Trimming and leveling device for house building prefabricated wallboards and using method thereof

A technology of prefabricated wall panels and leveling devices, which is applied in the direction of manufacturing tools, stone processing tools, and work accessories, which can solve the problems of resource waste, cutting damage of rear wall panels, and low practicability, so as to avoid vibration and firmly grip the ground , the effect of increasing the force bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

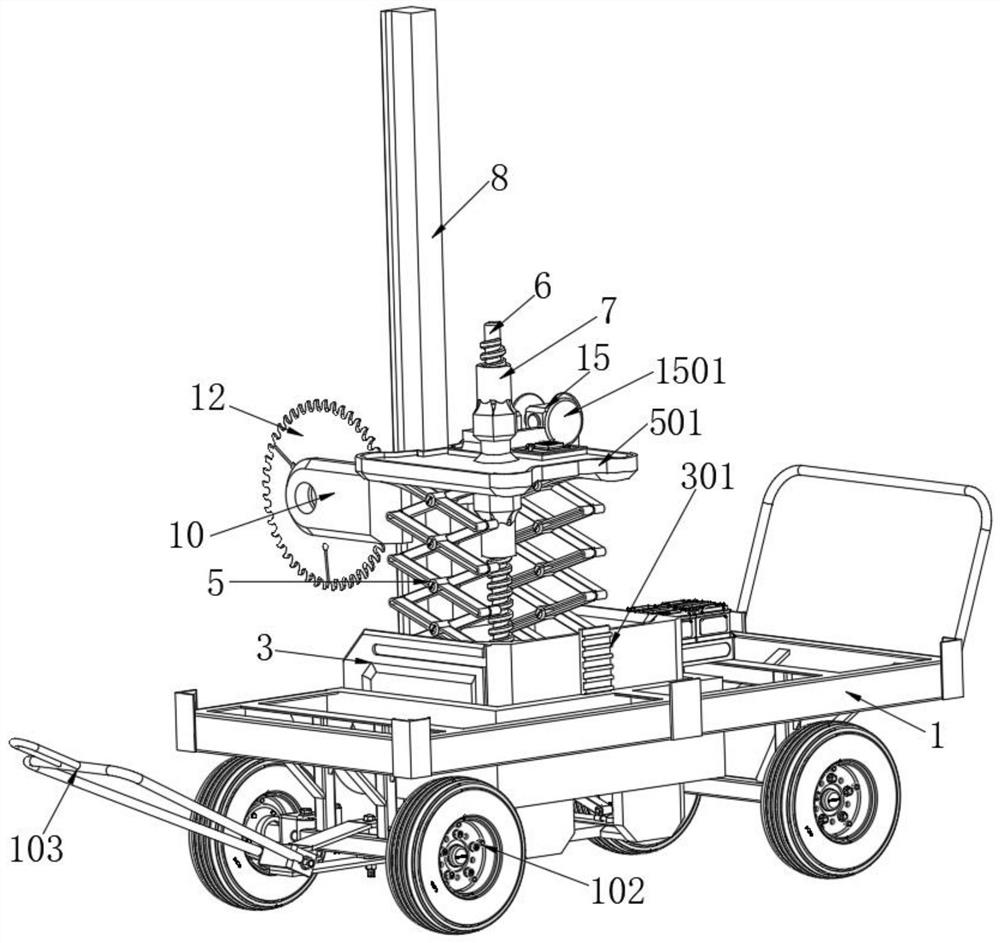

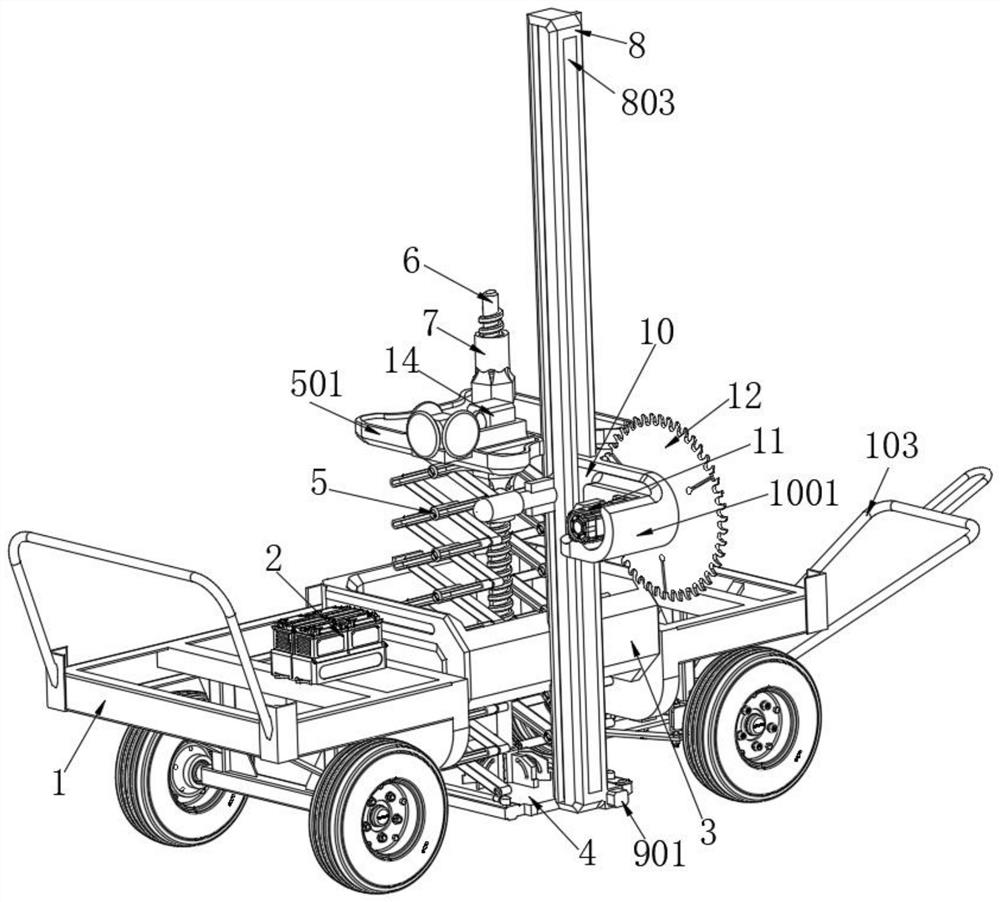

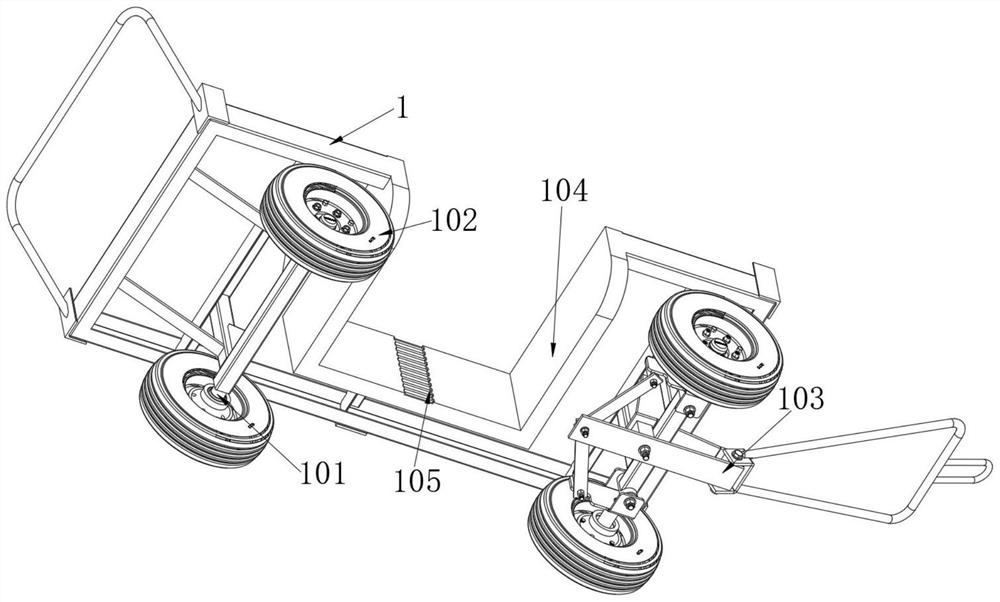

[0036] see Figure 1-8 , the present invention provides a technical solution: a trimming and leveling device for prefabricated wall panels in house construction, including a car body 1, the inner side wall of the car body 1 is provided with a fixed moment groove 104, and the inner side wall of the fixed moment groove 104 slides The fixed frame 3 is connected, the lower surface of the fixed frame 3 is welded with a grounding plate body 4, the upper surface of the grounding plate body 4 is welded with a telescopic frame 5, the upper surface of the grounding plate body 4 is welded with a fixed sleeve 401, and the telescopic frame 5 The upper surface is fixedly connected with a top tray 501, the inner wall of the top tray 501 is threaded with a threaded rod 6, the lower part of the outer surface of the threaded rod 6 is welded with the fixed sleeve 401, and the inner wall of the grounding plate 4 is welded with a guide rail housing 8, The outer surface of the guide rail housing 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com