Full-automatic medicine pestling device

A fully automated, medicine box technology, applied in the field of medical devices, can solve the problems of incomplete automatic operation, uneven pounding effect, poor pounding effect, etc., and achieve good pounding effect, high degree of automation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

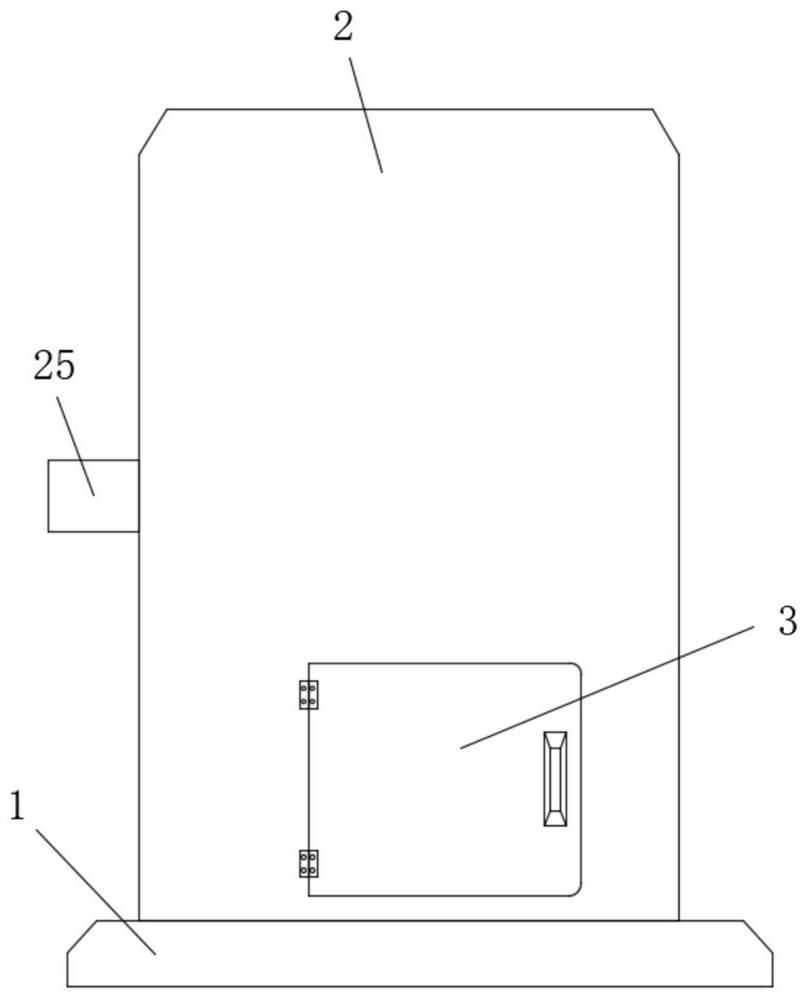

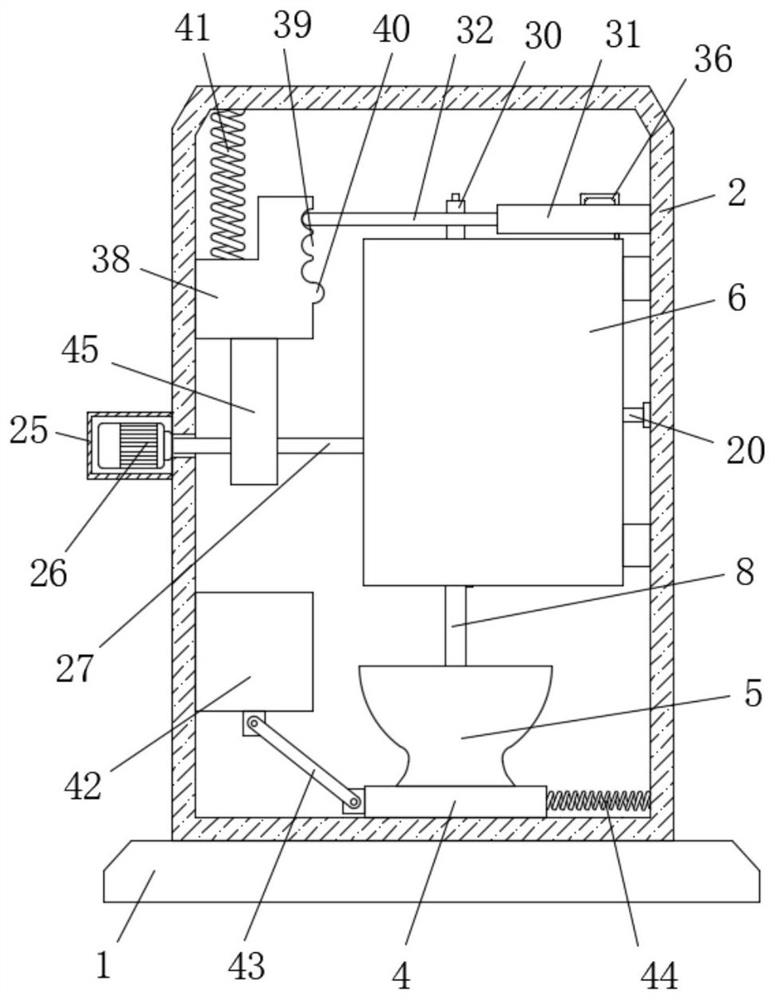

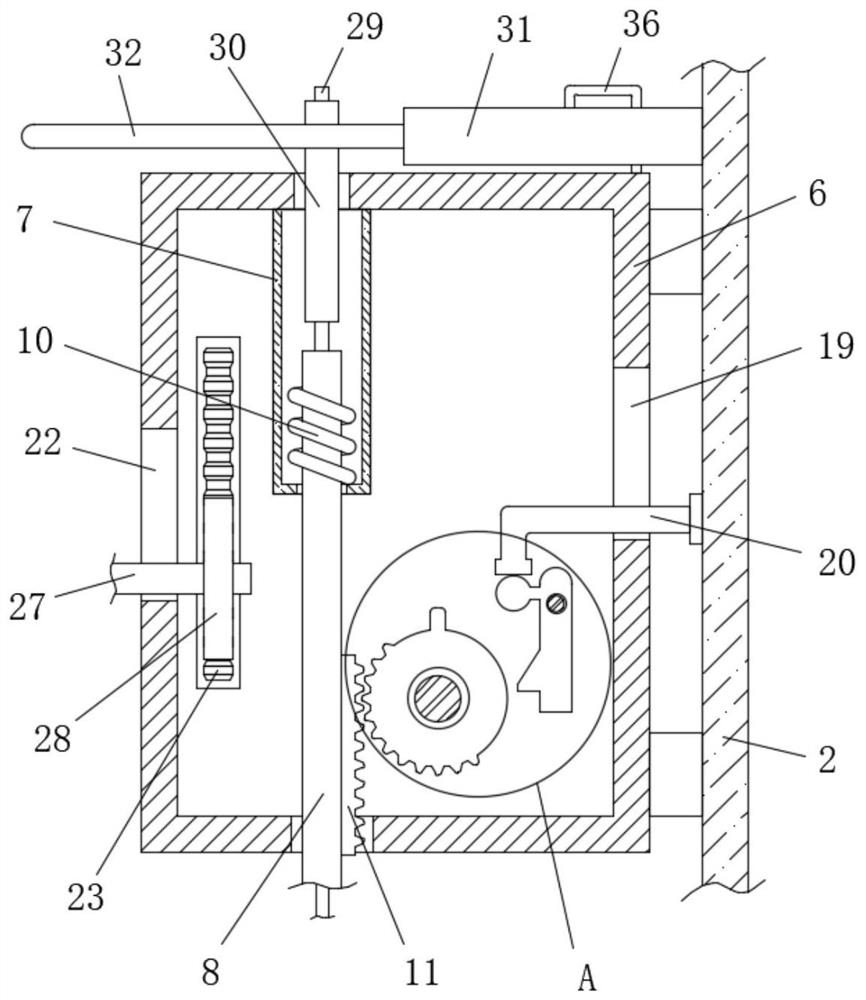

[0036] refer to Figure 1-10 , a fully automatic pounding device, comprising a base 1, a pounding box 2 fixedly connected to the top of the base 1, a box door 3 hinged at the bottom of one side of the pounding box 2, and a sliding door 3 connected to the bottom inner wall of the pounding box 2. Table 4, the top of the sliding table 4 is provided with a medicine cup 5, the side inner wall of the pounding box 2 is slidably connected with a moving box 6, and the top inner wall of the moving box 6 is fixedly connected with a first sleeve 7, and the first sleeve 7 is The top is open and the bottom is closed. The bottom of the first sleeve 7 is slidably connected with a pestle rod 8. The pestle rod 8 is a tubular structure. One side of the pestle rod 8 runs through the bottom of the moving box 6 and extends into the medicine cup 5. The bottom end of the rod 8 is rotatably connected with a pestle head 9, and the bottom of the pestle head 9 is in contact with the bottom inner wall of ...

Embodiment 2

[0038] Further improved on the basis of embodiment one:

[0039] In the present invention, the limit assembly includes a first rotating rod 12 and a second rotating rod 15 respectively rotatably connected inside the moving box 6, and the second rotating rod 15 is located obliquely above the side of the first rotating rod 12 away from the pestle rod 8 , the first rotating rod 12 is fixedly covered with a first half gear 13, and the side of the pestle bar 8 near the bottom of the moving box 6 is provided with a first rack 11, and the first rack 11 is meshed with the first half gear 13 , when the pestle rod 8 moves up and down, the meshing movement between the first rack 11 and the first half gear 13 can drive the first half gear 13 to rotate.

[0040] In the present invention, a bump 14 is provided on the top of the first half gear 13, and the bump 14 is located on the smooth section of the first half gear 13, and a rotating plate 16 is fixedly set on the second rotating rod 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com