Hub Motors for Unmanned Vehicles

A technology for hub motors and unmanned vehicles, which is applied in the direction of electromechanical devices, vehicle components, electrical components, etc., can solve the problems of limited load capacity of hub motors, shorten the life of bearings and hubs, and the inapplicability of hub motors, etc., to achieve a reliable fixing method , Improve the effect of uneven force and prevent axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

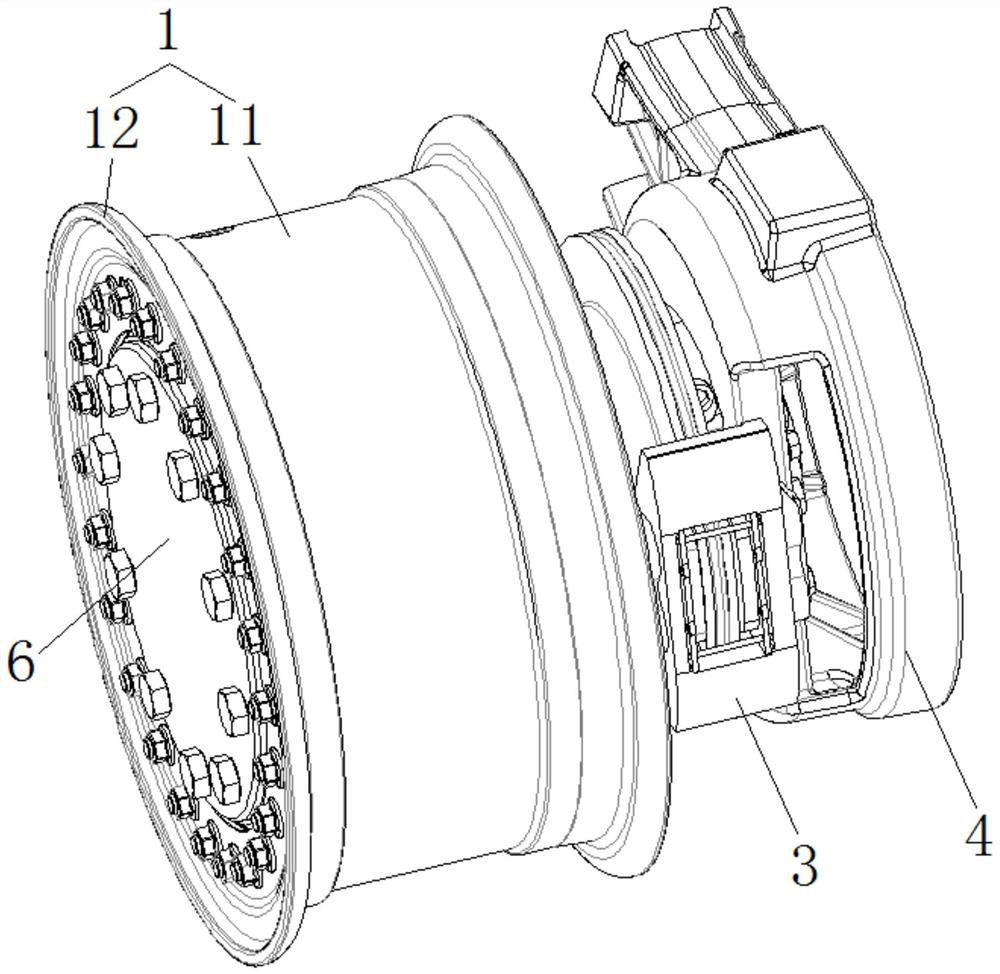

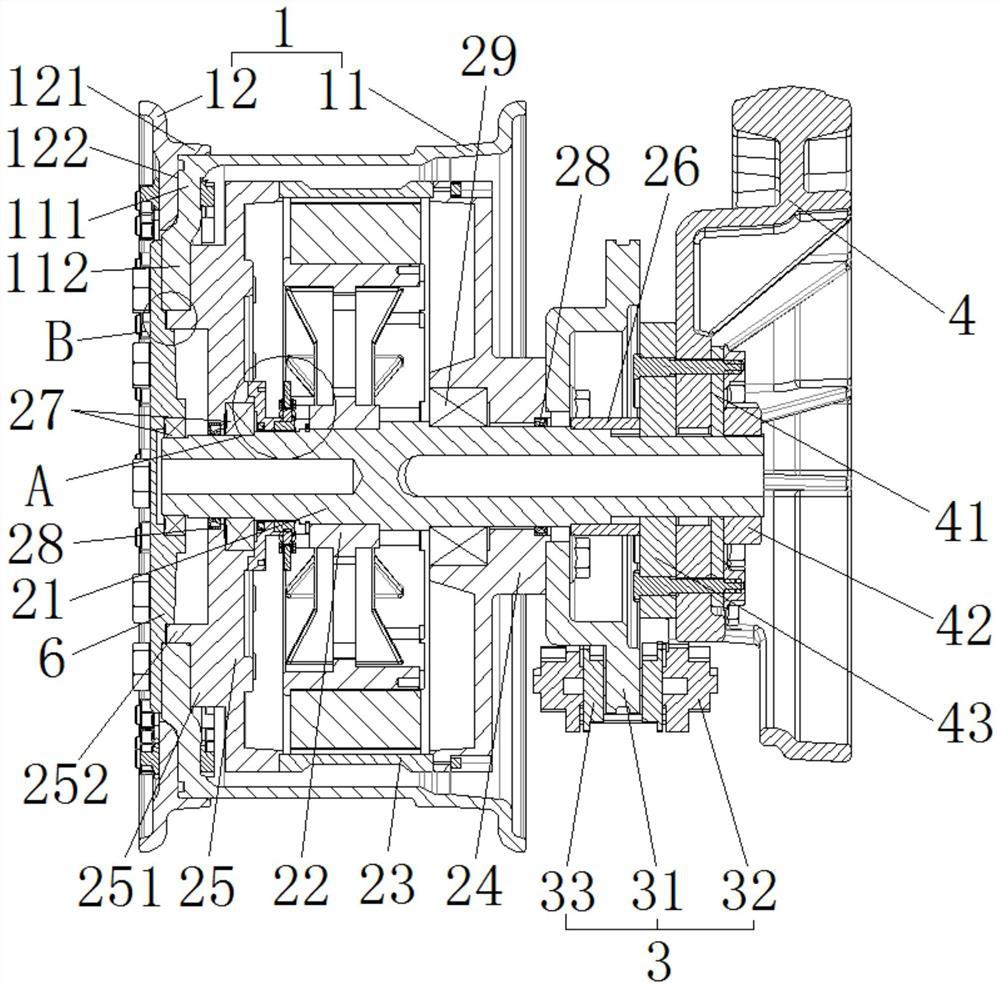

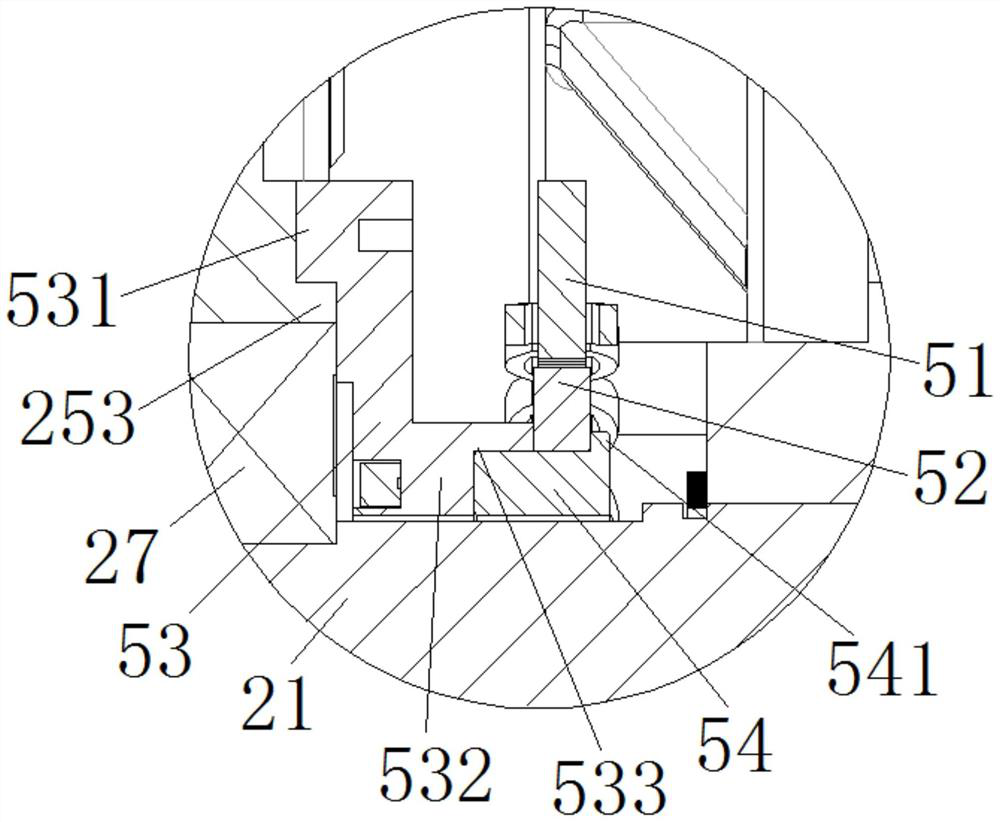

[0033] Such as Figure 1 to Figure 10 As shown, the hub motor used for unmanned vehicles includes a motor body 2, and the motor body 2 includes a central shaft 21, a stator 22, a rotor 23 and a resolver 5, and hub fixing end caps 25 are installed on both sides of the rotor 23 and the disc brake fixed end cover 24, the rotor 23, the hub fixed end cover 25, and the disc brake fixed end cover 24 are all connected by bolts, the rotor 23 is arranged on the outside of the stator 22, and between the rotor 23 and the stator 22 An air gap is formed. The rotor 23 includes magnetic steel glued on its annular inner wall. In fact, an air gap is formed between the inner wall of the magnetic steel and the outer wall of the stator 22. A temperature control resistor is installed on the winding of the stator 22. The control resistor is connected with an external cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com