Split type pneumatic control button

A split-type, button technology, applied in flushing equipment with water tanks, flushing toilets, water supply devices, etc., can solve the problems of poor reliability, large number of parts, and large use limitations, and achieves strong applicability and simple structure. And compact, easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

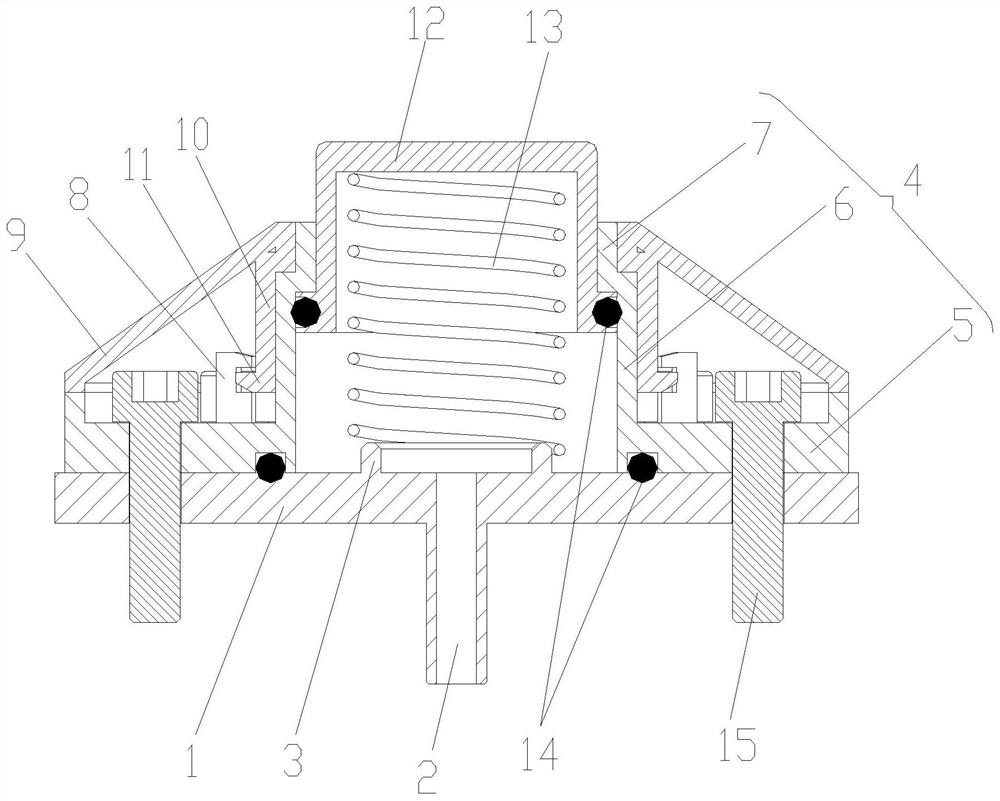

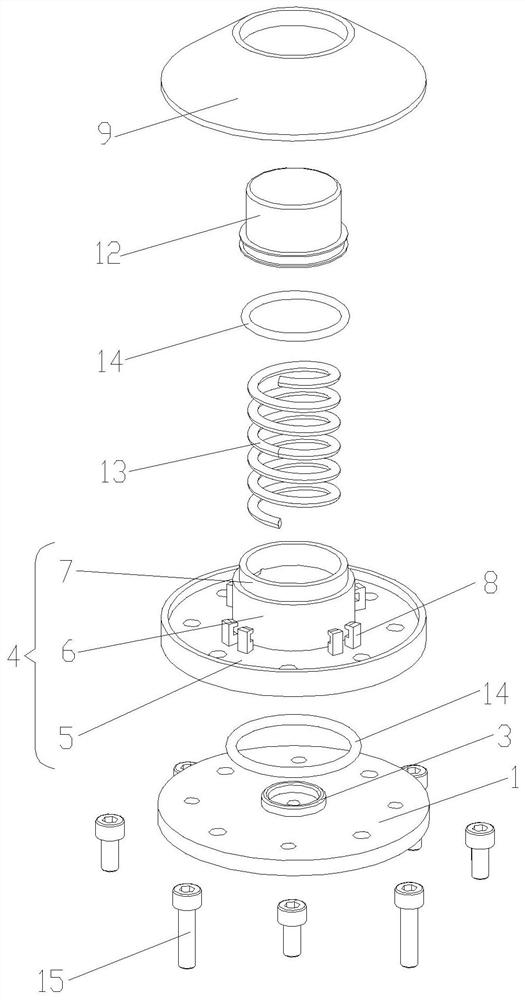

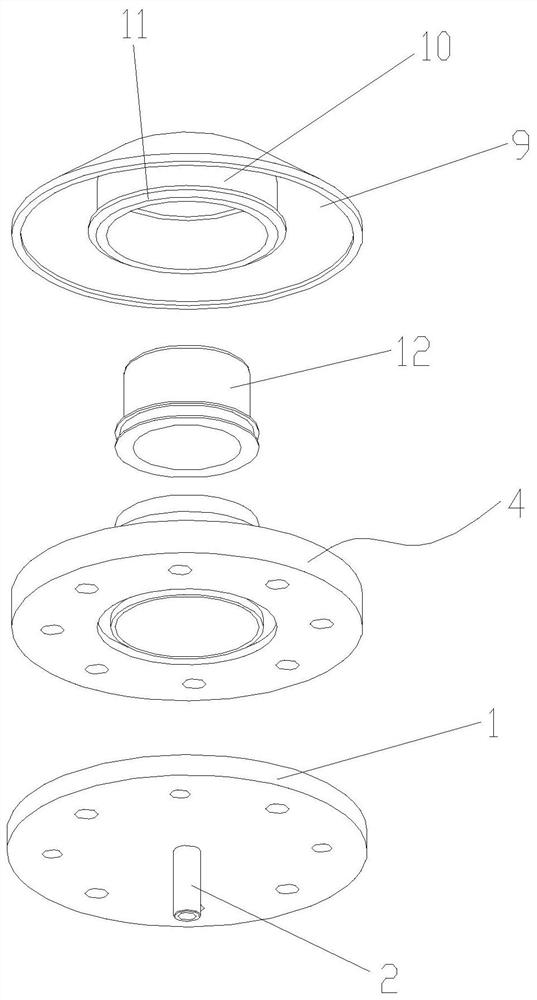

[0032] Such as figure 1, figure 2 As shown, a split-type air control button includes a base 1 fixedly arranged coaxially in sequence, an intermediate housing 4 and an outer shell 9, a button cap 12 nested inside the intermediate housing 4, and the button cap 12 is pressed. And the reset spring 13 for reset; the button cap 12 forms a cavity with the inner wall of the middle housing 4 and the end surface of the base 1, and the middle part of the base 1 has a ventilator connected with the cavity.

[0033] More specifically, the base 1 has a flat columnar structure, with a vent tube 2 extending outwards in the middle and open at both ends, and a stop snap ring 3 at the end opposite to the direction in which the vent tube 2 extends.

[0034] The intermediate housing 4 includes a connection plate 5 and a central sleeve 6 arranged coaxially in an integrated stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com