Experimental device and method for detecting gas-phase fracturing working pressure and fracturing effect

A technology of working pressure and experimental equipment, which is applied in the directions of measurement, earthwork drilling, mining fluid, etc., can solve the problems of imperfect equipment and methods, large error of test results, heavy workload, etc., and achieve low cost of use and maintenance, and convenience Research and promote the application, use the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

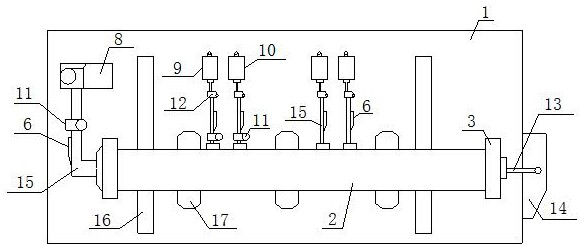

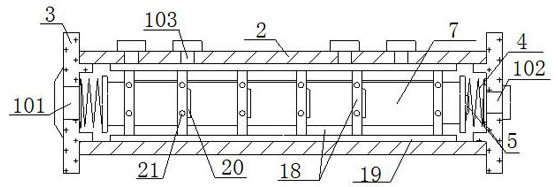

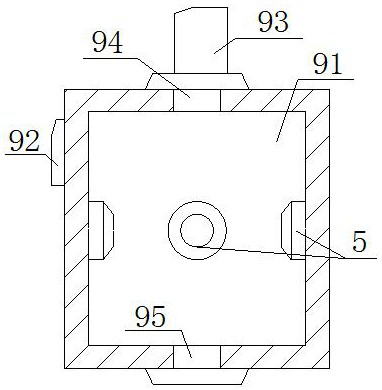

[0028] Such as Figure 1-4 As shown, an experimental device for detecting the working pressure and fracturing effect of gas-phase fracturing, including a bearing base 1, an experimental chamber 2, a sealing cover 3, a bearing spring 4, a mechanical pressure sensor 5, a fluid pressure sensor 6, a gas-phase fracturing Device 7 , booster pump 8 , pressure detection experiment chamber 9 , fracturing effect detection experiment chamber 10 , control valve 11 , pressure limiting valve 12 , control wire 13 and drive circuit 14 . The bearing base 1 is a frame structure with a rectangular cross section and the axis is parallel to the horizontal plane. The experimental cavity 2 is connected to the upper end surface of the bearing base 1 and distributed parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com