Adjusting method for restraining inclination angle rotation errors of two-end supporting shafting structure

An assembly and adjustment method and a technology for supporting shafts, which are applied to rotating parts, shafts, and bearings that resist centrifugal force, can solve the problems of insufficient coaxial accuracy of bearing holes, difficult rotation accuracy, and incompleteness, etc., to reduce the dependence on assembly and adjustment experience , the steps are clear, and the effect of suppressing the inclination rotation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

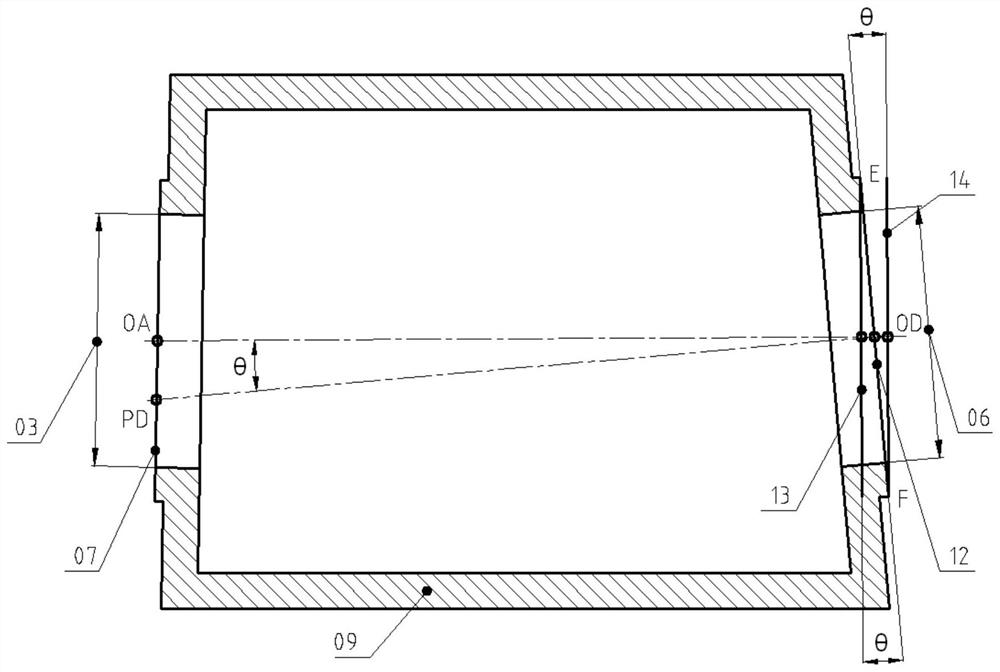

[0027] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] The concept and test method of the inclination angle rotation error involved in the present invention can be found in GJB 1801 "Test Methods for Main Performance of Inertial Technology Test Equipment".

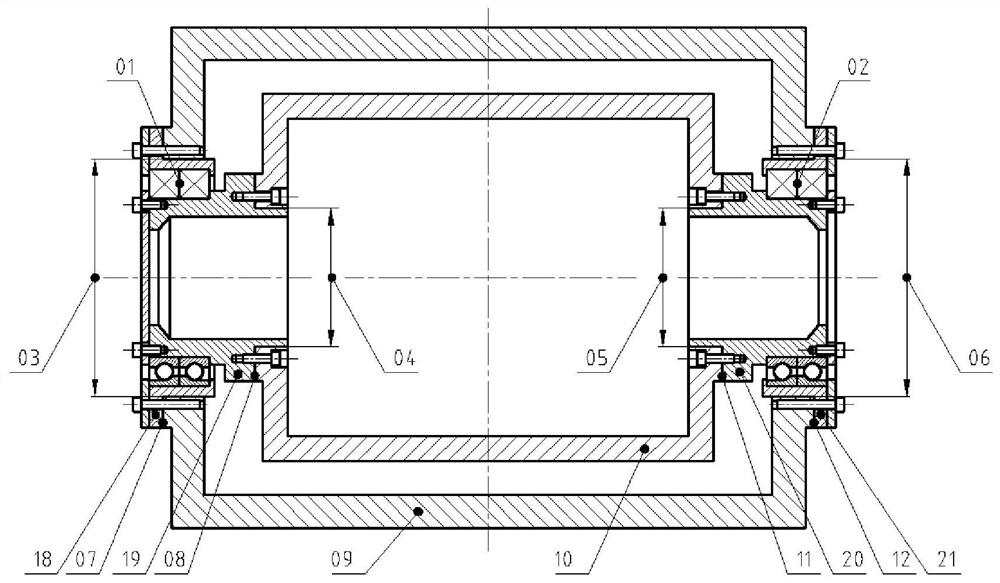

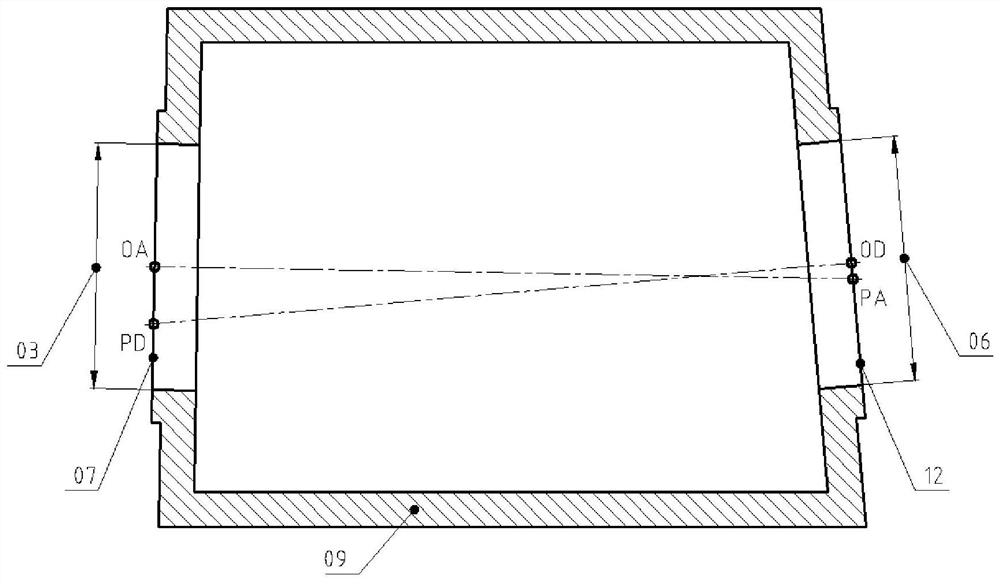

[0029] The model of a kind of two-end supporting shafting structure designed by the present invention is as follows: figure 1 As shown, the shafting structure is composed of four necessary parts: the left end bearing pair assembly 01, the right end bearing pair assembly 02, the outer frame 09 and the inner frame 10.

[0030] The left end bearing pair assembly 01 is composed of a left bearing seat 18, a left shaft 19 and a back-to-back bearing pair; the right end bearing pair assembly 02 is composed of a right be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com