Four-degree-of-freedom fixing support for lung puncture operation in hospital

A technology with fixed support and degrees of freedom, applied in the direction of puncture needles, stereotaxic surgical instruments, applications, etc., can solve problems such as accurate positioning errors, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings and embodiments.

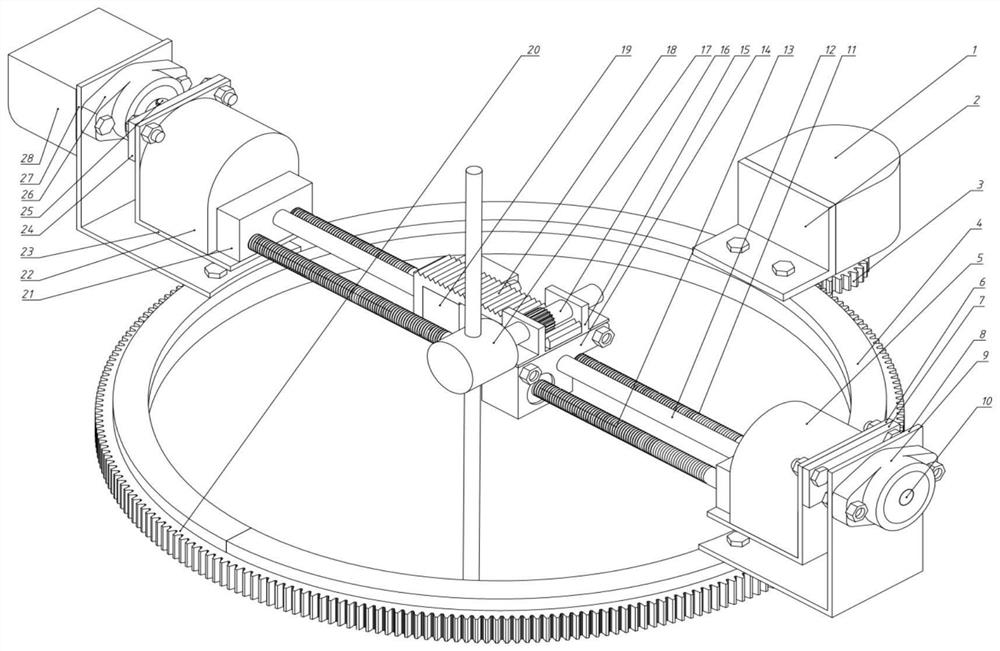

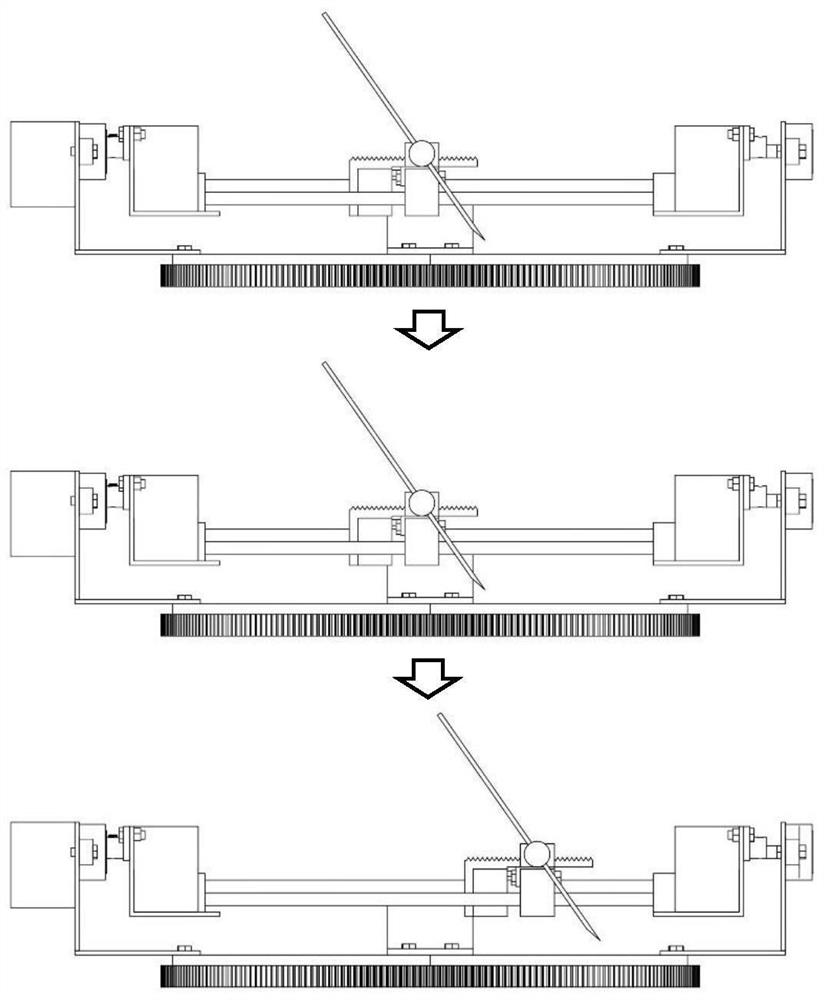

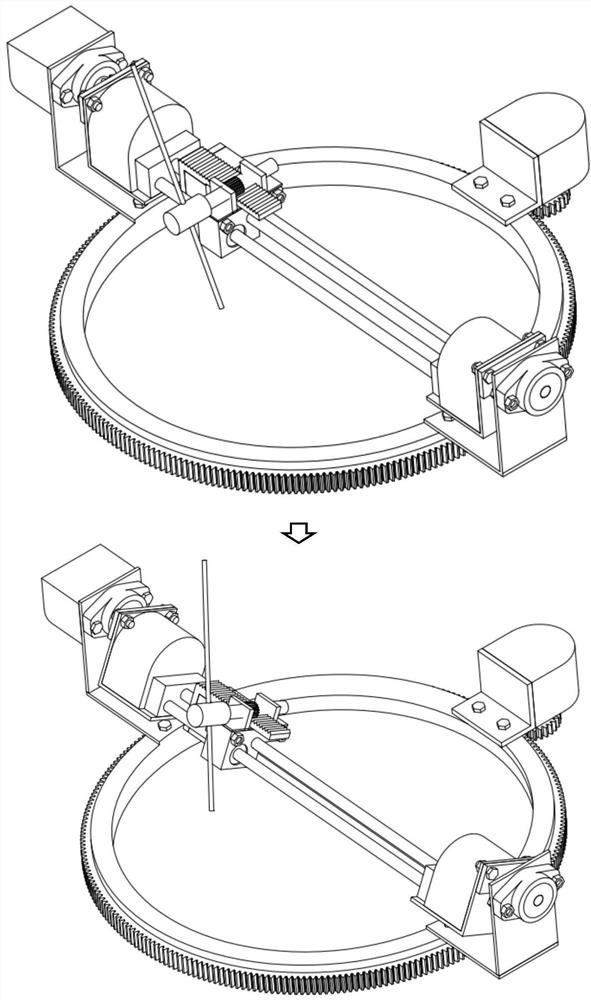

[0025] The specific implementation is as figure 1 As shown, it includes a circular support seat, a rotatable linear guide rail and a puncture needle cover set 17.

[0026]The arc-shaped support includes a drive motor A1, an L-shaped motor seat 2, a pinion 3, two semi-arc sliders 4, and an outer gear ring 20 with a guide rail; the outer gear ring 20 with a guide rail is fixed, and the outer gear ring 20 with a guide rail The outer peripheral side is an outer gear ring structure, and the top surface is provided with an arc-shaped boss. Two semi-arc-shaped sliders 4 form an integral arc-shaped slider. The semi-arc-shaped slider 4 is embedded on the arc-shaped boss and Rotate along the circumference of the arc-shaped boss, so that the semi-arc-shaped slider 4 and the outer gear ring with guide rail form a rotating pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com