Composite self-insulation building block and preparation method thereof

A technology of self-insulating blocks and blocks, which is applied in the direction of manufacturing tools, building components, surface layering devices, etc., can solve the problems of poor block forming effect, splashing, and difficult cleaning of foam debris, etc., and achieve the purpose of increasing the forming effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

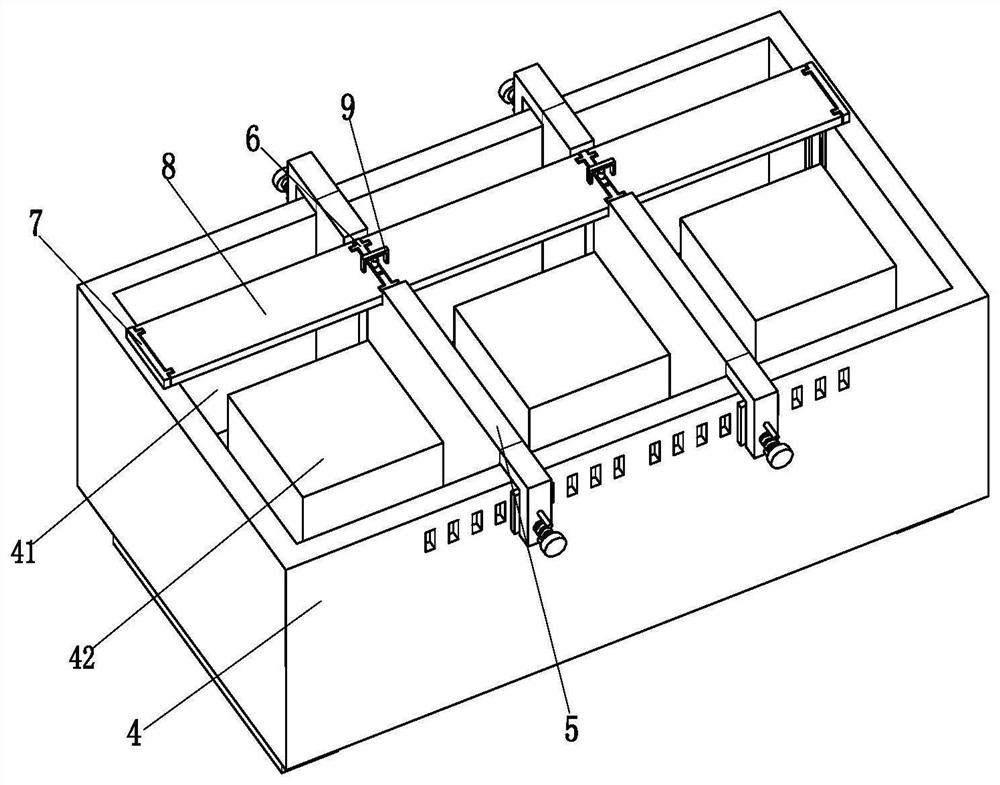

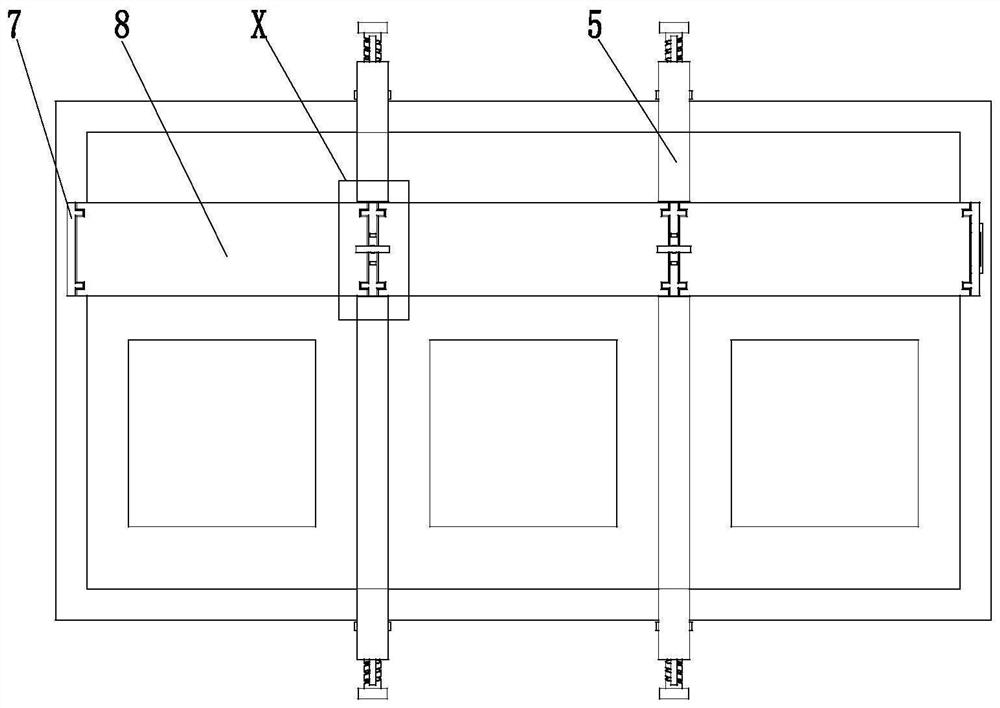

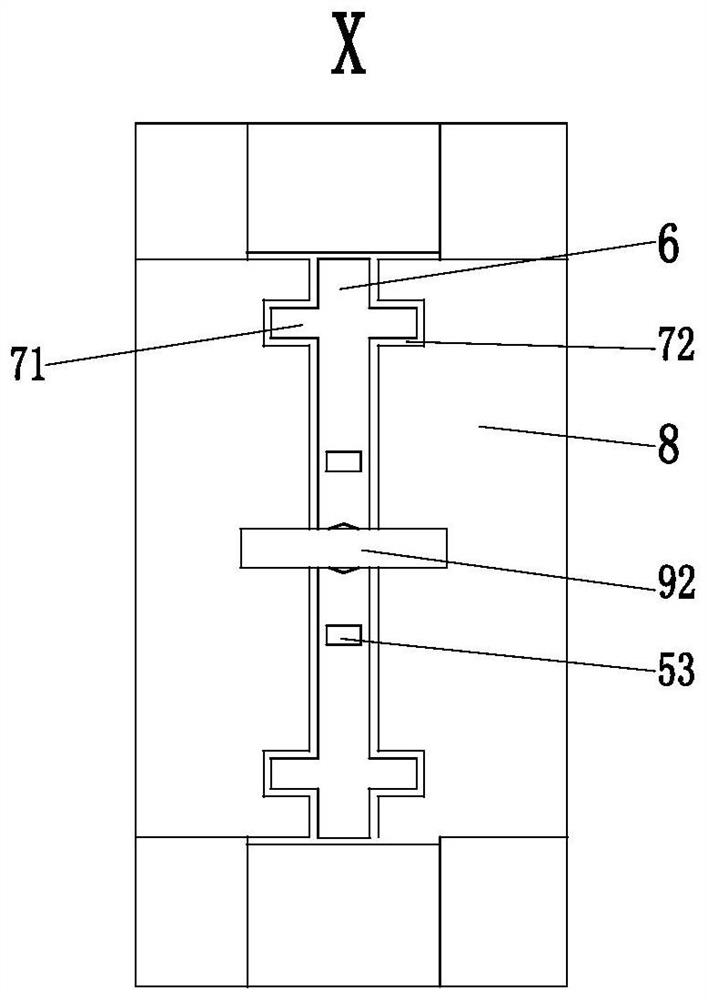

[0035] Such as Figure 1 to Figure 6As shown, a composite self-insulating block includes a block main body 1, a foam layer 2 and a splicing layer 3. The middle part of the block main body 1 is provided with a vertically arranged through groove, and the block main body 1 and the splicing layer 3 are made of concrete, the width of the block body 1 is greater than that of the splicing layer 3, and a foam layer 2 is arranged between the block body 1 and the splicing layer 3, and the foam layer 2 corresponds to the side surfaces of the block body 1 and the splicing layer 3. Dovetail-shaped protrusions are provided, and dovetail grooves matching the dovetail protrusions are provided on the sides of the block body 1 and the splicing layer 3, and arc-shaped...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap