Slave cylinder with coolant channel in a plastic housing component; and clutch actuation device

A technology of housing assembly and operating device, which is applied to fluid-driven clutches, non-mechanical-driven clutches, clutches, etc., can solve the problems of high manufacturing cost and high total weight, and achieve the advantages of reducing manufacturing cost, simplifying manufacturing process, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The drawings are merely schematic in nature and are used only to aid in the understanding of the invention. Identical elements are provided with the same reference numerals. Features of different embodiments can also be freely combined with one another.

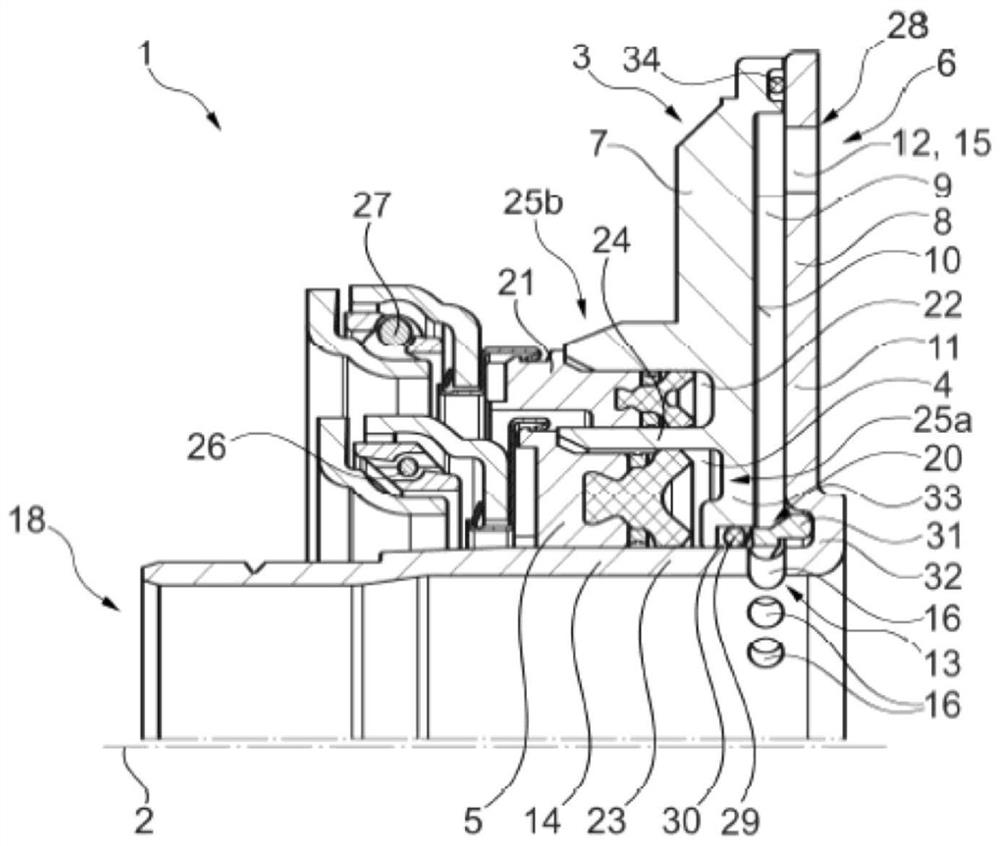

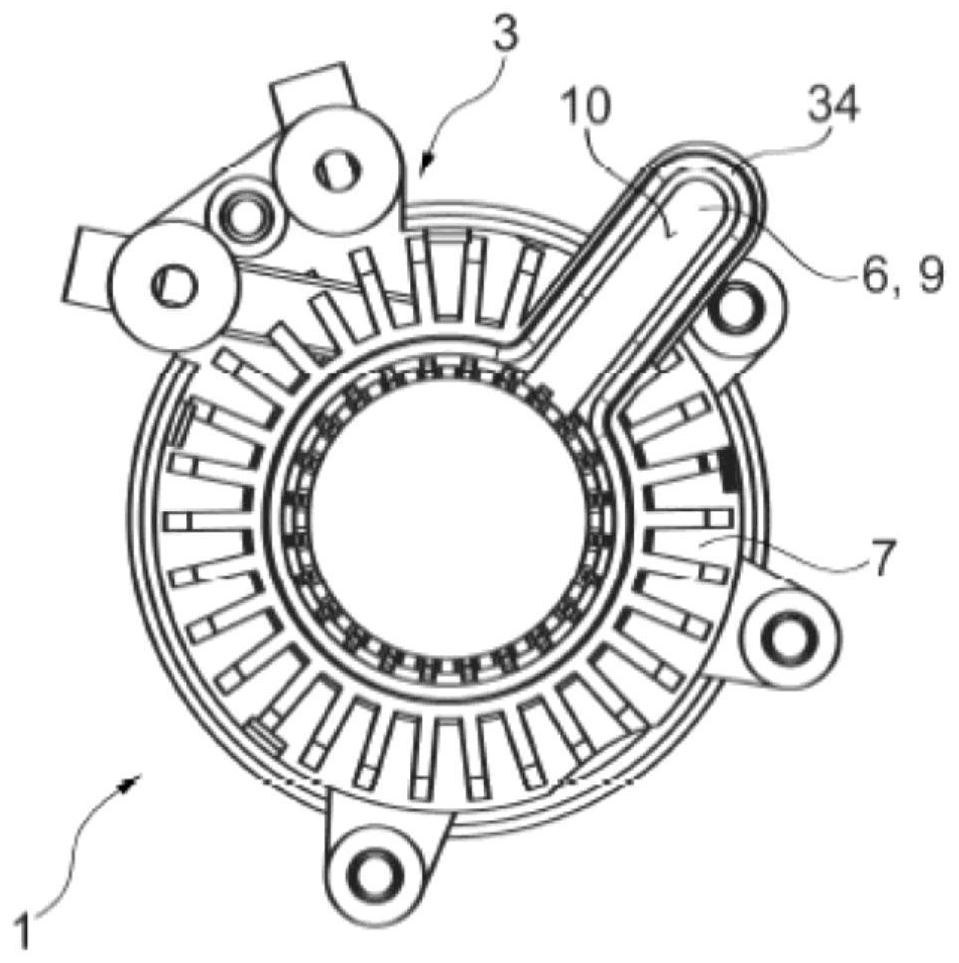

