Foldable hidden assembly type fireproof curtain mounting structure

A technology for installing structures and fire curtains, applied in fire doors, building components, fire rescue, etc., can solve problems such as low installation efficiency, failure of fire shutters to stop immediately, cumbersome installation procedures of fire shutters, etc., to achieve timeliness Good, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

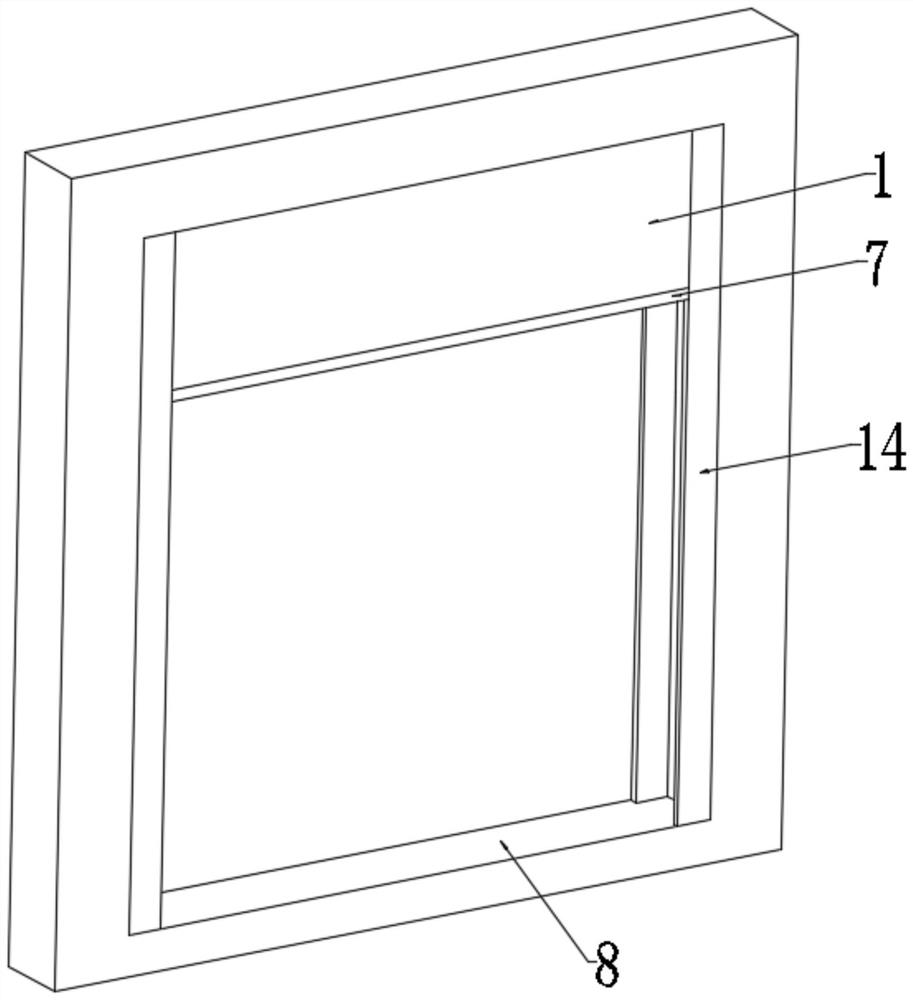

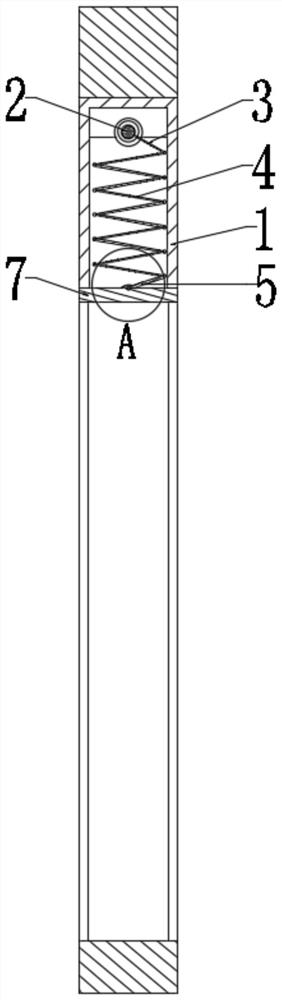

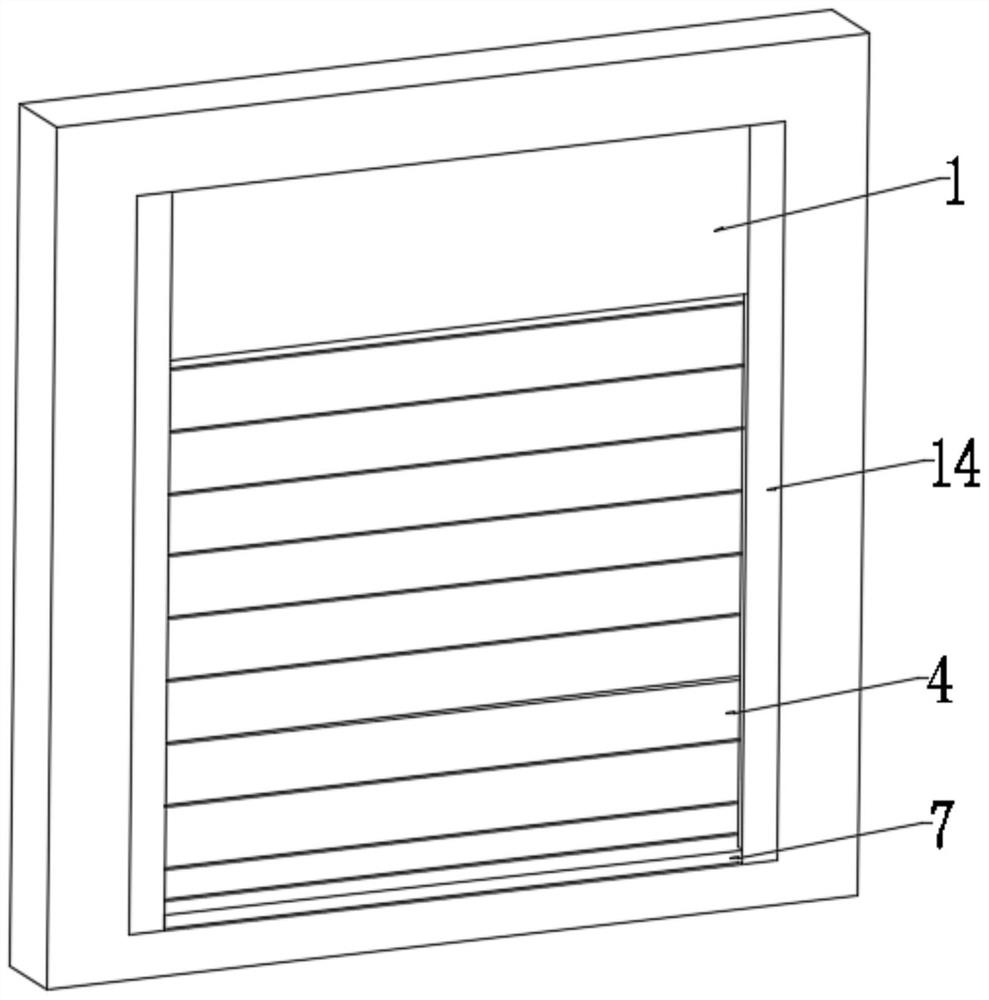

[0030]SeeFigure 1 to Figure 7This embodiment provides a foldable hidden assembled firecrew mounting structure, wherein the storage cabinet 1, the connecting shaft 2, the upper connecting plate 3, fire board 4, the lower connection plate 5, electromagnet 6 are first provided. The weight plate 7, the storage cabinet 1 is a long square case structure of the opening, and the top of the storage cabinet 1 is fixed to the top of the mounting groove 8, and the opposite sides of the connection shaft 2 connects the contained side walls. The multi-block fire plate 4 is connected to form a folded fire curtain, and the fire plate 4 is located within the storage cabinet 1, and the two fire board 4 is hinged between the uppermost fire plate 4 connected to the connecting shaft 2 by the upper connecting plate 3, located in the most The lower fire plate 4 is connected to the weight plate 7 by the lower connection plate 5, and the electromagnet 6 is two fixed grooves 10 mounted on both sides of the mo...

Embodiment 2

[0039]SeeFigure 1 to Figure 7The figure shows a foldable hidden assembled fire curtain mounting structure provided by the second embodiment of the present invention, and the present embodiment further makes the following as an improved technical solution based on the above embodiment: connection The shaft 2 is connected to the inner side wall of the receiving cabinet 1 by the bearing housing 11, and the bearing housing 11 is fixed to the inner side wall of the storage cabinet 1, and the end of the connecting shaft 2 is inserted into the bearing seat 11.

Embodiment 3

[0041]SeeFigure 1 to Figure 7The figure shows a foldable hidden assembly type fire curtain mounting structure provided by the third embodiment of the present invention, and the present embodiment further makes the following as an improved technical solution based on the above embodiment: The upper end of the connecting plate 3 is provided with a connecting pipe 12, and the connecting pipe 12 is arranged on the connecting shaft 2, and the lower end of the upper connecting plate 3 is hinged from the fire board 4.

[0042]Specifically, seeFigure 1 to Figure 7The upper end of the lower connection plate 5 is hinged from the fire plate 4, and a hinge 13 is provided on the top surface of the counterweight plate 7, and the lower end of the lower connection plate 5 is hinged to the hinge 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com