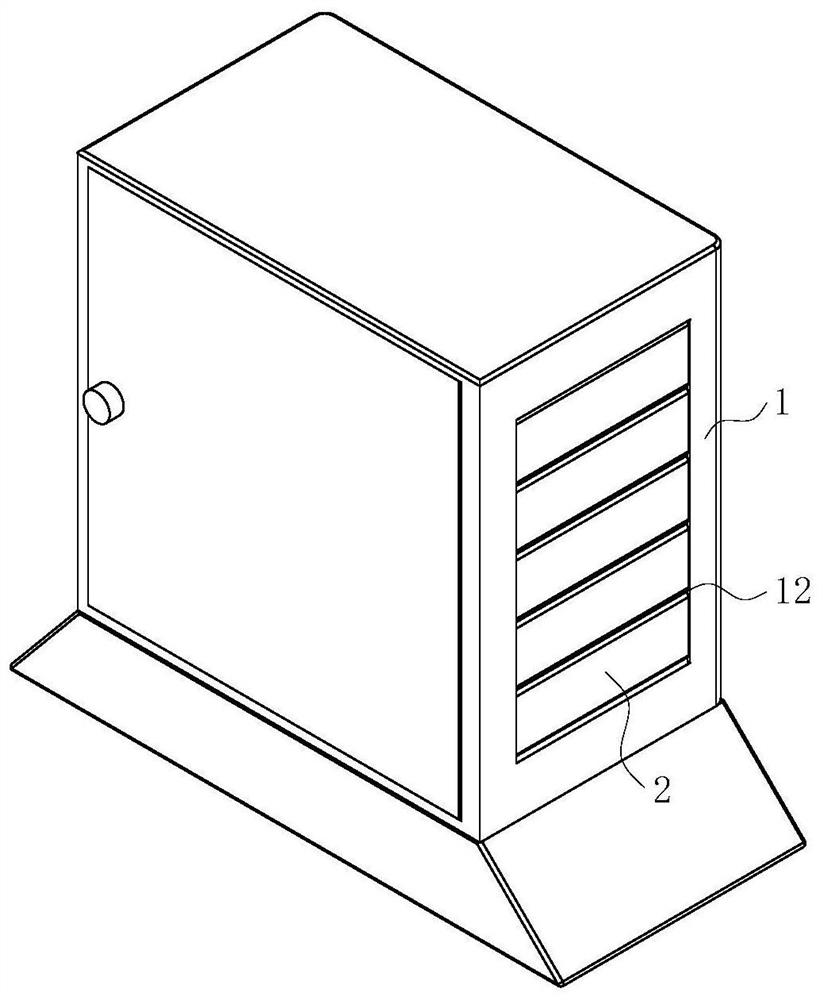

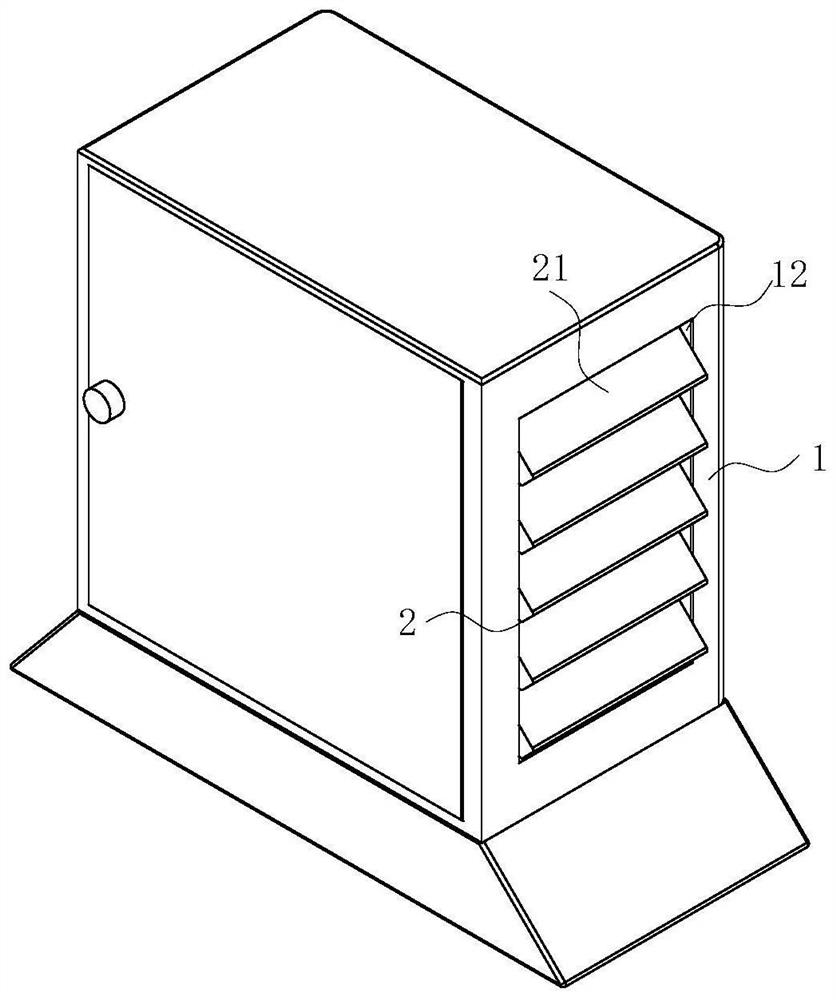

High-voltage power distribution cabinet safety protection method

A high-voltage power distribution cabinet and safety protection technology, which is applied in the substation/distribution device shell, electrical components, substation/switch layout details, etc. It is difficult to make full use of cold air for safe cooling and other issues to achieve the effect of improving safe and stable heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

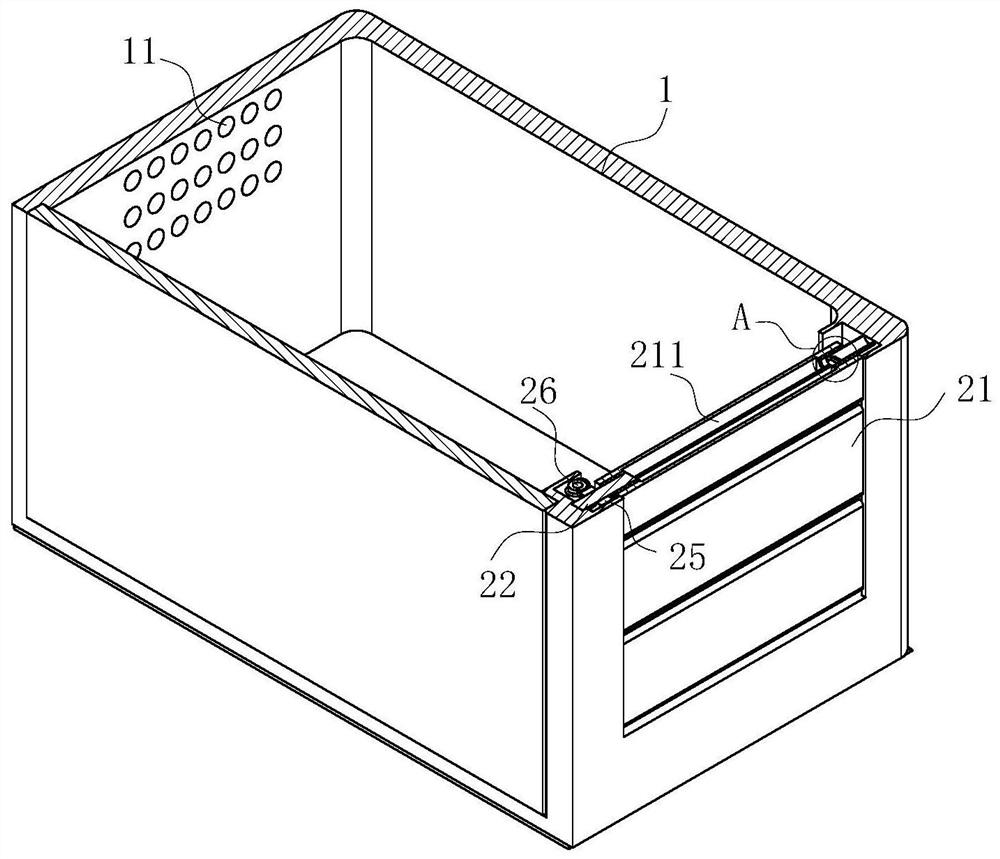

[0045] As an embodiment of the present invention, a sealing disk 3 is fixed inside the rotating conduit 23, and an air guide hole 31 is opened at a non-center position of the sealing disk 3; And the non-center position of the fitting disk 4 is provided with an exhaust groove 41; the fitting disk 4 and the sealing disk 3 are rotated and fitted; the exhaust groove 41 is rotated and aligned with the air guide hole 31; during work, when the rotating column 22 drives the fan blade plate 21 to rotate to the vertical state, and at this time the fan blade plate 21 will drive the rotating guide tube 23 to rotate, so that the air guide hole 31 on the inner sealing disc 3 of the rotating guide tube 23 and the end of the air guide tube 24 fit on the disc 4 The exhaust grooves 41 are aligned, and then the cooling gas in the air duct 24 will enter the cooling chamber 211 through the air guide holes 31 and the exhaust grooves 41, and then the cooling chamber 211 can be cooled; when the fan bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com