High-compression-resistance cable

A cable and wire core technology, applied in the field of high-pressure-resistant cables, can solve the problems of abnormal use, damaged conductors, and inability to buffer and protect the insulating sleeve, and achieve the effect of high structural strength and buffering of external pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

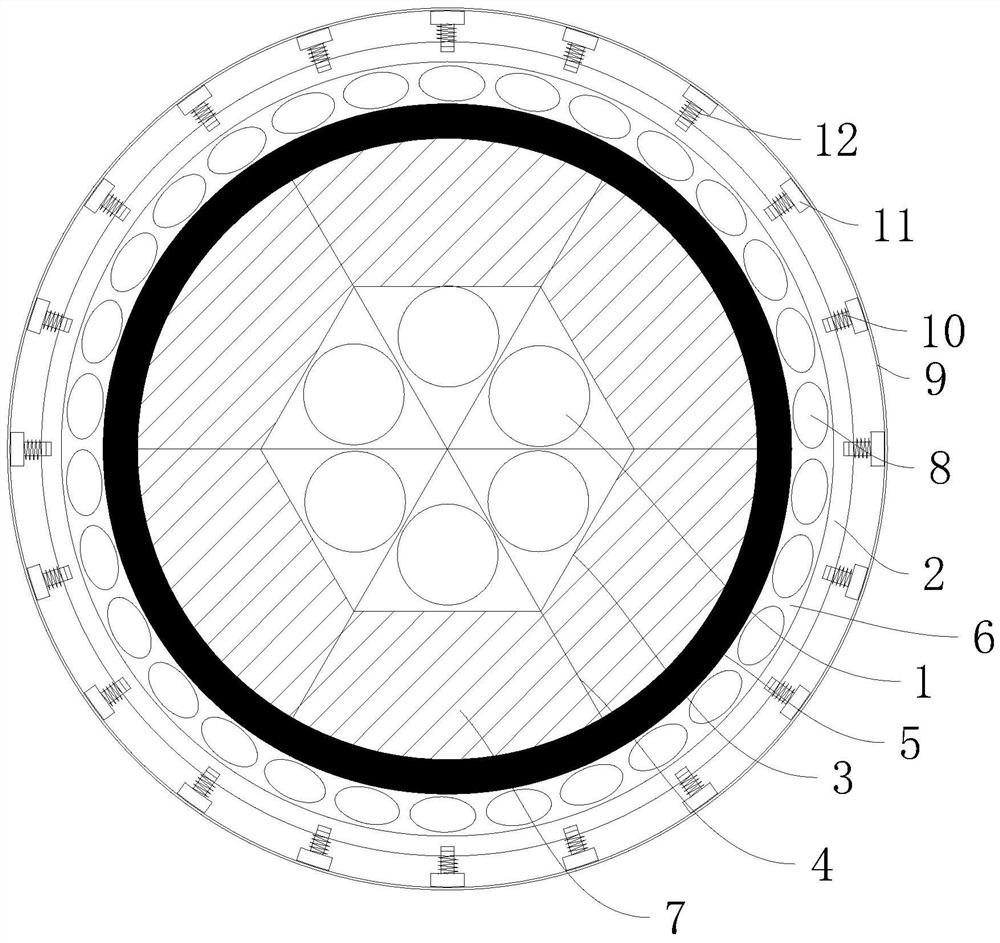

[0021] see figure 1 , the present invention provides a high-pressure-resistant cable, which includes a core 1 and an insulating layer 2 wrapped outside the core 1. The core 1 is arranged in a protective shell 3. The protective shell 3 has a hexagonal structure and is divided into A plurality of uniform accommodation spaces, a wire core 1 is installed in the accommodation space, a buffer elastic layer 4 is arranged on the outer peripheral surface of the protective shell 3, a cotton braided protective layer 5 is arranged on the outer peripheral surface of the buffer elastic layer 4, and the insulating layer 2 and the cotton braided protective layer An airbag protective layer 6 is arranged between the 5, and an elastic protective layer 9 is arranged on the outer peripheral surface of the insulating layer 2.

[0022] A shock-absorbing assembly is arranged between the insulating layer 2 and the elastic protection layer 9. The shock-absorbing assembly includes: a top column 10, a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com