Novel roller press

A roller press, a new type of technology, applied to presses, presses using rotating pressure components, manufacturing tools, etc., can solve the problems of reducing work efficiency, increasing work costs, and not being able to play the role of roller presses well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment, further illustrate the present invention.

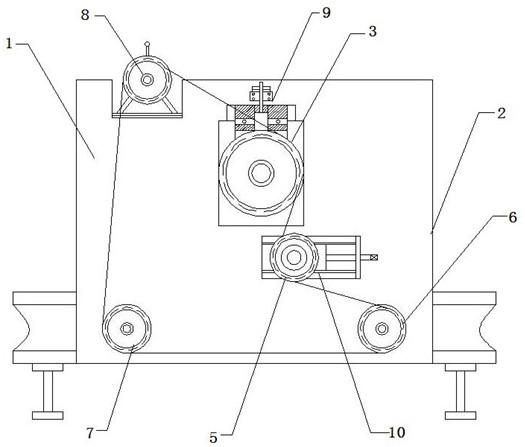

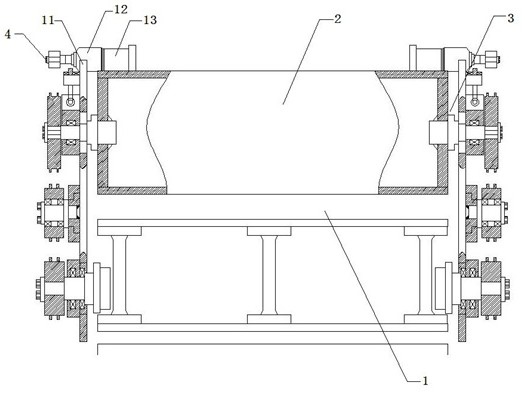

[0021] see figure 1 , figure 2 It can be seen that a novel rolling machine of the present invention, the rolling machine body 1 is provided with a rolling frame 2, and the rolling frame 2 is provided with a rolling structure, a speed control system, and a transmission system, and the described rolling structure is Roller 3, the two ends of roller 3 are provided with transmission gear, described transmission system comprises transmission gear, sprocket 4, is provided with transmission chain between transmission gear and sprocket 4, and sprocket 4 comprises first sprocket 5 , the second sprocket 6, the third sprocket 7 and the fourth sprocket 8, the transmission gear at both ends of the roller 3 is provided with a lifting device, the first sprocket 5 is provided with a moving structure, and the described lifting device is the first A sliding frame 9, the moving structure is the second sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com