Epoxy resin and glass fiber composite material composition and high-frequency copper-clad plate manufactured by same

A glass fiber and epoxy resin technology, applied in synthetic resin layered products, glass/slag layered products, coatings, etc., can solve the problems of large dielectric loss, slow transmission rate, low stability, etc. Small electrical loss, improved stability, and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

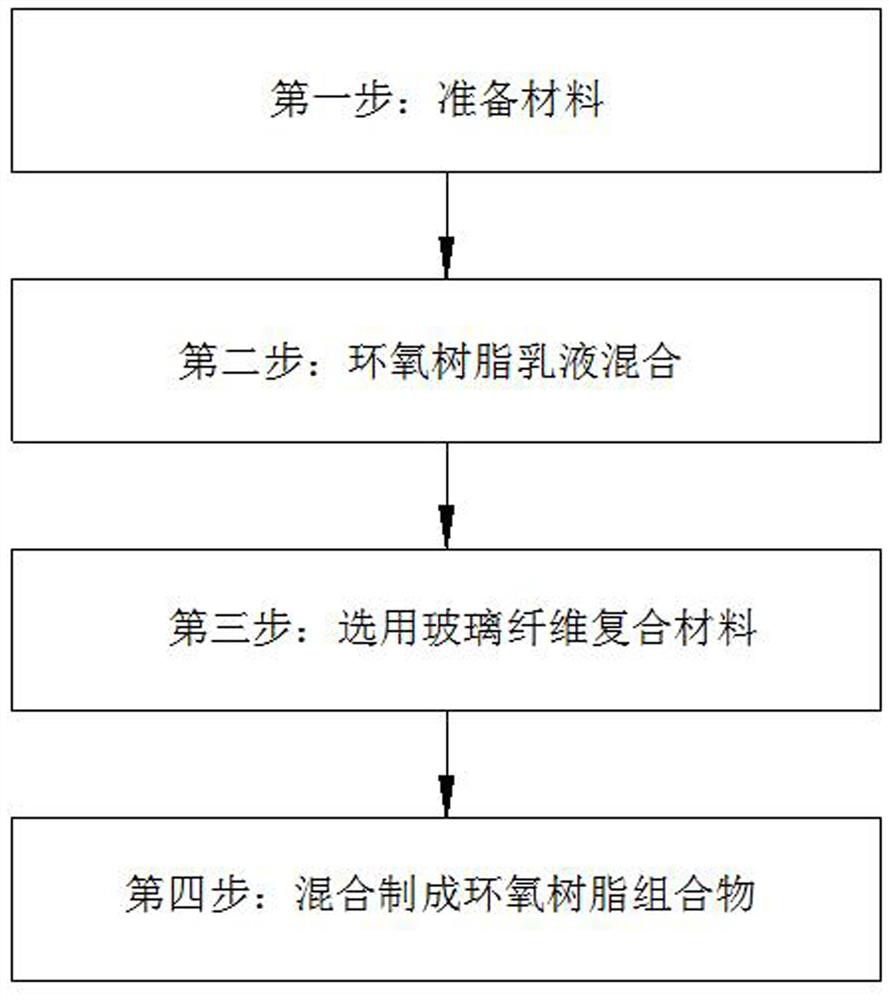

[0040] Embodiment 1: The epoxy resin and glass fiber composite material composition proposed by the present invention and the high-frequency copper-clad laminate manufactured therewith, the preparation process of the high-frequency copper-clad laminate is as follows:

[0041] Step 1: Epoxy resin emulsion and glass fiber composite material are mixed to form a composition, and stirred evenly with a conventional stirring rod;

[0042] The second step: using the above composition and 0.042mm electronic grade glass cloth to prepare a rubber-impregnated sheet with a thickness of 0.08mm and a dielectric constant of 6.2;

[0043] Step 3: The above composition and copper foil are sequentially dried, baked, and sintered. The sintering temperature is controlled between 320-360 degrees Celsius, and the baking time is controlled within 10-20 minutes;

[0044] Step 4: Laminate the ready-to-use copper foil and dipped cloth into a high-frequency copper clad laminate in the form of copper foil...

Embodiment 2

[0045] Embodiment 2: The epoxy resin and glass fiber composite material composition proposed by the present invention and the high-frequency copper-clad laminate manufactured therewith, the preparation process of the high-frequency copper-clad laminate is as follows:

[0046] Step 1: Epoxy resin emulsion and glass fiber composite material are mixed to form a composition, and stirred evenly with a conventional stirring rod;

[0047] The second step: using the above composition and 0.046mm electronic grade glass cloth to prepare a rubber-impregnated sheet with a thickness of 0.08mm and a dielectric constant of 6.2;

[0048] Step 3: The above composition and copper foil are sequentially dried, baked, and sintered. The sintering temperature is controlled between 320-360 degrees Celsius, and the baking time is controlled within 10-20 minutes;

[0049] Step 4: Laminate the ready-to-use copper foil and dipped cloth into a high-frequency copper-clad laminate according to the method of...

Embodiment 3

[0050] Embodiment 3: The epoxy resin and glass fiber composite material composition proposed by the present invention and the high-frequency copper-clad laminate manufactured therewith, the preparation process of the high-frequency copper-clad laminate is as follows:

[0051] Step 1: Epoxy resin emulsion and glass fiber composite material are mixed to make a composition, and stirred evenly by means of an ultrasonic oscillator and a conventional stirring rod;

[0052]The second step: using the above composition and 0.042mm electronic grade glass cloth to prepare a rubber-impregnated sheet with a thickness of 0.08mm and a dielectric constant of 6.2;

[0053] Step 3: The above composition and copper foil are sequentially dried, baked, and sintered. The sintering temperature is controlled between 320-360 degrees Celsius, and the baking time is controlled within 10-20 minutes;

[0054] Step 4: Laminate the ready-to-use copper foil and dipped cloth into a high-frequency copper-clad ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap