A super high resolution miniature projection lens

An ultra-high-resolution, micro-projection technology, applied in instruments, projection devices, optics, etc., can solve the problem that the micro-projection lens cannot reach high resolution, achieve good correction of chromatic aberration, uniform illumination, and reduce beam height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

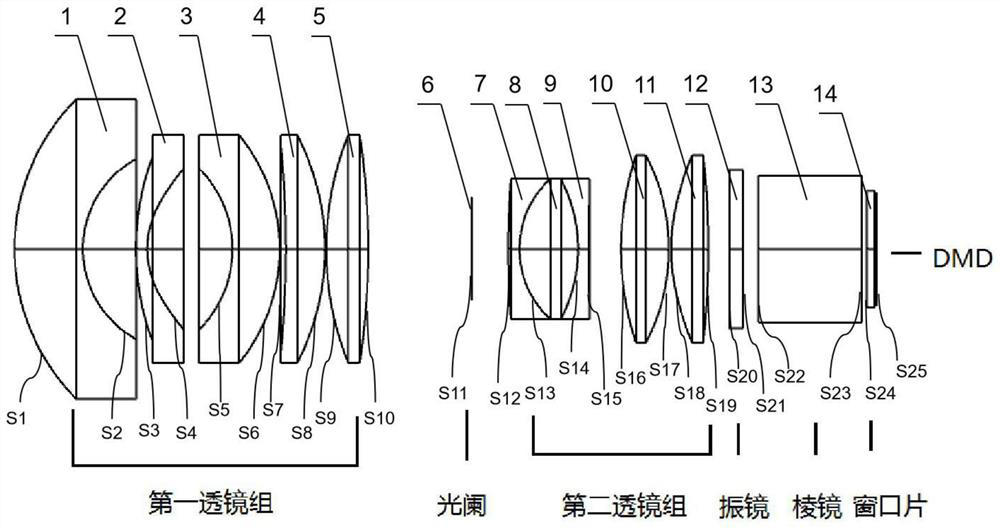

[0040] see figure 1 , figure 1 The optical structure diagram of the micro-projection lens provided by the application example of the present invention; the present invention provides an ultra-high-resolution micro-projection lens, the lens comprises: a first lens group with a positive focal length, a diaphragm 6, A second lens group with a positive focal length, a galvanometer 12, a prism 13, a window 14 and a DMD; wherein the first lens group includes, the first lens 1 is a glass spherical lens, the second lens 2 is a plastic aspherical lens, and the third The lens 3 is a glass spherical lens, the fourth lens 4 is a glass spherical lens, and the fifth lens 5 is a glass spherical lens; wherein the second lens group includes, the sixth lens 7 is a glass spherical lens, the seventh lens 8 is a glass spherical lens, The eighth lens 9 is a glass spherical lens, the ninth lens 10 is a glass spherical lens, and the tenth lens 11 is a glass aspheric lens.

[0041] The first lens 1 ...

Embodiment 2

[0057] see Figure 7 , Figure 7 This is an optical structure diagram of an ultra-high-resolution micro-projection lens provided in Embodiment 2 of the present invention. This embodiment does not use the galvanometer (XPR), and the conventional resolution of 1080P is achieved by adjusting the back intercept. The specific parameters are shown in Table 3:

[0058] table 3

[0059]

