Liquid raw material mixing equipment, raw material mixing system and raw material mixing method

A technology of liquid raw materials and mixing equipment, applied in the direction of mixing methods, mixers, chemical instruments and methods, etc., can solve the problems of inaccurate control of proportioning, potential safety hazards, cost waste, etc., to save material costs and investment costs, Effect of improving stability and uniformity and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

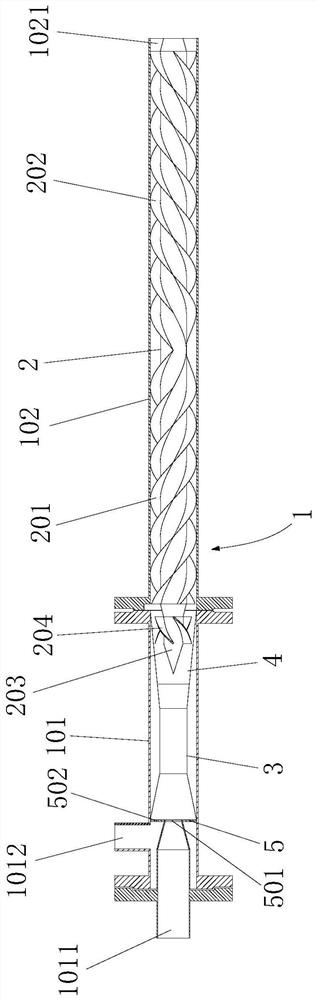

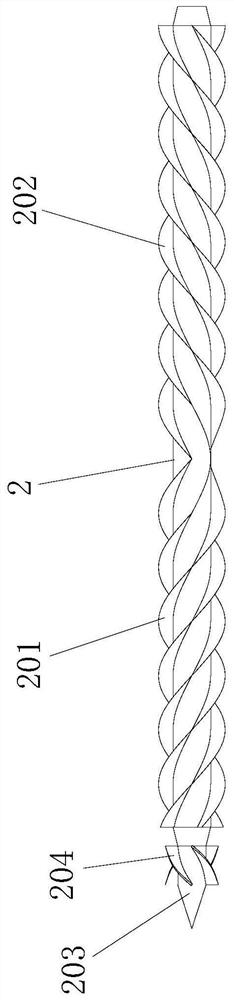

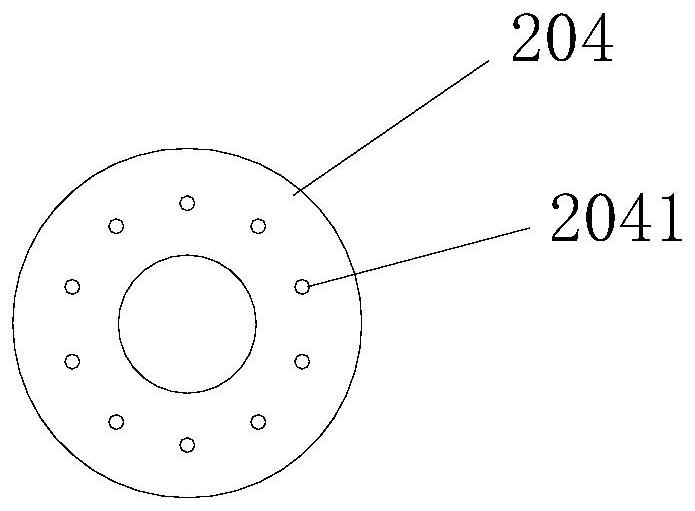

[0046] like figure 1As shown, the present invention provides a liquid feedstock mixing apparatus including a mix tube 1, a mixing tube 1 for flowing from the internal flow of the first liquid feedstock and the second liquid feedstock. Among them: The mixing tube 1 is a cylindrical structure disposed in the horizontal direction, one end of the mixing tube 1 is provided with a first raw material inlet 1011 and a second raw material inlet 1012 in which the inner portion of the mix tube 1, the other end of the mix tube 1 A mixing body outlet 1021 is provided with the inner portion of the mixing tube 1; the inner portion of the mix tube 1 is provided along the axial direction of the mix tube 1, and the outer wall of the mandrel 2 is provided on the outer wall of the mandrel 2 and the first guideline 201 and the first The two-flow flow blade 202, the first guide vane 201 and the second guide blade 202 are helical structures on the outer wall of the core shaft 2 in the outer wall of the ...

Embodiment 2

[0065] like Image 6 As shown, the present invention provides a raw material hybrid system including a batch tank 8 and a liquid material mixing apparatus, a first raw material inlet 1011 of a liquid material mixing apparatus, and a first liquid raw material in which a liquid feed pipe is mixed. The tank connection is connected, and the second raw material inlet 1012 is connected to the mixture outlet 1021 of the liquid feeder mixing apparatus by the transfer pipe 6 and the mixing material of the liquid material mixing apparatus to the ingredients 6 with the ingredient tank 8 through the transfer pipe 6.

[0066] In an alternate embodiment of the invention, such as Image 6 As shown, a valve array 7 is provided on the piping 6 between the liquid material mixing apparatus and the ingredient tank 8. The control of the liquid feeder mixing apparatus and the ingredients between the liquid material mixing apparatus is controlled by the valve array 7, thereby controlling the amount of inp...

Embodiment 3

[0070] The present invention provides a raw material mixing method including the following steps:

[0071] Step S1: Transfer the first liquid feedstock to the mix tube 1 through the first raw material inlet 1011 while simultaneously transporting the second liquid feedstock to the mix tube 1 by the second raw material inlet 1012;

[0072] Step S2: A portion of the first liquid raw material and a portion of the second liquid feedstock sequentially flows through the mix tube 1 in the guide flow of the first guiding blade 201 and the second guide blade 202, and the other portion of the first liquid material and the other of the second The liquid raw material sequentially flows through the mix tube 1 directly through each of the first fluid apertures 2011 and the second fluid hole 202 on the second fluid vane 202 in the first passage blade 201;

[0073] Step S3: The first liquid raw material and the second liquid feedstock are fully mixed in the mix tube 1, from the mixture outlet 1021...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com