Improvement-based ink droplet charging small character nozzle device

A nozzle and character technology, which is applied in the field of ink drop charging small character nozzle device, can solve the problems of nozzle softening, too many nozzles, unfavorable cleaning of small character nozzles, etc., and achieve the effect of ensuring temperature adjustment and avoiding nozzle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

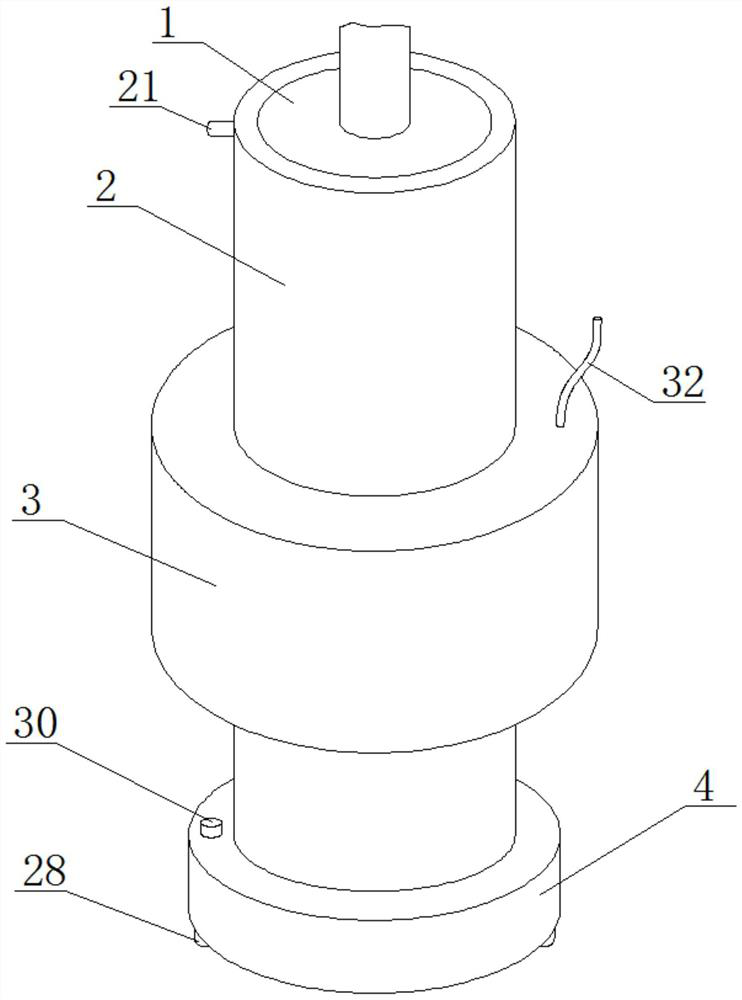

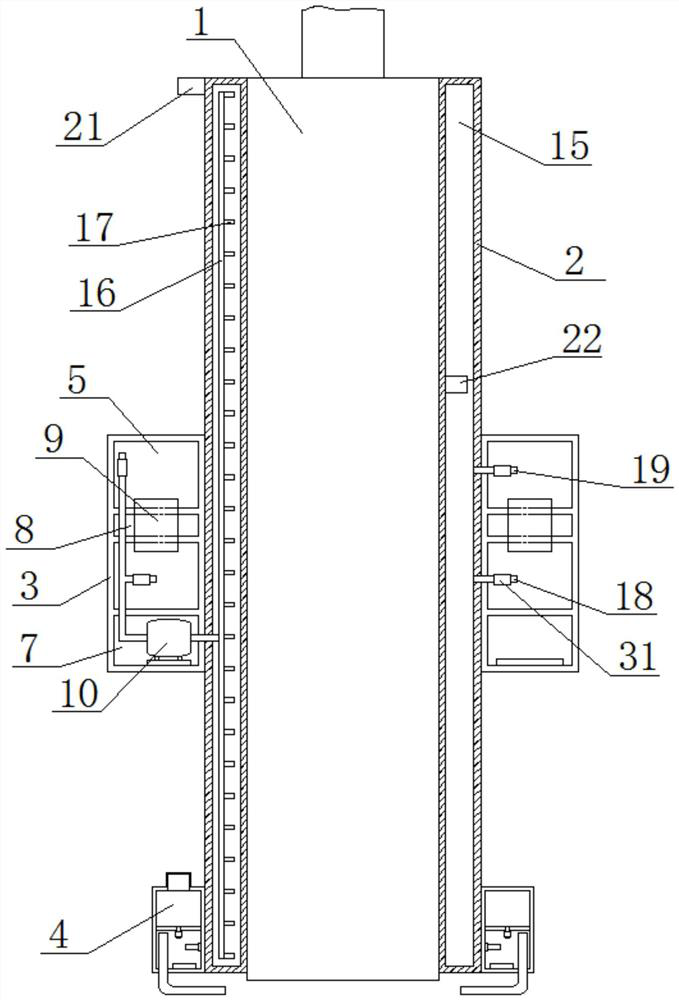

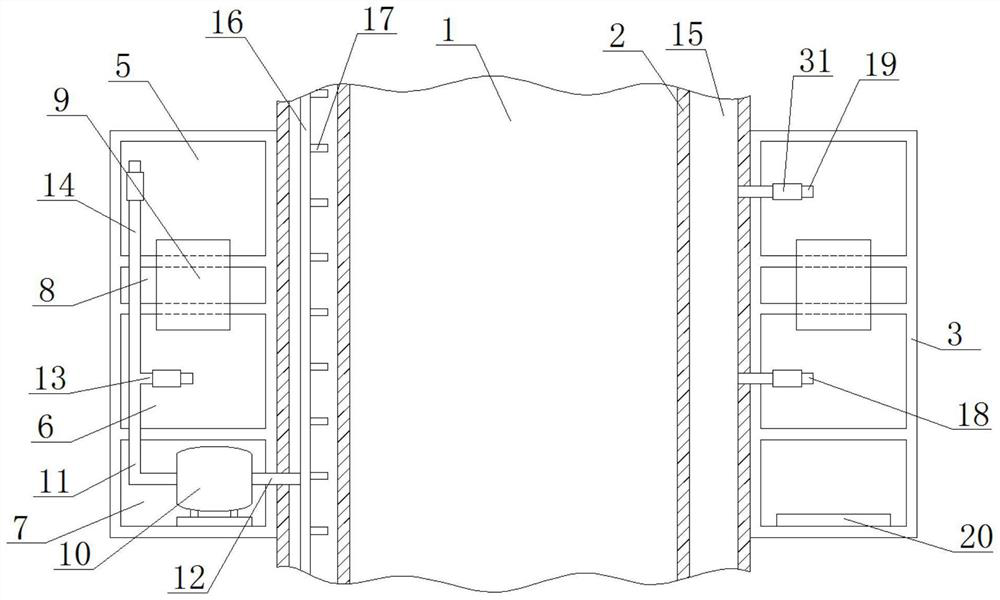

[0028] As a preferred embodiment of the present invention, the quantity of the spray pipe 28 is 2, and the mist sprayed by the two spray pipes 28 can converge at the nozzle of the shower head body 1, so that the nozzle of the shower head body 1 can more fully be softened.

[0029] As a preferred embodiment of the present invention, the annular cold water chamber 5, the annular hot water chamber 6, the constant temperature water chamber 15 and the annular water storage chamber 23 are all filled with clean water, and the clean softening water can prevent the nozzle from being damaged secondary pollution.

[0030] As a preferred embodiment of the present invention, the annular hot water chamber 6 and the annular cold water chamber 5 in the regulating sleeve 3 can continuously deliver hot water or cold water to the constant temperature water chamber 15 in the thermostatic sleeve 2, when When the external ambient temperature is not within the working temperature range of the nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com