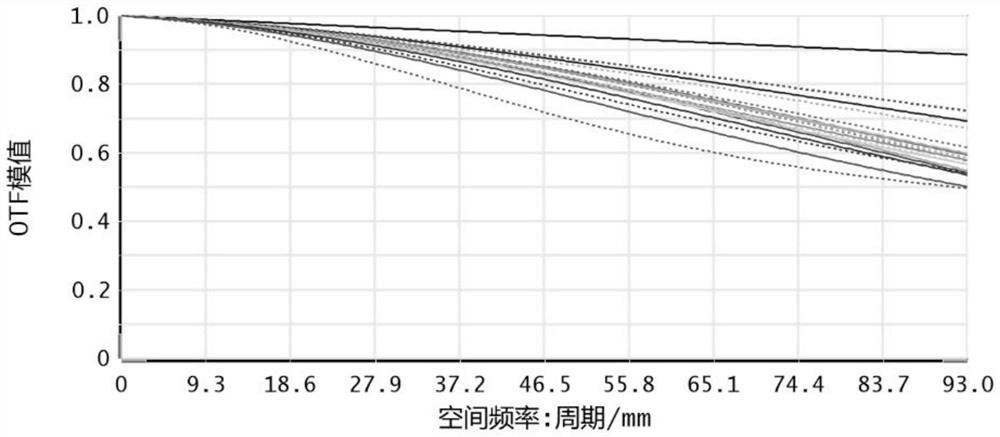

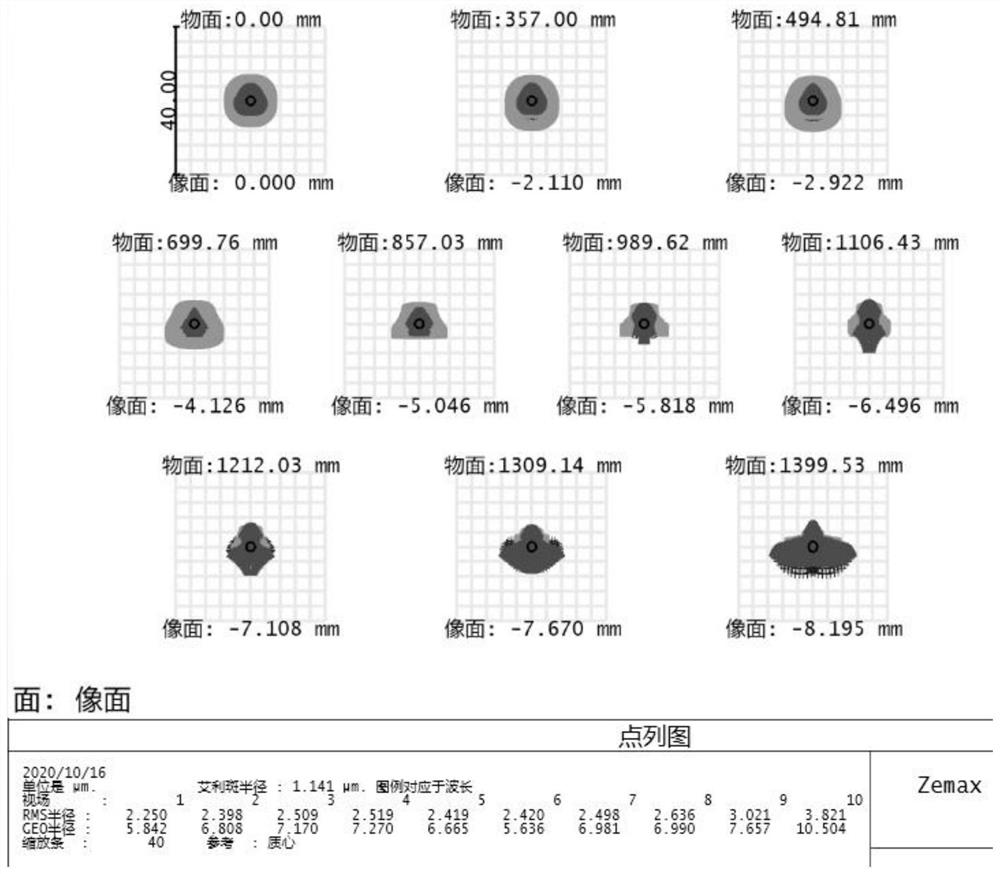

[0060] According to the lens parameters described in Table 3, it can be obtained as follows: Figure 7 Miniature projection lens shown. Figure 8 It is the image of the MTF of the whole field of view changing with the spatial frequency, and the transfer function of each field of view is MTF>0.45 at the spatial frequency of 93lp / mm. Figure 9 is the spot diagram of each field of view, the spot size of each field of view has become larger due to the existence of spherical aberration, but the RMS of the full field of view is still smaller than the pixel size (5.4μ). Figure 10 In the middle, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com