Gun sight

A mirror tube and gun body technology, applied in the field of gun mirrors, can solve the problems of reduced shooting accuracy of shells, shaking of the gun mirror position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

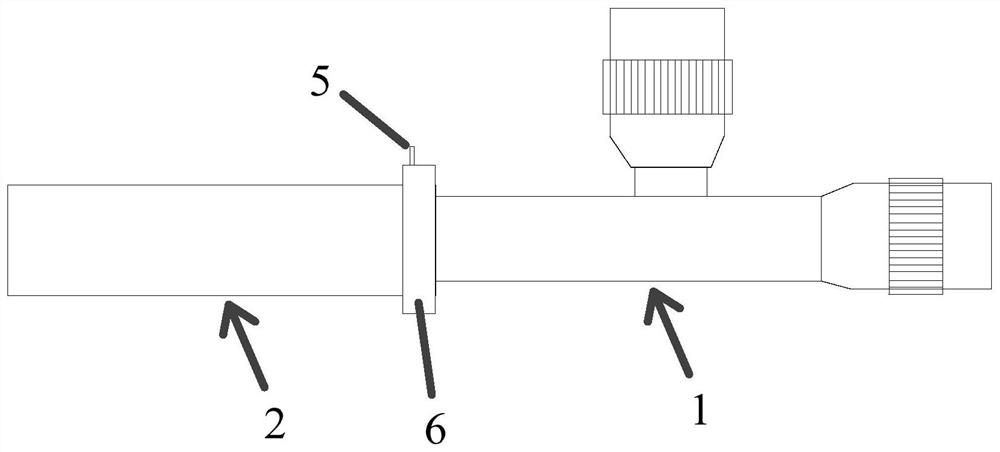

[0042] A gunscope is recorded, such as figure 1 shown, which includes:

[0043] gunscope body 1, used to observe the target;

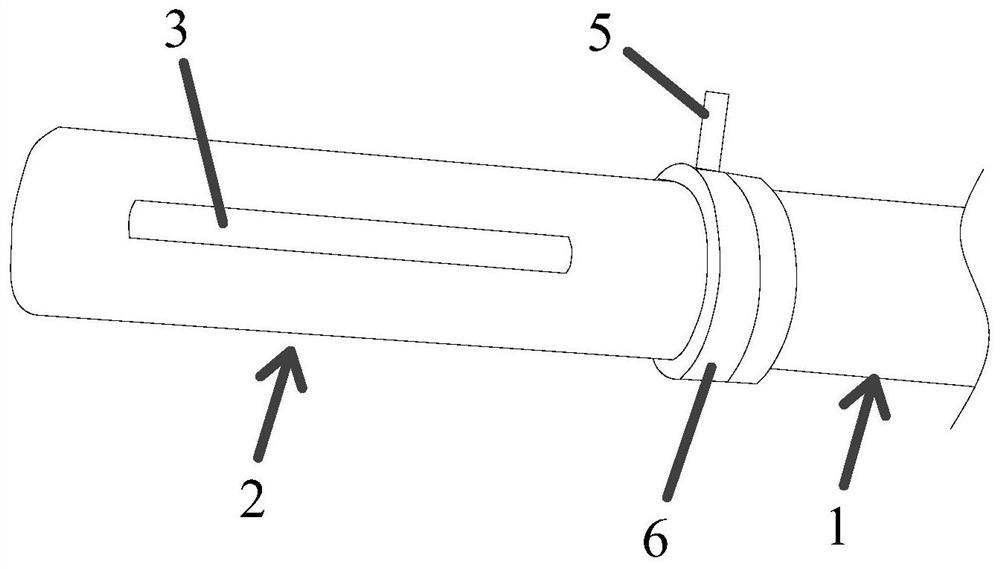

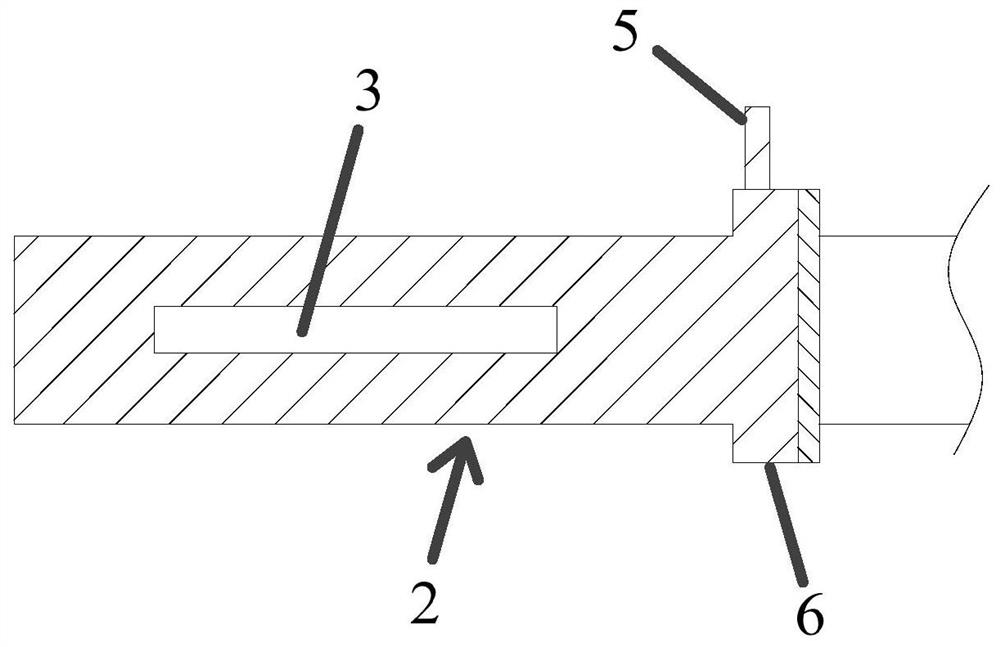

[0044] Connector 2, such as Figure 2 to Figure 4 As shown, the connecting part 2 is connected with the gunscope tube body 1, and is used to fix the gunscope tube body 1 on the gun body; the connecting part 2 is a sealed tubular cavity, and the connecting part 2. Three openings 3 are uniformly arranged in the circumferential direction;

[0045] The opening 3 in this embodiment is a bar-shaped opening arranged along the length direction of the connecting portion 2 . And the three openings 3 are evenly distributed in the circumferential direction of the connecting portion 2;

[0046] Elastic expansion membrane 4, the elastic expansion membrane 4 is a rubber membrane, and the rubber membrane is attached and arranged in the connecting part 2; when the inner cavity of the connecting part 2 is inflated, the elastic expansion membrane 4 is released from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com