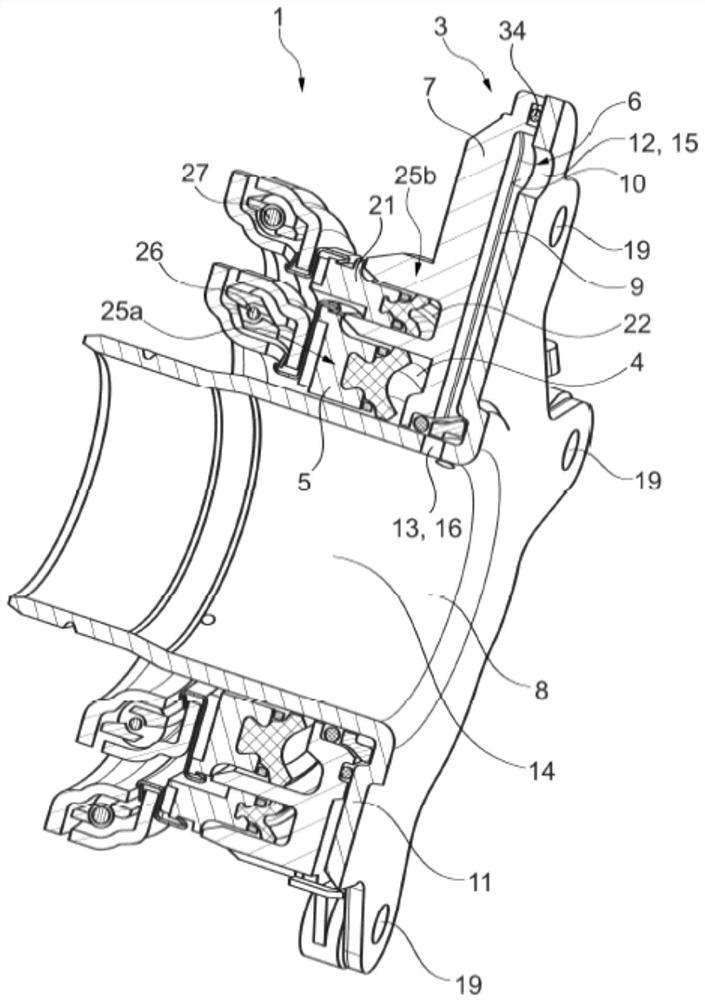

[0027] figure 1 The structure of the concentric slave cylinder 1 (CSC / "Concentric Slave Cylinder-concentric slave cylinder") of the present invention is shown. The slave cylinder 1 implemented according to the first embodiment is designed as a double slave cylinder. The slave cylinder 1 is thus used in operation to actuate two clutches of the motor vehicle drivetrain, for example two partial clutches of a dual clutch. The slave cylinder 1 is implemented in the form of a hydraulic slave cylinder 1 . The slave cylinder 1 is implemented as a concentric slave cylinder 1 . Accordingly, the slave cylinder 1 has an annular extension / design as a whole. During operation, the slave cylinder 1 is an integral part of the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com