Ceramic raw material pug mill for domestic ceramic processing

A technology of ceramic processing and clay refining machine, which is applied in the field of ceramics, and can solve the problems of broken clay, easy adhesion on the inner wall of the machine, inconsistent particle gaps before and after the clay, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Such as Figure 1-Figure 5 Shown:

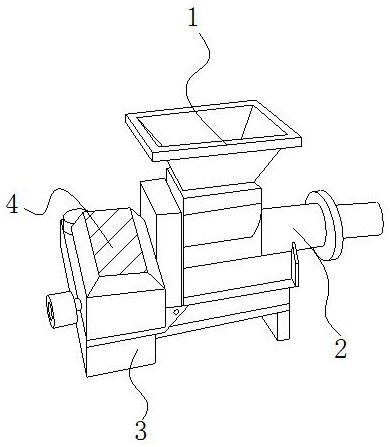

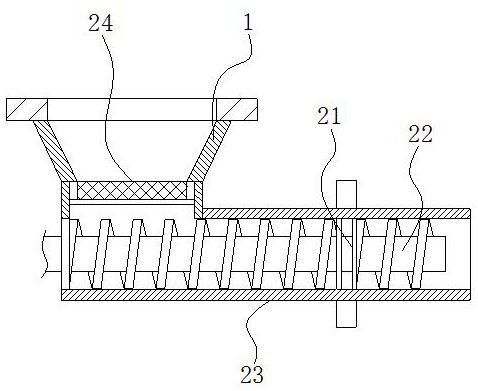

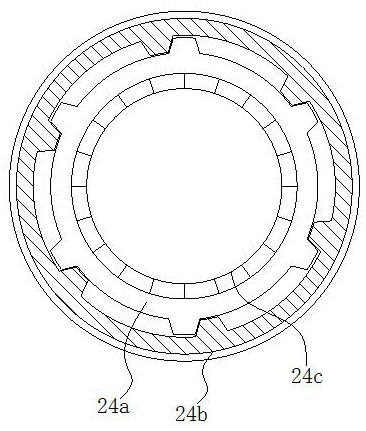

[0025] The present invention is a raw material mud refining machine for daily ceramic processing. Its structure includes a material inlet 1, a mud refining mechanism 2, a fixed platform 3, and a motor 4. The lower end of the motor 4 is welded on the left side of the upper end of the fixed platform 3. The mud refining mechanism 2 is installed on the right side of the upper end of the fixed platform 3. The mud refining mechanism 2 runs through the inside of the motor 4. The material inlet 1 is embedded in the upper end of the mud refining mechanism 2. The mud refining mechanism 2 is equipped with an extrusion Hole 21, rotating mechanism 22, mud practice cylinder 23, blocking mechanism 24, described extrusion hole 21 is snapped in the inside of mud practice cylinder 23, and the outer side of described rotation mechanism 22 is fit with the inner side of mud practice cylinder 23, and described blocking mechanism 24 is installed on the upp...

Embodiment 2

[0032] Such as Figure 6-Figure 7 Shown:

[0033] Wherein, the rotating mechanism 22 is provided with a rotating shaft w1, a supporting plate w2, a guiding mechanism w3, and a rotating thread w4. The rotating thread w4 is welded on the outside of the rotating shaft w1, and the supporting plate w2 is installed on the outside of the rotating thread w4. The guide mechanism w3 is embedded and fixed on the outside of the support plate w2, and the guide mechanism w3 is in clearance fit with the inner side of the mud training cylinder 23. There are six support plates w2, which are evenly distributed in a ring around the rotation axis w1, and each supports There are three guiding mechanisms w3 in the plate w2, so that the rotation of the motor 4 drives the rotating shaft w1 to rotate, so that the guiding mechanism w3 on the outside of the rotating thread w4 cooperates with the inner side of the clay training cylinder 23, so that the guiding mechanism w3 in the supporting plate w2 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com