An automatic sorting jaw crusher and its usage method

A jaw crusher, automatic classification technology, applied in grain processing, etc., can solve the problems of manpower, material resources and time cost, uneven wear of jaw plates, insufficient utilization of jaw plates, etc., to achieve convenient operation, uniform wear, and improved Effect of Jaw Plate Utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

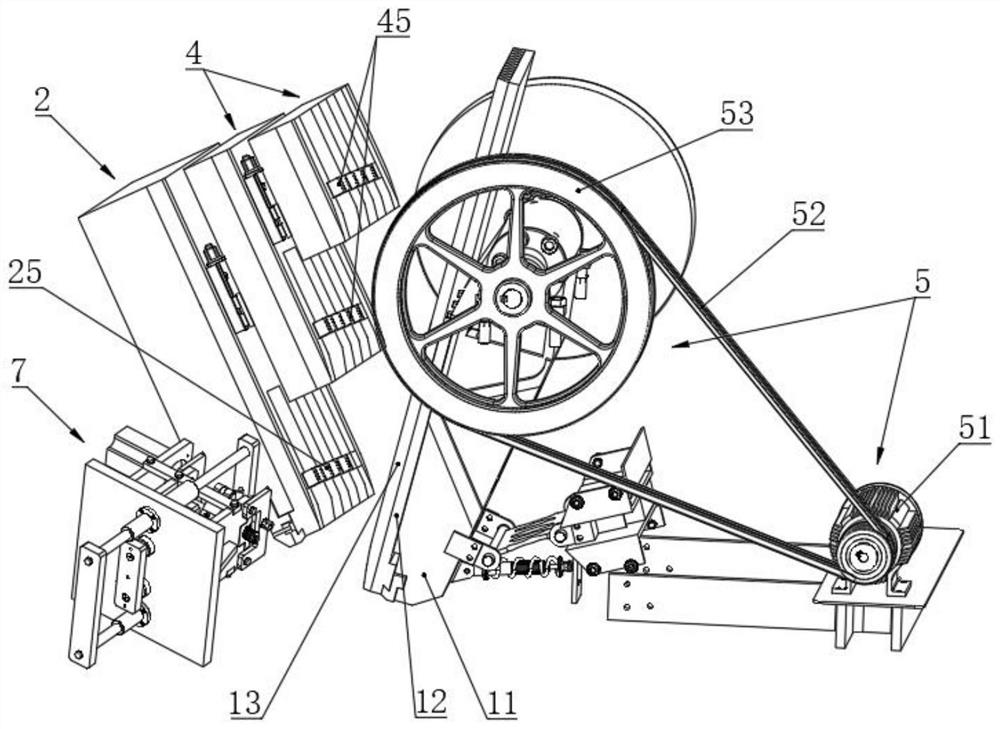

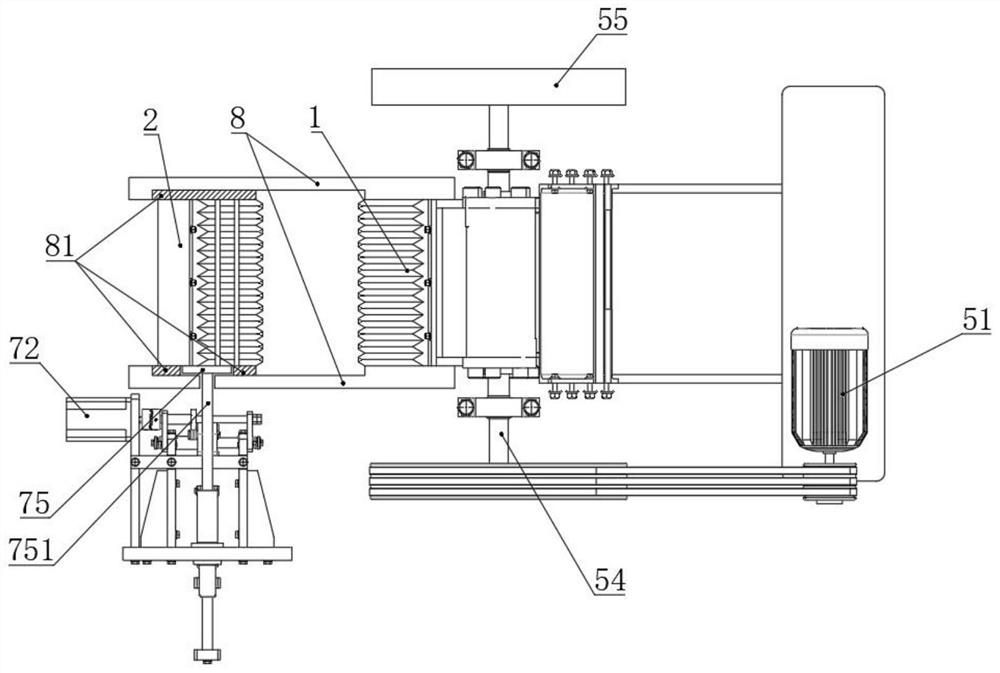

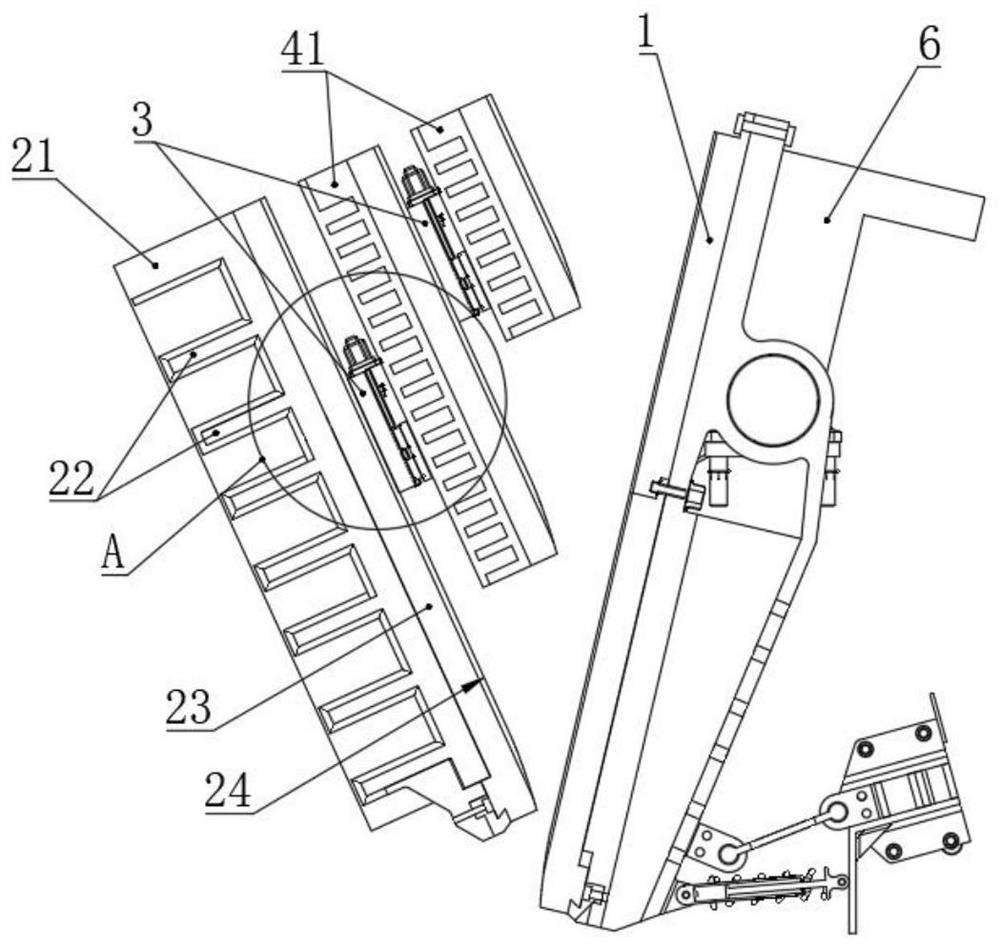

[0074] Such as Figure 1-9 As shown, an automatic classification jaw crusher includes movable jaw 1, main fixed jaw 2, multi-stage fixed jaw 4, power mechanism 5, reciprocating mechanism 6, vibration mechanism 7 and frame, movable jaw 1, main fixed jaw Jaw 2, power mechanism 5, reciprocating mechanism 6 and vibration mechanism 7 are all installed on the frame, the upper end of movable jaw 1 is connected with power mechanism 5 through reciprocating mechanism 6, the lower end of movable jaw 1 is hinged with the frame, and movable jaw 1 is connected with the The jaw 2 is placed in a "V" shape, the multi-stage fixed jaw 4 is stepped and installed on the main fixed jaw 2, the movable jaw 1 and the main fixed jaw 2 are equipped with guard plates 8 on both sides, and the guard plate 8 on one side There is a tie rod through hole, and the vibrating mechanism 7 is connected to one side of the main fixed jaw 2 through the tie rod through hole, and the main fixed jaw 2 is slidably connect...

Embodiment 2

[0096] This embodiment is a further improvement of the previous embodiment, such as Figure 1-9 As shown, an automatic classification jaw crusher includes movable jaw 1, main fixed jaw 2, multi-stage fixed jaw 4, power mechanism 5, reciprocating mechanism 6, vibration mechanism 7 and frame, movable jaw 1, main fixed jaw Jaw 2, power mechanism 5, reciprocating mechanism 6 and vibration mechanism 7 are all installed on the frame, the upper end of movable jaw 1 is connected with power mechanism 5 through reciprocating mechanism 6, the lower end of movable jaw 1 is hinged with the frame, and movable jaw 1 is connected with the The jaw 2 is placed in a "V" shape, the multi-stage fixed jaw 4 is stepped and installed on the main fixed jaw 2, the movable jaw 1 and the main fixed jaw 2 are equipped with guard plates 8 on both sides, and the guard plate 8 on one side There is a tie rod through hole, and the vibrating mechanism 7 is connected to one side of the main fixed jaw 2 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com