Hollow cable sleeve clamp and tension test equipment

A technology for tension testing and cable sheathing, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., and can solve the problem of damage to hollow cable sheaths, inconvenient use by staff, and difficult side-view parameters, etc. problem, to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

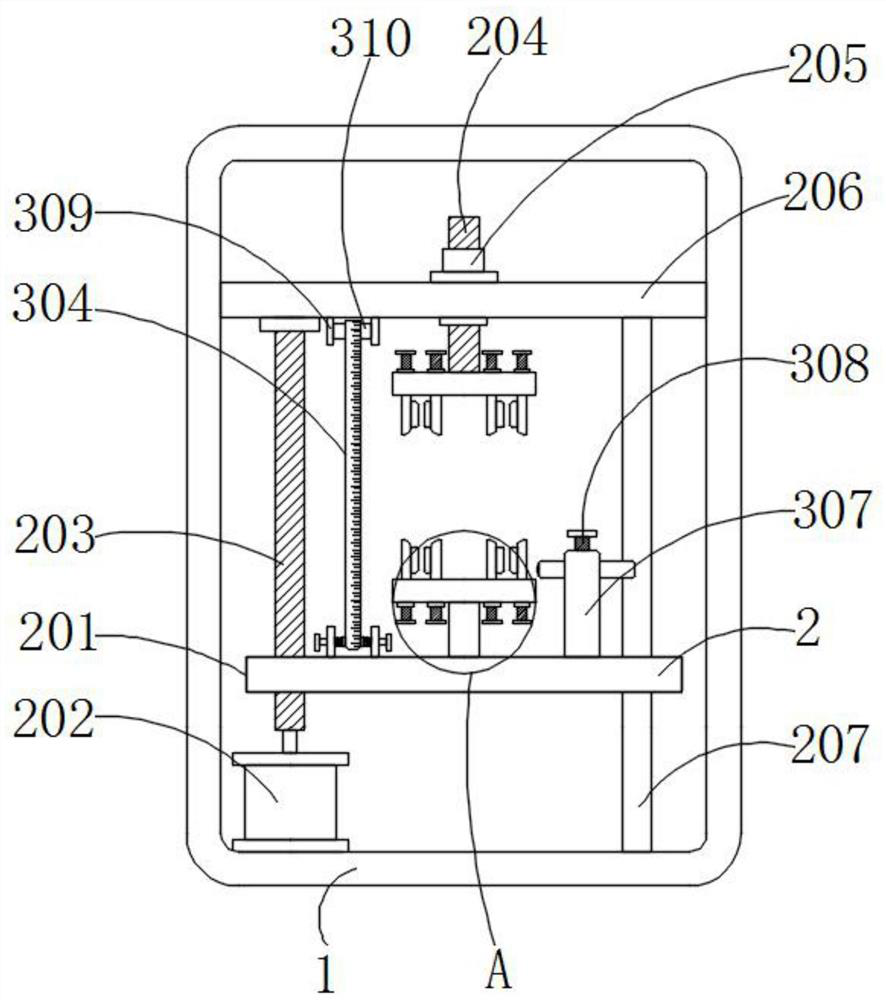

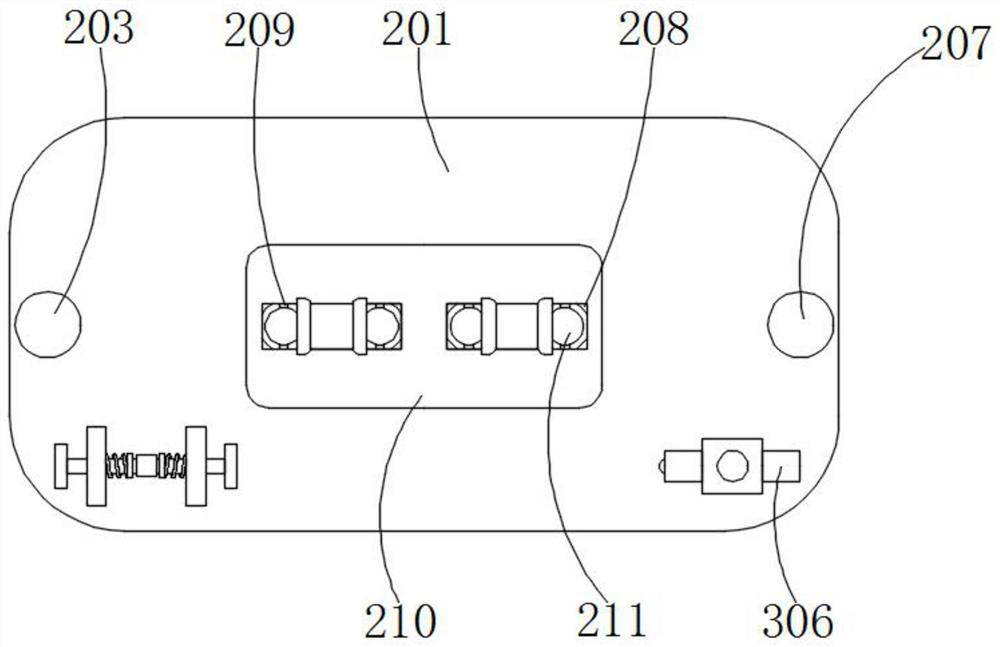

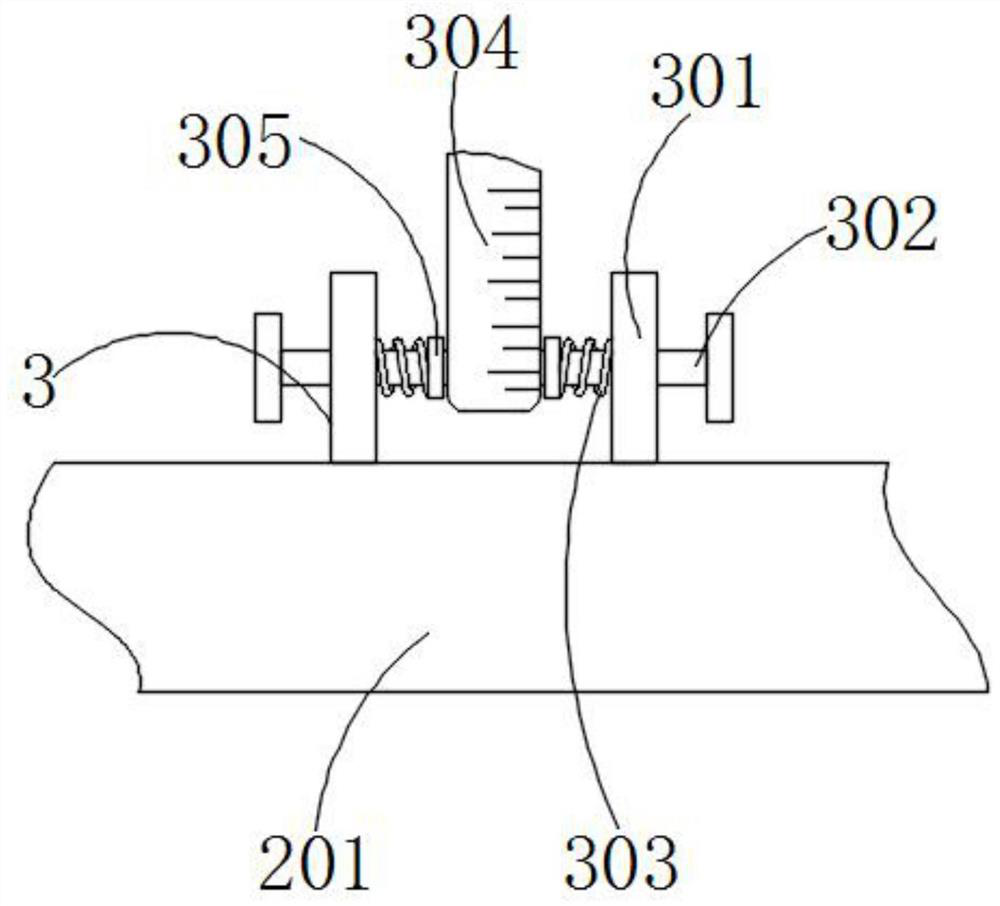

[0025] Example 1, such as Figure 1-4 As shown, the present invention provides a hollow cable sheath fixture and tensile testing equipment, including a box body 1 , a clamping mechanism 2 is arranged inside the box body 1 , and a measuring mechanism 3 is arranged inside the clamping mechanism 2 .

[0026] Let's talk about the specific settings and functions of the clamping mechanism 2 and the measuring mechanism 3 in detail.

[0027] Such as figure 1 , figure 2 with Figure 4 As shown, the clamping mechanism 2 includes a DC motor 202, the output shaft at the top of the DC motor 202 is fixedly connected with a first threaded rod 203, and the outer surface of the first threaded rod 203 is threaded with an operation panel 201, and the operation panel 201 is close to the left side The inner slide of the first threaded rod 203 is embedded with a limit rod 207, the top of the first threaded rod 203 is fixedly connected with a fixed plate 206 through a bearing, and the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com