A rubber shock-absorbing and isolation system for high-rise buildings

A technology of rubber shock absorption and high-rise buildings, which is applied in the direction of buildings, building types, building components, etc., can solve the problems of lack of shock isolation and aggravated sliding, and achieve the effect of increasing longitudinal shock isolation and large vertical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

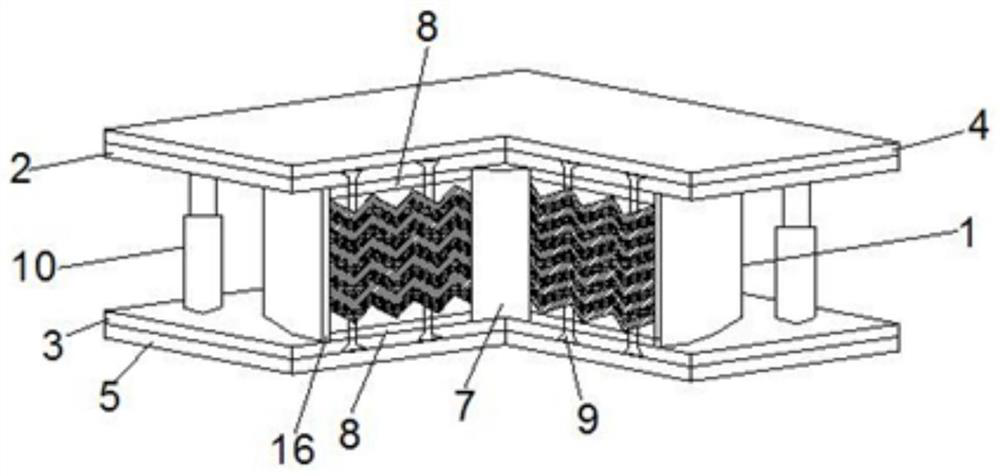

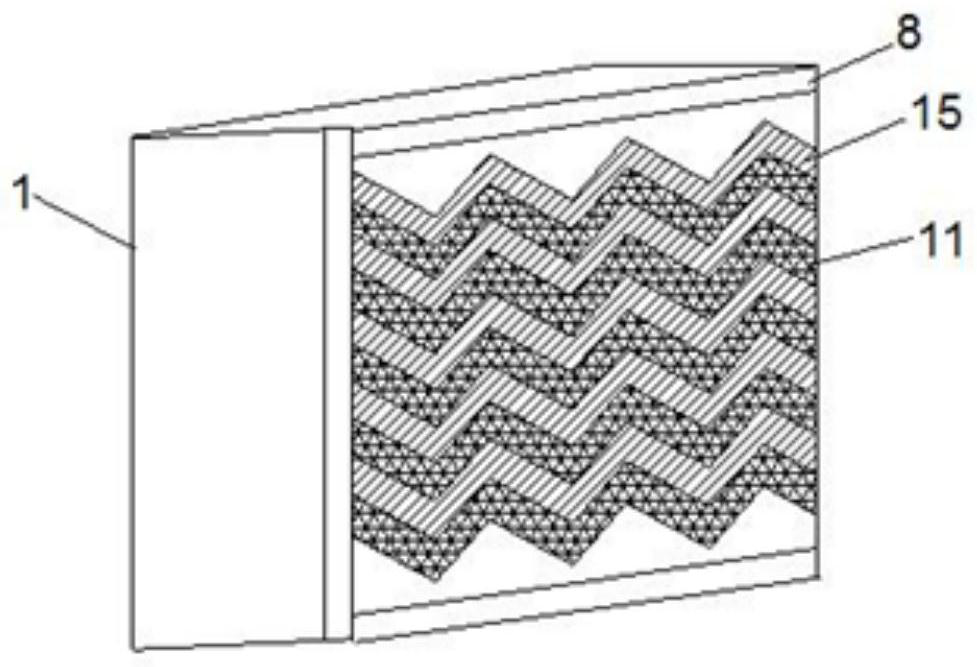

[0048] Such as Figure 1-3 As shown, a rubber shock-absorbing and isolation system for high-rise buildings; comprising, a main shock-absorbing body 1, an upper connecting plate 2, and a lower connecting plate 3; the inside of the main shock-absorbing body 1 is provided with a rubber layer 15 and The steel plate layer 11, the rubber layer 15 and the steel plate layer 11 are superimposed on each other in sequence; the middle position of the rubber layer 15 and the steel plate layer 11 is provided with a lead core 7; the top and bottom of the main shock absorber 1 are connected There is a sealing plate 8, and the top and bottom of the lead core 7 are connected with the sealing plate 8; the outer periphery of the main shock absorbing body 1 is wrapped with a protective layer 16, and the protective layer 16 is made of rubber; A reinforcing rib 9, a plurality of reinforcing ribs 9 run through the rubber layer 15 and the steel plate layer 11; the top of the main shock absorbing body ...

Embodiment 2

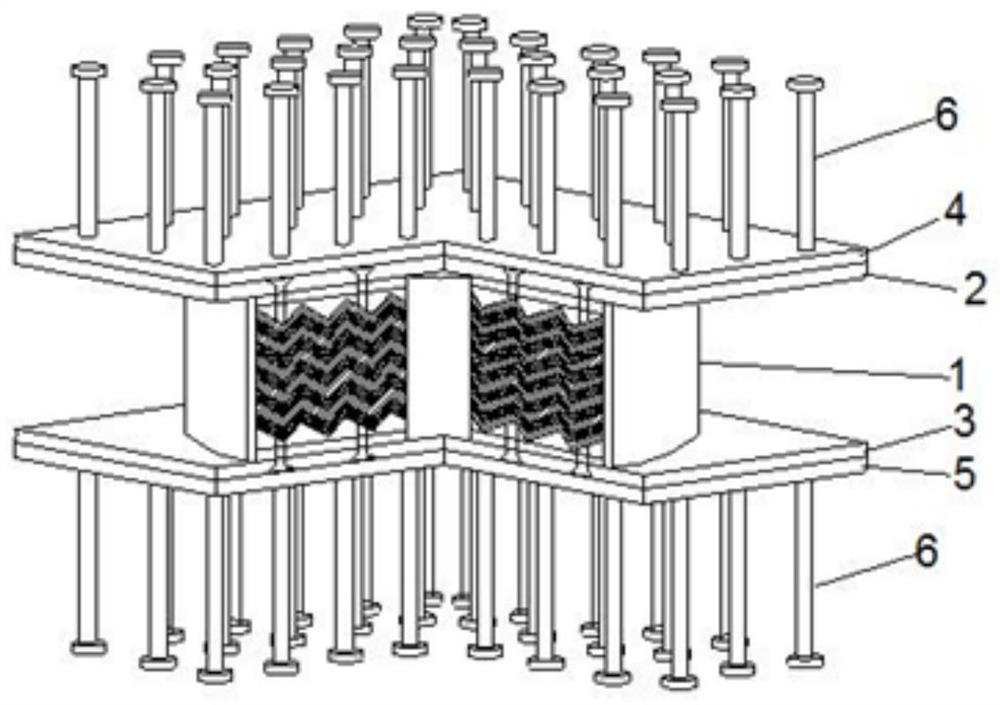

[0051] On the basis of Example 1, as Figure 4-6 As shown, the periphery of the main shock absorber 1 is provided with at least four auxiliary shock absorbers 10, and the four auxiliary shock absorbers 10 are evenly distributed on the periphery of the main shock absorber 1; the barrel of the auxiliary shock absorber 10 The bottom of the body 101 is connected with the lower connecting plate 3, and the other end of the cylinder body 101 is provided with a pillar 102, and the pillar 102 is slidingly connected with the cylinder body 101; the cylinder body 101 is in a sealed structure; One end inside the barrel 101 is connected with a telescopic cylinder 103; the inside of the barrel 101 has an electromagnetic fluid 1032; the telescopic cylinder 103 forms a sliding connection with the inner wall of the barrel 101.

[0052] Two groups of electromagnetic coils 1031 are symmetrically arranged inside the telescopic cylinder 103, and the electromagnetic coils 1031 are connected with wir...

Embodiment 3

[0057] Such as Figure 7-9 As shown, on the basis of the first embodiment, the main shock absorber 1 has a columnar or cuboid structure; the rubber layer 15 and the steel plate layer 11 are superimposed on each other in a wavy structure.

[0058] The outside of the main shock absorber 1 is provided with multiple groups of cables 12, and the cables 12 are arranged between the upper connecting plate 2 and the lower connecting plate 3; the cables 12 are shape memory alloy cables; The four corners of the connecting plate 2 and the lower connecting plate 3 are correspondingly provided with U-shaped hoops 14, and the shape-memory alloy cables form a ring structure on the periphery of the main shock absorber 1 through the U-shaped hoops 14, and the upper The connecting plate 2 and the lower connecting plate 3 are reinforced and connected.

[0059] The upper connecting plate 2 and the lower connecting plate 3 are provided with a plurality of spherical hinges 13 on the peripheral side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com