Heat exchanger, heating water circulating unit and control method of heating water circulating unit

A technology for heat exchangers and hot water production, which is used in indirect heat exchangers, heat exchanger types, compressors with reversible cycles, etc. problems such as operating range, to achieve the effect of improving the applicable range of working conditions, eliminating frequent defrosting problems, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

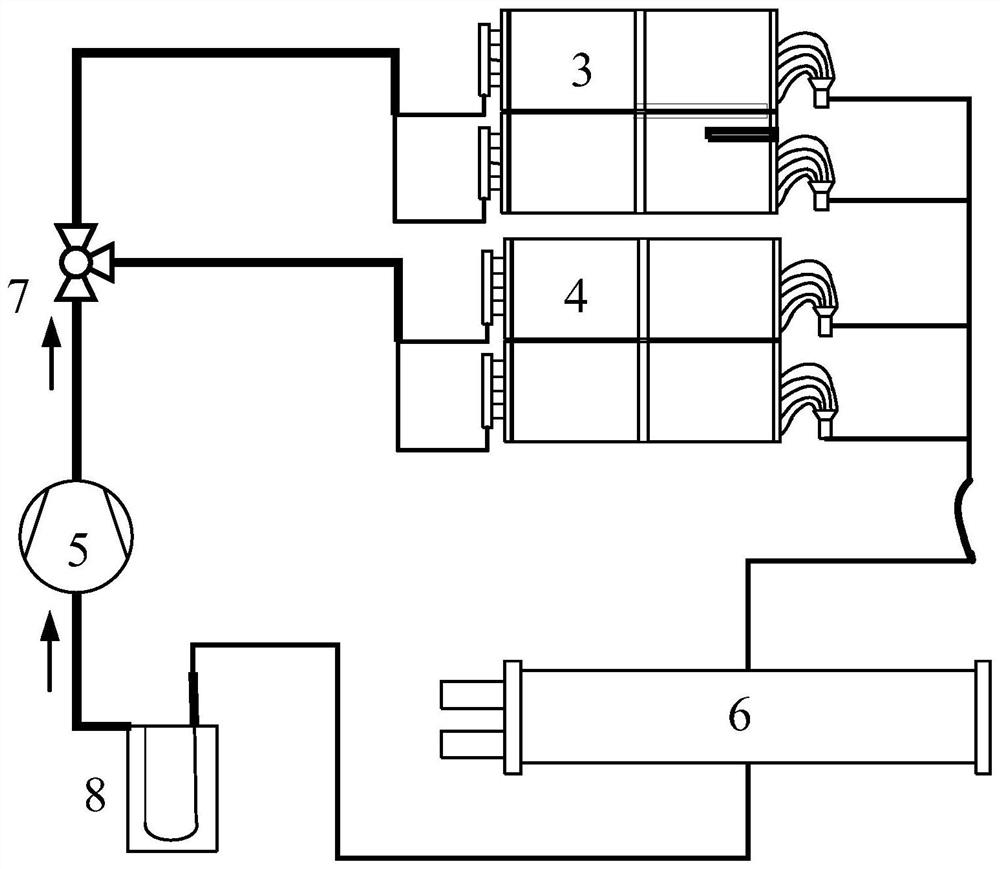

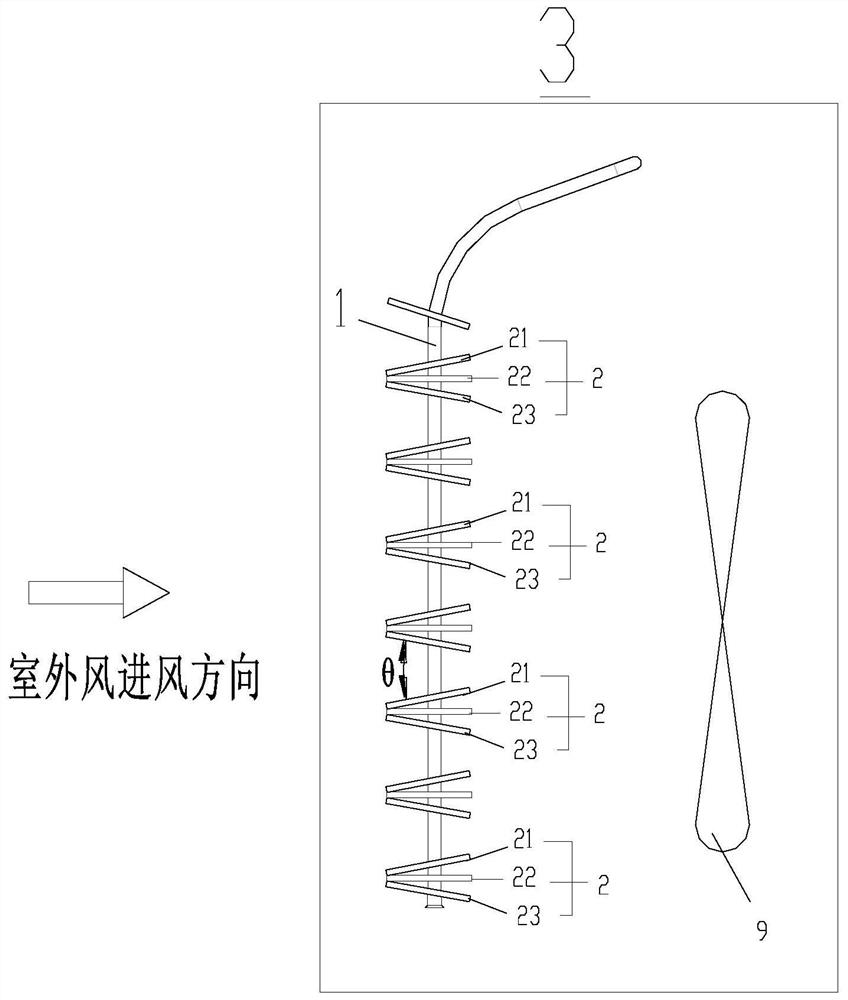

[0045] Such as Figure 1-3 As shown, the present disclosure provides a heat exchanger comprising:

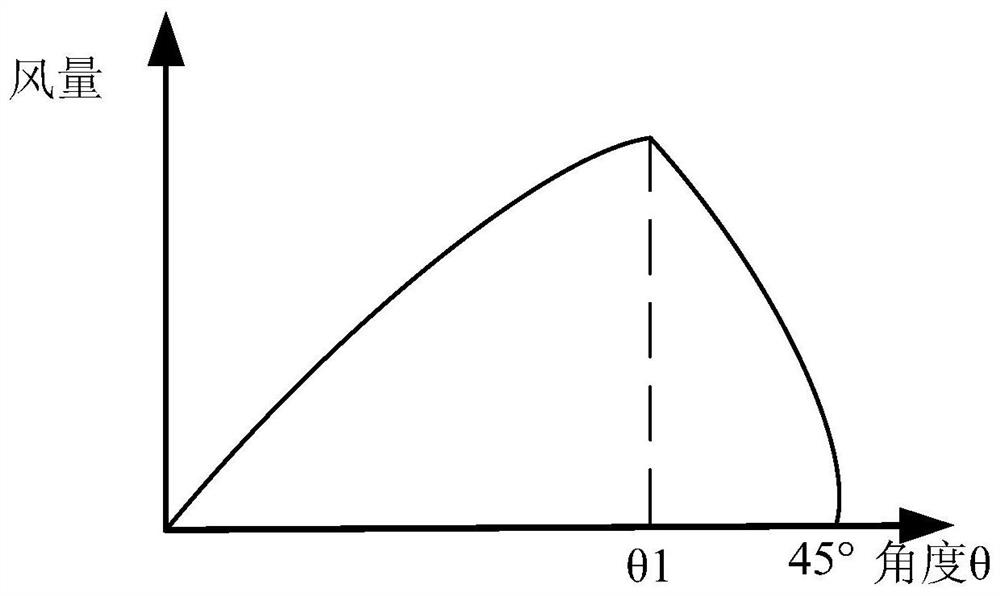

[0046] Heat exchange tubes 1 and heat exchange fins 2, the heat exchange fins 2 are perforated on the heat exchange tubes 1, and the heat exchange fins 2 are at least two, at least two of the heat exchange fins The fins 2 form a group of heat exchange fins; and in two adjacent groups of heat exchange fins, the heat exchange fins in the first group of heat exchange fins that are close to the second group of heat exchange fins , and the heat exchange fins in the second group of heat exchange fin groups that are close to the first group of heat exchange fin groups gradually decrease along the direction of air flow, and the distance is perpendicular to the direction of air flow distance.

[0047] In the present disclosure, at least two heat exchanging fins are arranged as one heat exchanging fin group, and among two adjacent heat exchanging fin groups, the heat exchanging fin grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com