Roller curvature measuring device

A measuring device and bending technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of scratches, affecting the quality of glass plates, time-consuming and labor-consuming, etc., to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solution of the application, the application will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the application. .

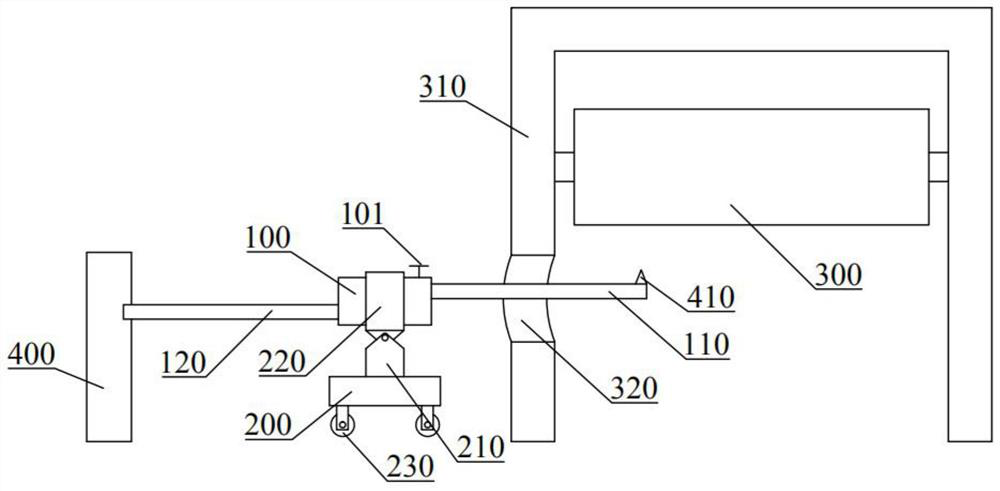

[0019] Please refer to figure 1 , the present embodiment provides a roll bending measurement device, including a telescopic assembly and a moving assembly; The rods 120 are respectively provided with slide rails along the length direction, and the sleeve 100 is provided with slide blocks correspondingly.

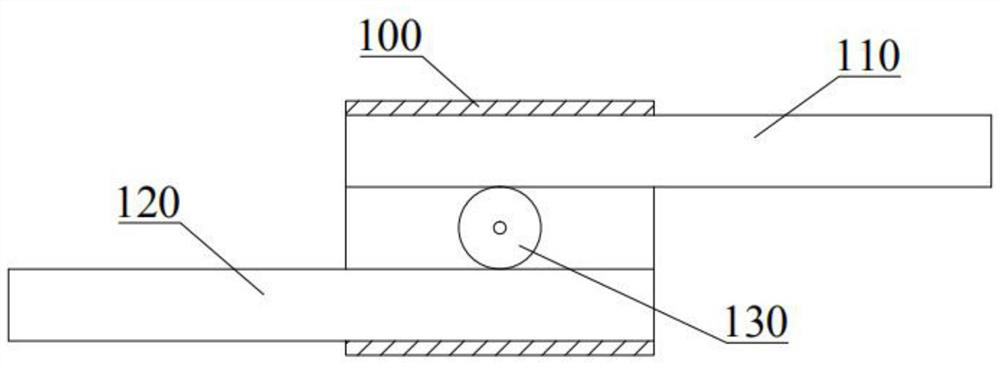

[0020] Please refer further figure 2 , in a preferred embodiment, a relatively rotatable gear 130 is also provided in the sleeve 100; the gear 130 is located between the upper sliding bar 110 and the lower bar 120; There are matching butt teeth; therefore, the linkage between the upper sliding rod 110 and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com