A kind of ultra-clear float glass with blue edge color and production method thereof

A technology of ultra-clear float glass and its production method, which is applied in the direction of glass production, etc., and can solve problems such as increased production costs, increased production costs, unfavorable glass color continuity and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

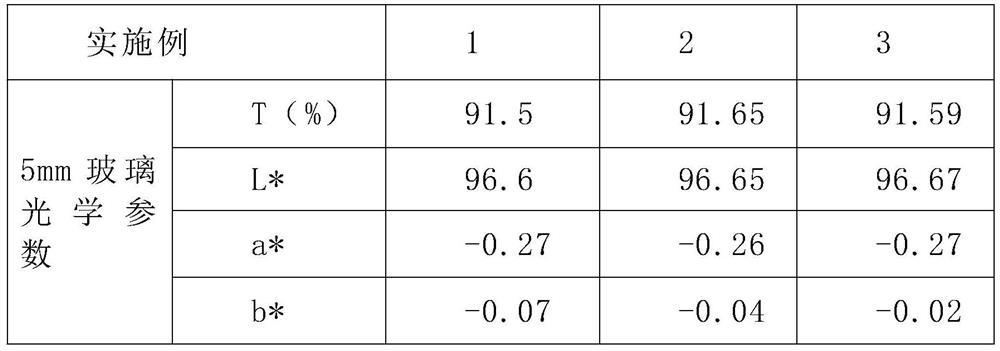

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0022] The present invention will be further elaborated below through specific examples.

[0023] The table below is a representative example of specific glass composition

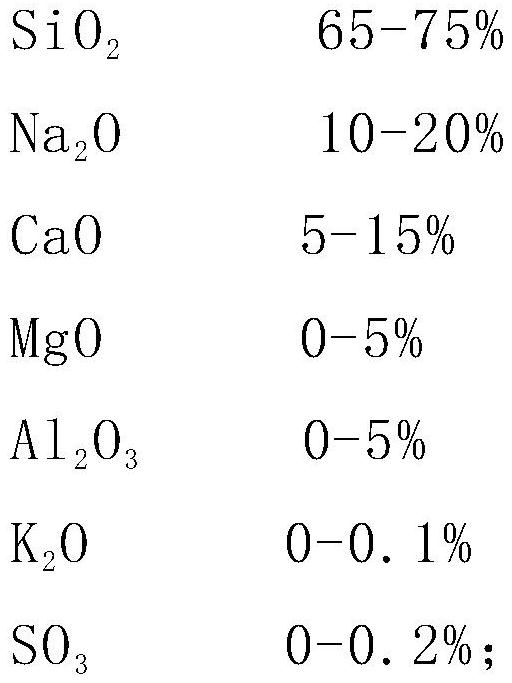

[0024] base glass composition

[0025] SiO 2

Al 2 o 3

CaO MgO Na 2 o

Composition (wt%) 72.40 0.47 9.51 3.47 14.21

[0026] The embodiment that adds the tinting agent (accounting for the percentage content of base glass weight) given by the present invention at above-mentioned base glass composition sees the following table:

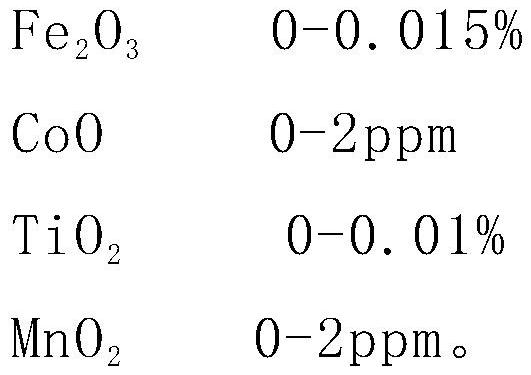

[0027] Fe 2 o 3 (wt%)

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com