Cup-shaped flexible gear cylinder structure

A technology of flexible splines and cylinders, applied in belts/chains/gears, portable lifting devices, components with teeth, etc., can solve the problems of small stress transition area, complex stress concentration, and no change in wall thickness, etc., to achieve Improve the bearing capacity of flexsplines, improve fatigue resistance, and reduce the effect of stress amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

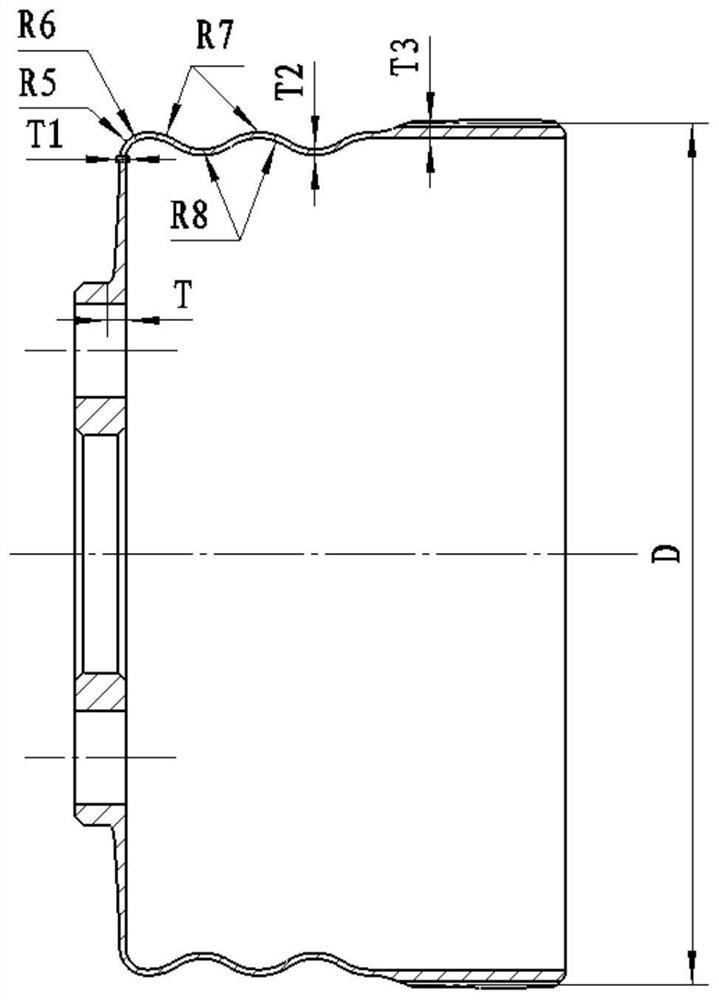

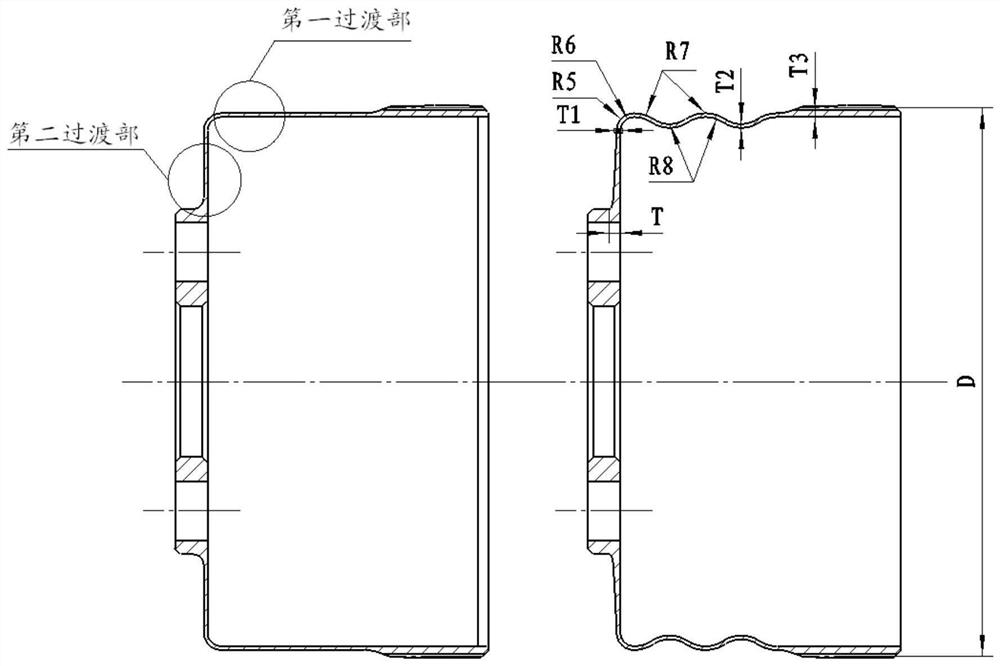

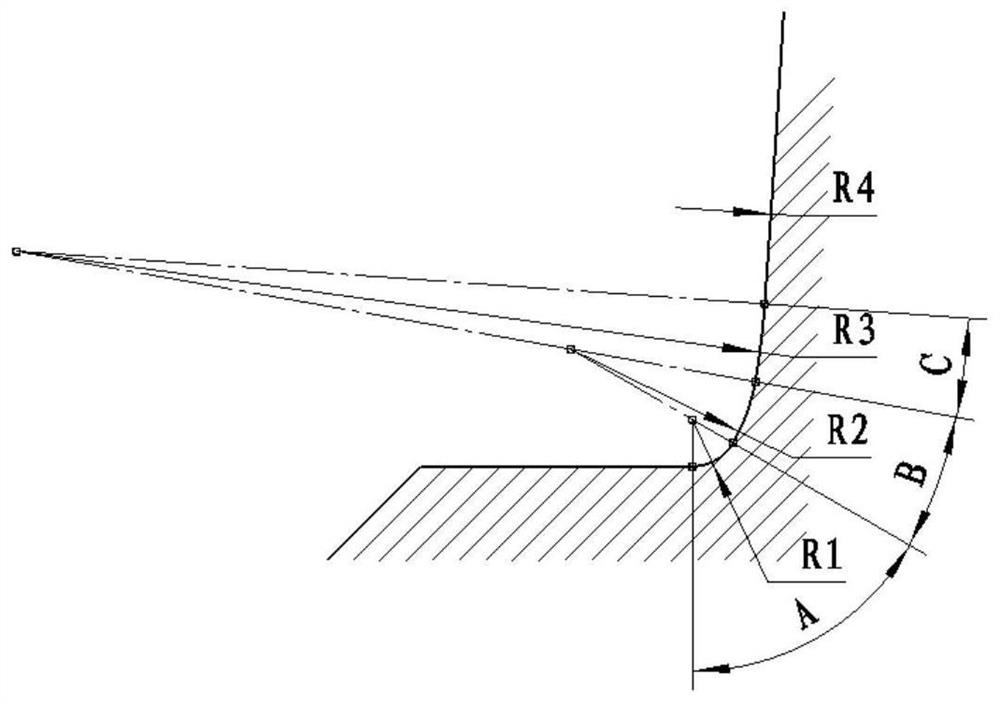

[0042] A cup-shaped flexspline cylinder structure is used to reduce the stress concentration caused by elastic deformation of the flexspline and improve the load-bearing capacity of the flexspline.

[0043] 1) The transition zone of the cylinder adopts a corrugated structure, the outermost diameter of the wave crest is consistent with the maximum outer diameter of the flexspline cylinder, and the wave height is 2 to 4 times the maximum deformation of the cam; figure 1 shown.

[0044] The flexible spline adopts a corrugated structure, that is, 1 wave crest + 2 wave troughs.

[0045] T3=(75+Z R / 4)×D / 10000, where Z is R The number of flexspline teeth, D is the diameter of the pitch circle of the flexspline tooth, and the wall thickness of the T3 flexspline ring gear.

[0046] T2=(0.52~0.55)×T3, T2 is the wall thickness of the cylinder.

[0047] R7-R8=T2, where the crest arc radius R7 and the trough arc radius R8.

[0048] R6=(0.02~0.03)×D.

[0049] R5=(R6+T2)×(0.9~1.0).

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

| Arc radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com