Automatic tallying and sorting logistics system and method for various materials

A logistics system and tally technology, applied in the direction of sorting, etc., can solve the problems of low order completion efficiency, low work efficiency, and a lot of time spent by sorting personnel, so as to achieve high synchronization and collaborative operation efficiency, and improve equipment Occupation rate, the effect of meeting the continuous sorting work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

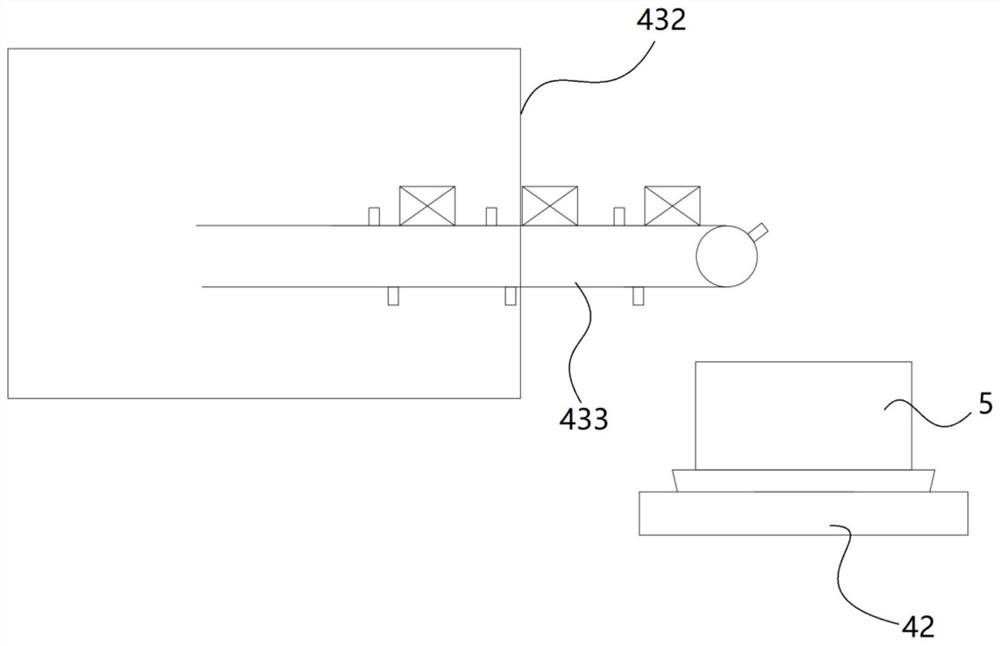

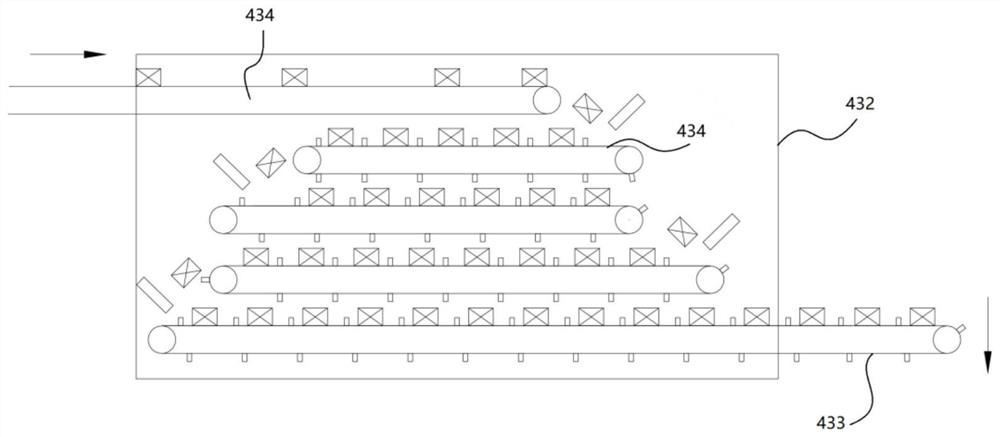

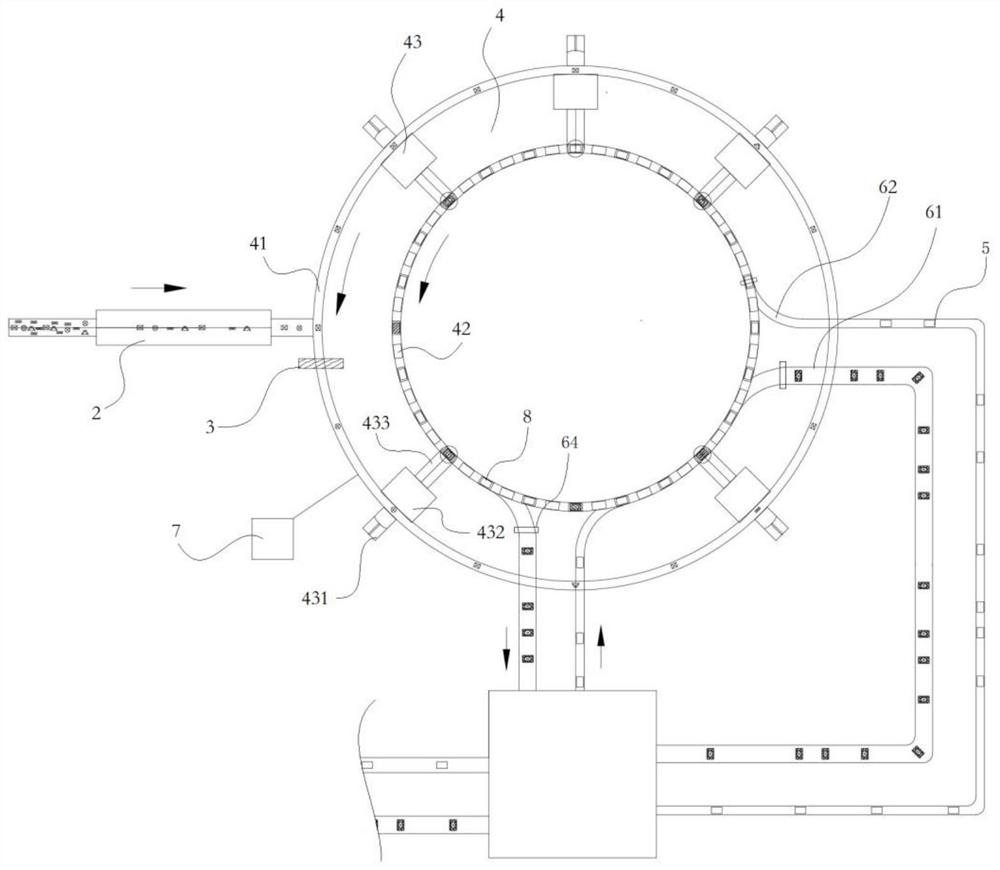

[0019] Embodiment 1: An automated tallying and sorting logistics system for various materials, including a feed conveying mechanism 2, a cargo identification mechanism 3, a sorting device 4, a cargo box 5, a box-in mechanism, a delivery mechanism and a controller 7, The sorting device 4 includes: an outer loop conveyor belt 41 and an inner loop conveyor belt 42 distributed in an inner and outer double loop, the feeding conveyor mechanism 2 is connected to the outer loop conveyor belt 41 for feeding, and the outer loop conveyor belt 41 is located at the feeding place A cargo identification mechanism 3 connected to the controller 7 is provided, and the outer loop conveyor belt 41 and the inner loop conveyor belt 42 are connected through several sorting cargo buffer sorting devices 43, and the cargo box 5 can be connected to the inner loop conveyor belt. 42 moves accordingly and realizes entry and exit from the box entry mechanism and the delivery mechanism; the sorting goods buff...

Embodiment 2

[0027] Embodiment 2: the automatic tallying and sorting method of multiple materials, such as Figure 6 , 7 as shown,

[0028] Step S1, put the materials into the outer ring conveyor belt 41 one by one on the feeding conveying mechanism 2, and perform machine vision recognition for each single product put in to identify its type information, and record the single product synchronously The input time point information of the input time point information, and the category information and time point information are sent to the controller 7; that is, when tallying, the machine vision will generate a sorting tally task every time the category information of a commodity is successfully recognized. If the recognition is unsuccessful, The push rod device of the error correction and rejection equipment pushes it down the outer ring conveyor belt 41, and then waits for the follow-up to refill the feeding conveyor mechanism 2;

[0029] Step S2, after the controller 7 receives the type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com