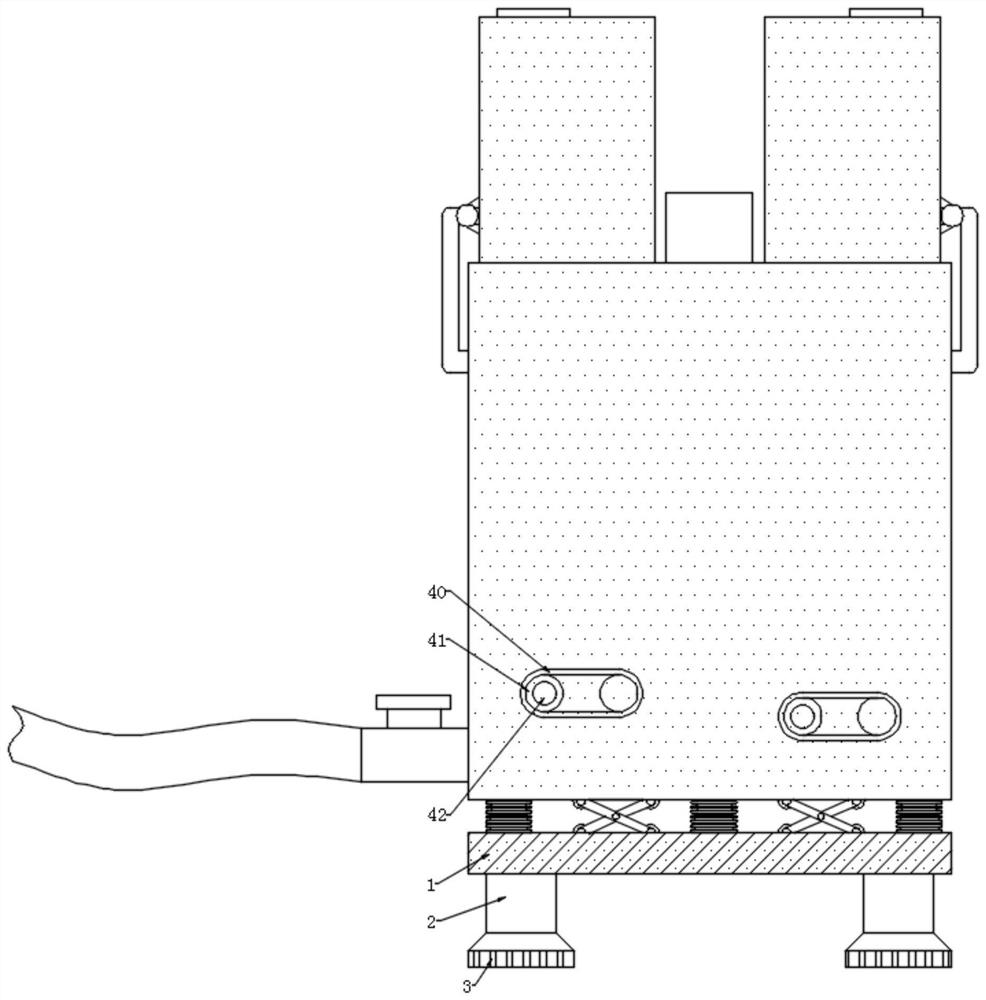

[0027] see Figure 1-4 , the present invention provides the following technical solutions: a batching device for plastic processing machinery, comprising a base 1, the top of the base 1 is fixedly connected with a shock absorber 4, the top of the shock absorber 4 is fixedly connected with a box body 7, the base 1 and the box The opposite surfaces of the body 7 are provided with chute 5, and the shock absorber assembly 6 is slidably connected in the chute 5, and the shock absorber assembly 6 includes a slider 62, a pin shaft 63, a movable rod 64 and a spring 61, two chute 5s up and down. There are two sliding blocks 62 in the sliding connection, the surfaces of the two sliding blocks 62 are movably connected with a movable rod 64 through a pin shaft 63, and a spring 61 is fixedly connected between the two sliding blocks 62. The sliding inside and the activity of the pin shaft 63, through the elasticity of the spring 61, can move through the cross movement of the movable rod 64 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com